Seems to me, the best place to encounter a problem would be in large bore/heavy projectile guns. The .72 ball will accelerate much slower than a .32 ball will. Just me thinking, but seems the slower acceleration rate would lead to much higher pressure than a faster ball. The Remington example is a revolver. The ball leaves cylinder rather rapidly and you have venting between the cylinder and barrel. A long barreled rifle should build more pressure because of barrel length. That said, maximum pressure should be the point where all the powder burns. As the ball moves down a long barrel, wouldn't the pressures reduce the further the ball is from the breech? I do know that in my Gibbs 4.51, I can tell the difference in recoil if I shoot the same loads of 2f and 3f. ie..70grs 2f or 70grs 3f.

-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4F Black Powder Question

- Thread starter fjrdoc

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Status

- Not open for further replies.

It's smokeless that did the damage.There were a couple of guys on youtube that did this with a CVA Kentucky rifle. They kept loading more and more until they filled the barrel leaving only enough room for the ball. The stock was damaged but that was more from the contraption holding the rifle than the load. The rest showed no apparent damage.

Worth watching!

However I am not putting the link up.

- Joined

- Nov 1, 2018

- Messages

- 3,224

- Reaction score

- 2,285

I knew someone who used to shoot his 32 cal with 4F in the main charge. It was something like 20-30 grains and it was tightly packed in a paper ball. I wouldn’t recommend it but it can be done. I would just use it as my priming for every shot until its down to around 1lb. 1lb of 4f lasts me a very long time.

I shoot my .75 Bess with 4f.Seems to me, the best place to encounter a problem would be in large bore/heavy projectile guns. The .72 ball will accelerate much slower than a .32 ball will. Just me thinking, but seems the slower acceleration rate would lead to much higher pressure than a faster ball. The Remington example is a revolver. The ball leaves cylinder rather rapidly and you have venting between the cylinder and barrel. A long barreled rifle should build more pressure because of barrel length. That said, maximum pressure should be the point where all the powder burns. As the ball moves down a long barrel, wouldn't the pressures reduce the further the ball is from the breech? I do know that in my Gibbs 4.51, I can tell the difference in recoil if I shoot the same loads of 2f and 3f. ie..70grs 2f or 70grs 3f.

Folk just don't understand how black powder works.

They think that because it is an explosive it likes to explode things.

It doesn't. It doesn't anymore than the gas in your car turns your car into an incinerator.

As long as whatever is sat on the powder is sat on the powder and can escape with the powder as it changes in its nature all be it rapidly all will be well. It matters not if one granulation produces several thousand more psi during normal operation, it's still way behind what would cause damage.

Projectile wise black powder is of low yield. There are limits to its performance. Not because things get dangerous. No it is because it's efficiency is low, however it is in fact very forgiving in that you can stick an unbelievable amount of weight on it and it will still move it off for you naturally dampening itself so as to not cause damage. This is something that nitro can not do so easily and safely without extensive testing and intricate formulations!

Look, the best thing to do is those that use it keep using it.

Them that are petrified or experts in non factual assumption and assertions of non evidence send all the superfine graded stuff to me and I will do my level best, at no extra charge to yourselves, to dispose of it safely.

I’ve long argued about 4F being used in revolvers during the Civil War and afterwards when they morphed into metallic cartridges.

I seem to recall reading that ammunition back then was tested for it's strength as was the powder itself. I also recall reading of guns blowing up, hence the need for testing.

Ammunition wasn't just loaded "willy-nilly" with any old powder.

Sam Fadala did a series of tests trying to blow up guns in his Black Powder Handbook. All tests were with DuPont 3F powder. He measured barrel diameter with micrometer every few inches after each shot.

The first was just a test barrel with bolster and percussion lock, .58 caliber, 1” x 36”, 1:72” twist, groove depth .010”, barrel wall .2”. He fired shots #1-#5 with 100, 200, 300, 400 and 500 grains of powder and a 600 grain Maxi conical of .570 caliber, seated on the powder. No change in measurements. Shot #6 was 400 grains powder with 2 conicals seated. No change. Shot #7 was 500 grains powder and 3 conicals seated, no change. Shot #8 was 400 grains powder and 2 conicals, but separated from the powder by 19”. The barrel blew up.

The second series used a duplicate barrel to the first, but built into a finished gun, percussion. He duplicated the entire series, and had the same result, no change in the barrel until it blew up with the Maxis separated from the powder.

