This is a multiple question thread on rebuilding a CVA 45 percussion rifle. It was a kit rifle. The barrel was cut to 24" and bore is a rusty mess. I can get it cheap. I understand how the breech plug is installed in these guns. I want to remove the breech plug and drill out the barrel. Then put a liner in it or ream and make it a smooth bore. The taking out of the breech plug is not a problem. Questions are about putting it back. I want to remove the assembly the nipple fits in and convert it to flint. After putting the breech plug back I want to drill or machine the threads out and retap for a vent. Would go next size up in a standard, not metric thread. Will a CVA flint type lock work? Are the CVA locks hard to find? This is more of a learning type rebuild on the cheap. Figure the lock will cost more than the rifle is worth.

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CVA rebuild

- Thread starter theoldredneck

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Food for thought;

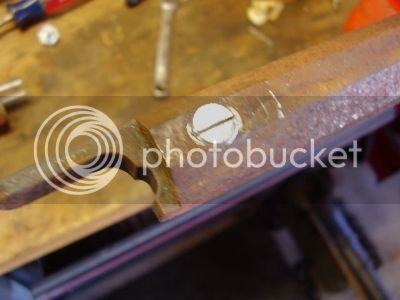

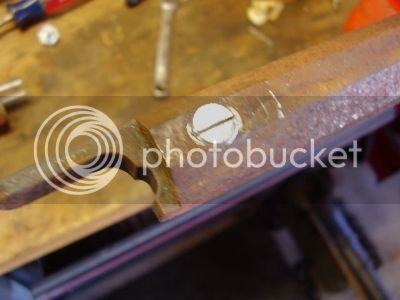

Not my project,, someone elses. That's the stock 10mm hole and threads.

Not my project,, someone elses. That's the stock 10mm hole and threads.

zimmerstutzen

70 Cal.

- Joined

- Apr 2, 2009

- Messages

- 5,845

- Reaction score

- 1,199

I had a local smith ream a bobcat barrel to smooth. He never removed the breech.

Thank you Sir, had not thought about finding a metric bolt that would fit existing threads.

I can bore and ream without pulling the breech plug. Would pull it if I put a liner in. Amount of metal between base of screw holes etc and bore will decide that. Hoping for a smooth bore on this one.

I can bore and ream without pulling the breech plug. Would pull it if I put a liner in. Amount of metal between base of screw holes etc and bore will decide that. Hoping for a smooth bore on this one.

nwtradegun

50 Cal.

- Joined

- Jan 19, 2011

- Messages

- 1,496

- Reaction score

- 17

try evil bay or l and r locks. they make replacement locks for a varity of guns.

zimmerstutzen

70 Cal.

- Joined

- Apr 2, 2009

- Messages

- 5,845

- Reaction score

- 1,199

An old cva can be a good springboard into a fine looking customized gun. It takes a little imagination and a little know how.

Saw a production gun barrel the had been draw filed to a swamped profile. Lotta work but looked good.

Saw a production gun barrel the had been draw filed to a swamped profile. Lotta work but looked good.

- Joined

- Aug 15, 2010

- Messages

- 4,727

- Reaction score

- 4,379

I've said it before...that's my favorite cva conversion of all time! What an awesome rifle!

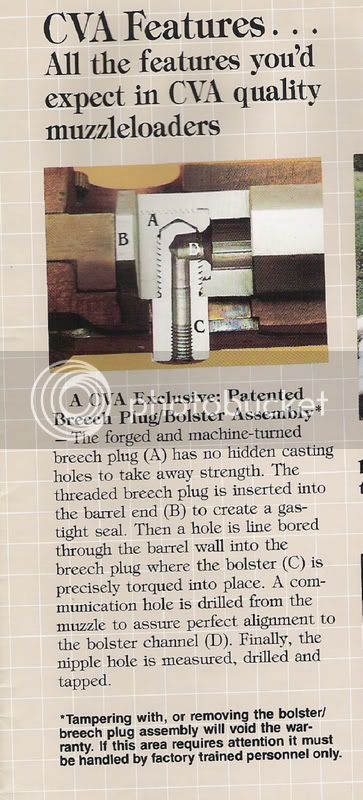

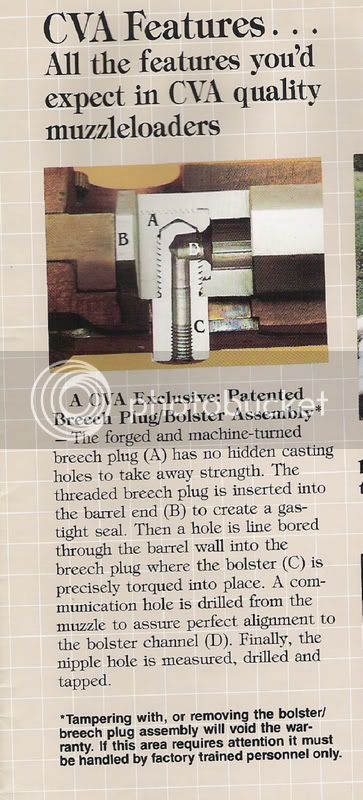

This might help if you decide to pull it.

That breech plug is "cross drilled" to insert the drum, then indexed from the muzzle. So the breech threads are buggered up a bit from the cross drilling. You really need to be careful when pulling the plug so's the barrel/breech threads don't get damaged.

The factory drum is 10mm x 1.25 pitch, check you local hardware store.

That breech plug is "cross drilled" to insert the drum, then indexed from the muzzle. So the breech threads are buggered up a bit from the cross drilling. You really need to be careful when pulling the plug so's the barrel/breech threads don't get damaged.

The factory drum is 10mm x 1.25 pitch, check you local hardware store.

The way they do their breech plug is why I had thought about drilling a size larger. Project is on hold. Guy is now asking double what he was and I am not paying any more than we agreed on.

Similar threads

- Replies

- 17

- Views

- 570

Latest posts

-

-

FOR SALE 0.502 round ball x approximately 425 rounds.

- Latest: AZ Muzzleloaders

-

-

FOR SALE 36 caliber, 0.375 pistol revolver round ball x 350 rounds

- Latest: AZ Muzzleloaders

-

-

-

-

-

-

FOR SALE 0.402 round ball x 570 rounds

- Latest: AZ Muzzleloaders