Herb

54 Cal.

- Joined

- Mar 19, 2004

- Messages

- 1,954

- Reaction score

- 445

Lyman's "Black Powder Handbook & Loading Manual, 2nd edition", lists loads of 80, 90, 100, 110 and 120 grains of Goex 2F and 3F powder with .530 roundballs and .015 pre lubed OxYoke patches in a 32" one in 60 twist barrel. They cleaned the bore after each five shots. The 3F velocities with 80, 90, 110 and 120 gains are lower than those shown for Goex 2F. This is not what we would expect, so I tested these powders.

I used my .54 Hawken I built with a 32" Douglas barrel, .530 Buffalo Bullet Company swaged roundballs and Eddie May cast .530's and CCI 11 caps. There was no difference in accuracy or velocity. I used Goex 3F powder I bought in August at the RM Natnl Rendezvous and Goex 2F. Patches were .015 OxYoke with thin 7/8" diameter leather overpowder wads or later 5/8" diameter 1/4" thick wool OPWs. Lube was spit in one test, then my cleaning solution of one part Murphy Oil Soap to five parts of 70% rubbing alcohol and six parts hydrogen peroxide. I reasoned that the "patch lube" really functions more as a bore cleaner (as spit does) than a real lubricant. It worked well. I did not wipe between shots, except as explained below.

I shot from sandbag rests over my Oehler 35P chronograph at 50 yard targets. Because I wanted to test for accuracy at the same time, I hose-clamped a Weaver 4X scope to the rifle. There was some parallax at 50 yards, which I tried to minimize by consistent holding. I could hold on a bullet hole and was confident of all holding. Of course things did not go smoothly. The .015 OxYoke patches tore, as on the second target from the left, bottom. I had to add an OPW, first 7/8" diameter thin leather, lubed with cleaner mix. Ran out of them and went to the wool OPWs.

The next change was to dampen a cleaning patch with the lube-cleaner solution and use it on the cleaning jag as I seated the ball. This process worked so well I could use the same "cleaning" patch to seat five or six balls with it. If the chronograph failed to read, or the first shot with a powder charge change was much lower than the rest of the string, or a patch tore, I fired more to get at least five good readings.