The third series used a .50 caliber Navy Arms Morse rifle with brass receiver and a drum and nipple instead of a bolster, chosen because it was supposedly weaker. He repeated the same series as in the first two with conicals, but then also did it using patched round balls. The shot with conicals separated from the powder did not damage this gun. So, he added a shot, 300 grains 4F and 3 Maxies separated. No change. He gave up trying to blow that one up with black powder, did a shot with 200 grains Bullseye and 1 maxi seated normally, the gun blew up.

Spence

The first was just a test barrel with bolster and percussion lock, .58 caliber, 1” x 36”, 1:72” twist, groove depth .010”, barrel wall .2”. He fired shots #1-#5 with 100, 200, 300, 400 and 500 grains of powder and a 600 grain Maxi conical of .570 caliber, seated on the powder. No change in measurements. Shot #6 was 400 grains powder with 2 conicals seated. No change. Shot #7 was 500 grains powder and 3 conicals seated, no change. Shot #8 was 400 grains powder and 2 conicals, but separated from the powder by 19”. The barrel blew up.

The second series used a duplicate barrel to the first, but built into a finished gun, percussion. He duplicated the entire series, and had the same result, no change in the barrel until it blew up with the Maxis separated from the powder.

The third series used a .50 caliber Navy Arms Morse rifle with brass receiver and a drum and nipple instead of a bolster, chosen because it was supposedly weaker. He repeated the same series as in the first two with conicals, but then also did it using patched round balls. The shot with conicals separated from the powder did not damage this gun. So, he added a shot, 300 grains 4F and 3 Maxies separated. No change. He gave up trying to blow that one up with black powder, did a shot with 200 grains Bullseye and 1 maxi seated normally, the gun blew up.

Spence

- Joined

- Jun 4, 2014

- Messages

- 3,936

- Reaction score

- 4,711

If you have a chronograph, could you shoot your standard load of 3f, then work up a load with 4f that give you the same fps? I have no idea, but it seems if you work it up that way, you would be in a safe zone. Experts, pls comment cause I aint no expert.

A chronograph is not a pressure gauge, and it is only one part of developing an efficient, effective load. It will give you an indication, in the form of an accurate read on velocity but, velocity can actually remain the same or even go down with higher pressure. As I said before there are a lot of factors affecting pressure in a gun barrel, to name a few: friction from actual bore diameter difference to projectile diameter, roughness of the interior of the barrel, fouling, patch thickness and material if you are using one, how tightly the projectile is seated, how hot the cap is on a percussion gun, among others.

If you are using a chronograph and you reach a plateau in velocity, or a diminishing return on the amount of powder to velocity, you can logically determine you have reached the peak point of efficiency with that powder in that load and you'll only be adding pressure and wasting powder to add more.

There are other ways of getting an idea of pressure, like recoil, and in a percussion gun, given everything else is in proper condition (springs, nipples, etc.) blowback through the nipple.

Adding all of these things together with a chronograph reading, you can begin to build a picture of what your particular rifle is doing, but without an actual pressure barrel with a piezoelectric gauge or copper/lead crusher, you are never going to know exactly what pressure any given load is going to provide. Even with the testing equipment, the reading will only apply to that barrel, and is why data producers say to reduce by 10% their data when loading for your particular gun.

Thing to do is start out low and work your way up making careful observations, taking into consideration things like, as fouling builds, so will pressure, with the same load, given the resistance created. Problem comes because a lot of folks don't have this kind of time, patience or attention to detail. Hence the lawyers get involved.

Fact of the matter is the old timers stopped putting powder in when they no longer got a good return on their investment and that was their "load". They used the least amount of powder they could to get the results they needed, whether that powder be 2f, 3f or 4f

Take a look at Lyman's regular reloading manuals, they are one example of a good explanation of pressure.

Question for the experts about a proposed load and rifle. Say you had a 62 caliber rifle with a 30” barrel, shooting a patched roundball over a 100 grain powder main charge with a granulation finer than 3F. Would it be accurate and safe to shoot? Curious what the experts have to say about this specific load.

I'm not posting the video because not allowed but if someone wants to see it, go to youtube and search black powder test. Two guys with a Kentucky rifle do a double charge, then they fill the barrel and then they try smokeless powder to finally do it in. Surprisingly 80 gr (by volume) of H110 doesn't blow the gun up but it does bulge the barrel.

I remember reading that Spence.Sam Fadala did a series of tests trying to blow up guns in his Black Powder Handbook. All tests were with DuPont 3F powder. He measured barrel diameter with micrometer every few inches after each shot.

The first was just a test barrel with bolster and percussion lock, .58 caliber, 1” x 36”, 1:72” twist, groove depth .010”, barrel wall .2”. He fired shots #1-#5 with 100, 200, 300, 400 and 500 grains of powder and a 600 grain Maxi conical of .570 caliber, seated on the powder. No change in measurements. Shot #6 was 400 grains powder with 2 conicals seated. No change. Shot #7 was 500 grains powder and 3 conicals seated, no change. Shot #8 was 400 grains powder and 2 conicals, but separated from the powder by 19”. The barrel blew up.

The second series used a duplicate barrel to the first, but built into a finished gun, percussion. He duplicated the entire series, and had the same result, no change in the barrel until it blew up with the Maxis separated from the powder.

The third series used a .50 caliber Navy Arms Morse rifle with brass receiver and a drum and nipple instead of a bolster, chosen because it was supposedly weaker. He repeated the same series as in the first two with conicals, but then also did it using patched round balls. The shot with conicals separated from the powder did not damage this gun. So, he added a shot, 300 grains 4F and 3 Maxies separated. No change. He gave up trying to blow that one up with black powder, did a shot with 200 grains Bullseye and 1 maxi seated normally, the gun blew up.

Spence

He taught me a lot about the nature of black powder.

Thanks for the accurate copy.

Following on from Spence's reference many don't appreciate why a muzzloaders barrel/s have the wall thickness that they do.

It is not because they use black powder directly but is all to do with the nature of black powder when a cavity exists.

Under those conditions we do indeed have a potential bomb.

Unfortunately for muzzleloaders the opportunity of a cavity occuring compared to the self contained cartridge rises many times over.

This is the reason their barrels tend to be thick walled. It is not a minimum requirement but an over engineering application.

Does not many a nitro fuelled firearm that produces higher pressures have thinner or equal thickness barrel walls!

You can observe , completely not recommended practices today of people building from low schedule mild steel pipe and fittings, shotguns and discharging shotgun cartridges in their creations!

Once more, powder granulation is not dangerous in any grade in small arms of sound condition.

Only cavities or barrel obstructions off the charge are dangerous. This is a proven fact. There is no proven fact that a fine granulation can equal the destructive capabilities of a cavity and a cavity is not even granulation fussy at all in the first place.

There is indeed a cannon section to this wonderful site. Cross-reference to aspects of cannon large or small, naval or other has no bearing at all to the use of 4f in a small arm.

With regards to a revolver discussed earlier and heavy bullets letting go.

We don't know all the facts thus leading to yet more assuming. Was a cavity created from previous shots? Was there a delayed ignition or stepped ignition? We don't know completely do we!

It is not because they use black powder directly but is all to do with the nature of black powder when a cavity exists.

Under those conditions we do indeed have a potential bomb.

Unfortunately for muzzleloaders the opportunity of a cavity occuring compared to the self contained cartridge rises many times over.

This is the reason their barrels tend to be thick walled. It is not a minimum requirement but an over engineering application.

Does not many a nitro fuelled firearm that produces higher pressures have thinner or equal thickness barrel walls!

You can observe , completely not recommended practices today of people building from low schedule mild steel pipe and fittings, shotguns and discharging shotgun cartridges in their creations!

Once more, powder granulation is not dangerous in any grade in small arms of sound condition.

Only cavities or barrel obstructions off the charge are dangerous. This is a proven fact. There is no proven fact that a fine granulation can equal the destructive capabilities of a cavity and a cavity is not even granulation fussy at all in the first place.

There is indeed a cannon section to this wonderful site. Cross-reference to aspects of cannon large or small, naval or other has no bearing at all to the use of 4f in a small arm.

With regards to a revolver discussed earlier and heavy bullets letting go.

We don't know all the facts thus leading to yet more assuming. Was a cavity created from previous shots? Was there a delayed ignition or stepped ignition? We don't know completely do we!

Last edited:

rodwha

58 Cal.

Following on from Spence's reference many don't appreciate why a muzzloaders barrel/s have the wall thickness that they do.

It is not because they use black powder directly but is all to do with the nature of black powder when a cavity exists.

Under those conditions we do indeed have a potential bomb.

Unfortunately for muzzleloaders the opportunity of a cavity occuring compared to the self contained cartridge rises many times over.

This is the reason their barrels tend to be thick walled. It is not a minimum requirement but an over engineering application.

Does not many a nitro fuelled firearm that produces higher pressures have thinner or equal thickness barrel walls!

You can observe , completely not recommended practices today of people building from low schedule mild steel pipe and fittings, shotguns and discharging shotgun cartridges in their creations!