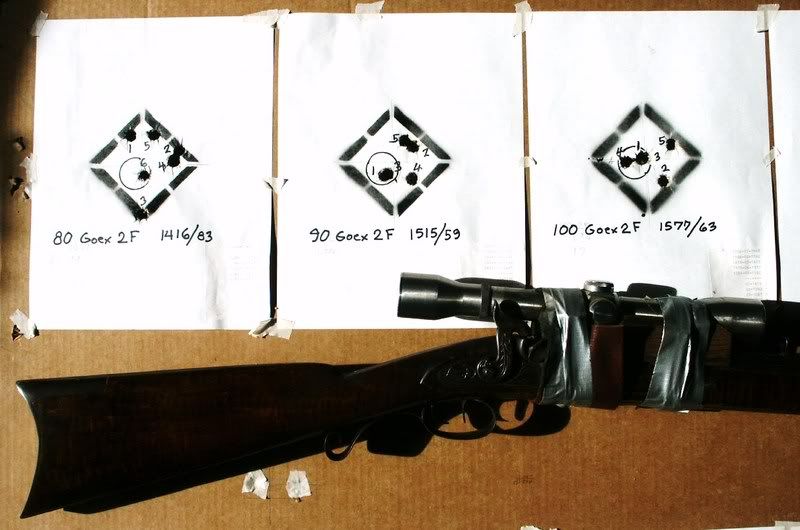

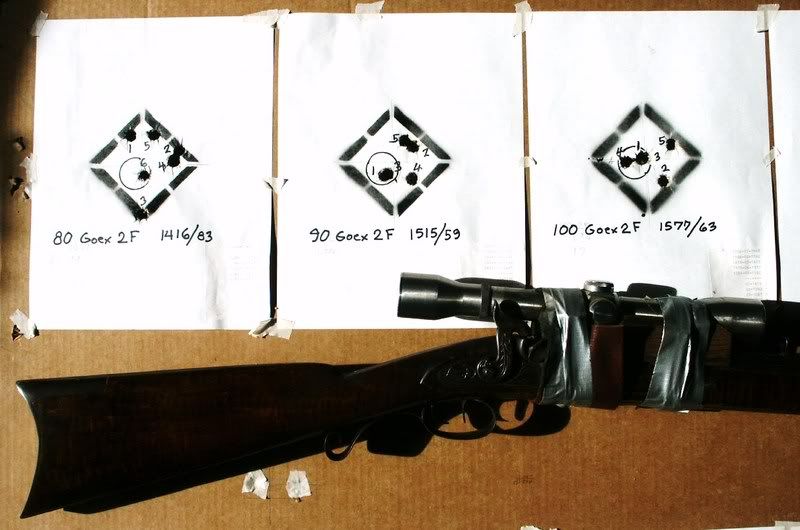

I cleaned after each powder charge test, before the 10 grain increase. Doing this, I found there was a hard fouling ring where the ball seated, and I scrubbed this out and dried the bore. I do not know if it affected accuracy. The targets below were shot with Goex 2F. The number 1416 is the five shot velocity average, and 83 was the velocity spread. The 1 1/8" circle on each target encloses 13 shots from the six targets with Goex 2F.

Targets below were 110 and 120 grains of Goex 2F. My measure at full extension did not look as if it moved far enough to be 120 grains, so I shot the target on the right using two 60 grain charges. No difference. These 2F targets were shot with the .015 OxYoke patches and leather OPW.

The targets below were shot with Goex 3F. Target on left had OxYoke patches and an OPW. Next target had red 10 ounce cotton duck and spit lube, so did the 90 grain target, neither with an OPW. The holes at the top right and bottom of the target are fliers due to blown patches. Eight shots at this target.

Targets below were fired on three different days due to radio signal chronograph interference. 100 grains was with the 10 ounce duck, seven shots with the cleaning patch on the seating jag. Next day the 110 grains of 3F with .015 OxYoke and OPW, no wiping. Next day, 120 grains of 3F with .015 OxYoke and OPW. First three shots I cleaned after each shot. Then next five fired with no cleaning, except for the patch on the seating jag.

Most groups were large, but not due to holding. But the velocities of the charges and 2F and 3F should be representative, even with the patch and lube changes.

From all similar .54 caliber chronographing I've done, here are the charges, number of shots, mean velocity and extreme velocity spread. First, with Goex 3F:

80 grains, 74 shots, mean 1615 fps, ES 61 fps

90 gr, 41 shots, M 1676, ES 69

100 gr, 21 shots, M 1745, ES 87

110 gr, 9 shots, M 1850, ES 120

120 gr, 11 shots, M 1871, ES 92

120 gr, 14 shots, M 1957, ES 128( my Leman, which has a tighter bore)

With Goex 2F:

80 gr, 16 shots, M 1398, ES 55

90 gr, 5 shots, M 1515, ES 59

100 gr, 5 shots, M 1577, ES 63

110 gr, 5 shots, M 1591, ES 21

120 gr, 18 shots, M 1685, ES 46

120 gr, 22 shots, M 1868, ES 64 (4 rifles 4-13 years ago)

120 gr, 10 shots, M 1783, ES 59 (Moosic, PA powder, my 200 yard test with scoped Hawken)

120 gr, 9 shots, M 1879, ES 104 (my Leman)

In my testing, the Goex 3F produced more velocity than the Goex 2F. I have no way to compare pressure. I have no explanation or guess for Lyman's results with these powders in the .54.