Once more, powder granulation is not dangerous in any grade in small arms of sound condition.

Only cavities or barrel obstructions off the charge are dangerous. This is a proven fact. There is no proven fact that a fine granulation can equal the destructive capabilities of a cavity and a cavity is not even granulation fussy at all in the first place.

There is indeed a cannon section to this wonderful site. Cross-reference to aspects of cannon large or small, naval or other has no bearing at all to the use of 4f in a small arm.

With regards to a revolver discussed earlier and heavy bullets letting go.

We don't know all the facts thus leading to yet more assuming. Was a cavity created from previous shots? Was there a delayed ignition or stepped ignition? We don't know completely do we!

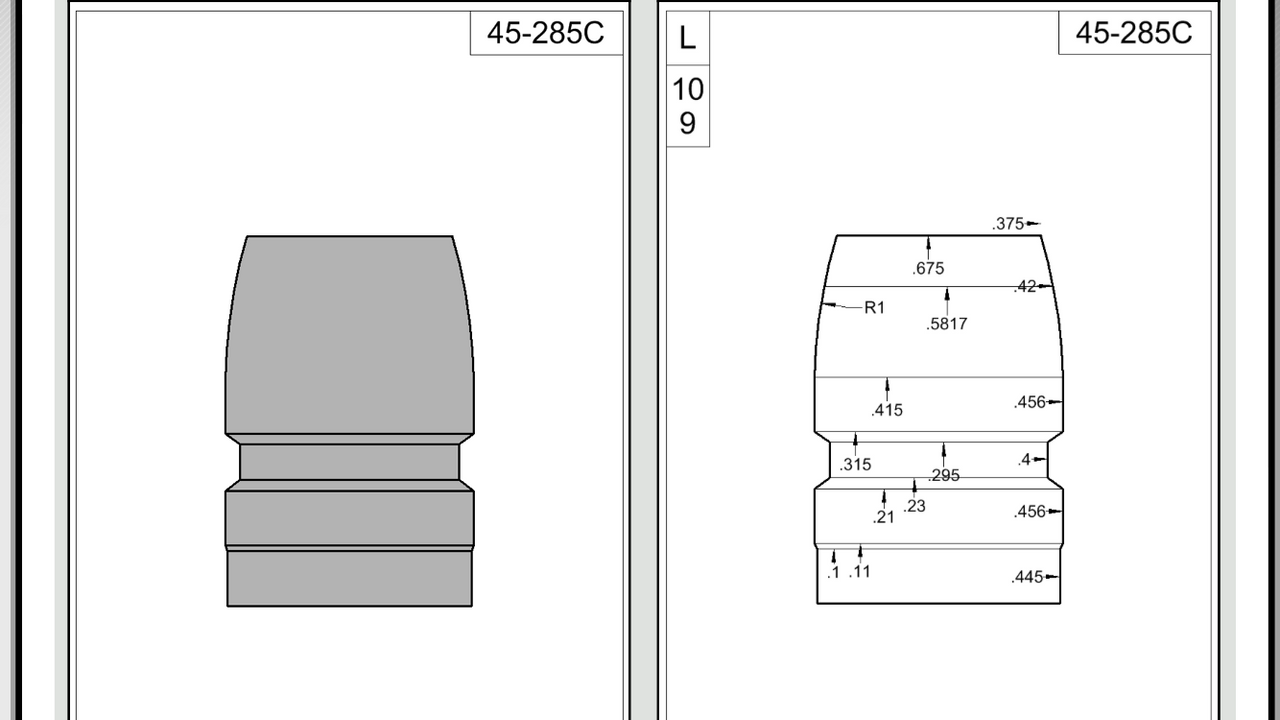

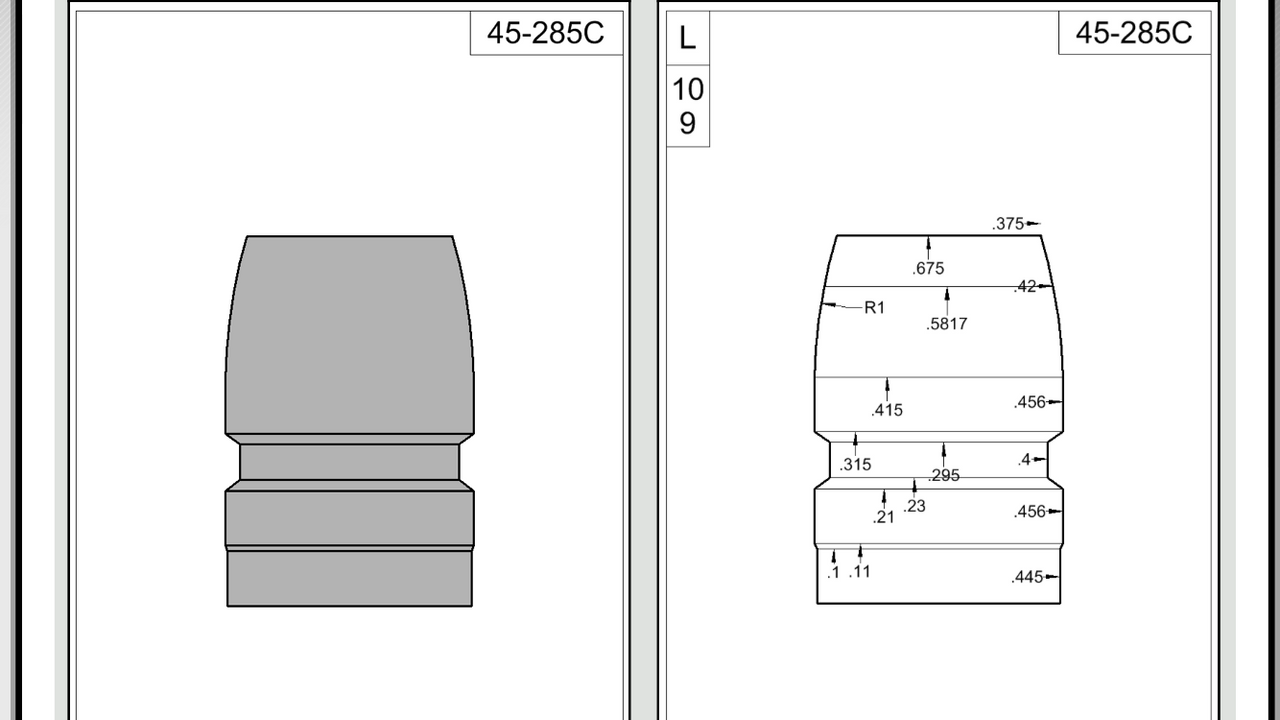

There couldn’t have been room for a cavity. In the past every time I posted a link to my designs my post was deleted. Maybe a pic of the design will be found to be ok.

I have no clue as to what his ASM chambers ran but my bullets drop at about 0.456” so you can see that shaving even a hair of lead creates long driving bands, not to mention the heft in a compact design. But ASM was known to have quality issues too. Regardless, as you can see, there’s just no way there’s room for that much powder under that projectile.

So, we can not assume the issue was 4f then.There couldn’t have been room for a cavity. In the past every time I posted a link to my designs my post was deleted. Maybe a pic of the design will be found to be ok.

I have no clue as to what his ASM chambers ran but my bullets drop at about 0.456” so you can see that shaving even a hair of lead creates long driving bands, not to mention the heft in a compact design. But ASM was known to have quality issues too. Regardless, as you can see, there’s just no way there’s room for that much powder under that projectile.