I used my .54 Hawken I built with a 32" Douglas barrel, .530 Buffalo Bullet Company swaged roundballs and Eddie May cast .530's and CCI 11 caps. There was no difference in accuracy or velocity. I used Goex 3F powder I bought in August at the RM Natnl Rendezvous and Goex 2F. Patches were .015 OxYoke with thin 7/8" diameter leather overpowder wads or later 5/8" diameter 1/4" thick wool OPWs. Lube was spit in one test, then my cleaning solution of one part Murphy Oil Soap to five parts of 70% rubbing alcohol and six parts hydrogen peroxide. I reasoned that the "patch lube" really functions more as a bore cleaner (as spit does) than a real lubricant. It worked well. I did not wipe between shots, except as explained below.

I shot from sandbag rests over my Oehler 35P chronograph at 50 yard targets. Because I wanted to test for accuracy at the same time, I hose-clamped a Weaver 4X scope to the rifle. There was some parallax at 50 yards, which I tried to minimize by consistent holding. I could hold on a bullet hole and was confident of all holding. Of course things did not go smoothly. The .015 OxYoke patches tore, as on the second target from the left, bottom. I had to add an OPW, first 7/8" diameter thin leather, lubed with cleaner mix. Ran out of them and went to the wool OPWs.

The next change was to dampen a cleaning patch with the lube-cleaner solution and use it on the cleaning jag as I seated the ball. This process worked so well I could use the same "cleaning" patch to seat five or six balls with it. If the chronograph failed to read, or the first shot with a powder charge change was much lower than the rest of the string, or a patch tore, I fired more to get at least five good readings.

I cleaned after each powder charge test, before the 10 grain increase. Doing this, I found there was a hard fouling ring where the ball seated, and I scrubbed this out and dried the bore. I do not know if it affected accuracy. The targets below were shot with Goex 2F. The number 1416 is the five shot velocity average, and 83 was the velocity spread. The 1 1/8" circle on each target encloses 13 shots from the six targets with Goex 2F.

Targets below were 110 and 120 grains of Goex 2F. My measure at full extension did not look as if it moved far enough to be 120 grains, so I shot the target on the right using two 60 grain charges. No difference. These 2F targets were shot with the .015 OxYoke patches and leather OPW.

The targets below were shot with Goex 3F. Target on left had OxYoke patches and an OPW. Next target had red 10 ounce cotton duck and spit lube, so did the 90 grain target, neither with an OPW. The holes at the top right and bottom of the target are fliers due to blown patches. Eight shots at this target.

Targets below were fired on three different days due to radio signal chronograph interference. 100 grains was with the 10 ounce duck, seven shots with the cleaning patch on the seating jag. Next day the 110 grains of 3F with .015 OxYoke and OPW, no wiping. Next day, 120 grains of 3F with .015 OxYoke and OPW. First three shots I cleaned after each shot. Then next five fired with no cleaning, except for the patch on the seating jag.

Most groups were large, but not due to holding. But the velocities of the charges and 2F and 3F should be representative, even with the patch and lube changes.

From all similar .54 caliber chronographing I've done, here are the charges, number of shots, mean velocity and extreme velocity spread. First, with Goex 3F:

80 grains, 74 shots, mean 1615 fps, ES 61 fps

90 gr, 41 shots, M 1676, ES 69

100 gr, 21 shots, M 1745, ES 87

110 gr, 9 shots, M 1850, ES 120

120 gr, 11 shots, M 1871, ES 92

120 gr, 14 shots, M 1957, ES 128( my Leman, which has a tighter bore)

With Goex 2F:

80 gr, 16 shots, M 1398, ES 55

90 gr, 5 shots, M 1515, ES 59

100 gr, 5 shots, M 1577, ES 63

110 gr, 5 shots, M 1591, ES 21

120 gr, 18 shots, M 1685, ES 46

120 gr, 22 shots, M 1868, ES 64 (4 rifles 4-13 years ago)

120 gr, 10 shots, M 1783, ES 59 (Moosic, PA powder, my 200 yard test with scoped Hawken)

120 gr, 9 shots, M 1879, ES 104 (my Leman)

In my testing, the Goex 3F produced more velocity than the Goex 2F. I have no way to compare pressure. I have no explanation or guess for Lyman's results with these powders in the .54.