Was the piece proofed by a known and recognised proof house?

Had the pistol potentially been subjected to misuse prior?

We don't know ALL the facts so we can not attribute the failure purely on powder granulation.

Yes/no?

- Joined

- Aug 14, 2019

- Messages

- 137

- Reaction score

- 161

Wow, I didn't think that this question would end up being so hotly debated. I didn't mean to disturb the hornets nest.

It's interesting to read about period cartridges containing what appears to be 4F powder. I asked this question not because I'm looking for increased velocity simply because I have a lot of 4F powder and I thought that maybe it could be used as a main charge to use up some of my supply.

This reminds me of a couple of hotly debated threads that I follow over on the Moparts car forum. It does seem interesting that Lyman at one time did list 4F loads in their older manuals but not in the newer ones. Certainly metallurgy has changed for the worse 50 years. It does make one wonder if legal issues have dictated the omissions.

I am a surgeon by trade and have been shooting muzzle loaders since 1976 . I am not a risk taker or some uneducated yahoo. My hunting loads for this rifle will be composed of 3F powder. I suspect that my thick-walled .45 caliber rifle barrel would be safe with 4F charges. I don't have a chamber pressure gauge to test this. I just thought I would ask for some expert opinion on this forum.

It's interesting to read about period cartridges containing what appears to be 4F powder. I asked this question not because I'm looking for increased velocity simply because I have a lot of 4F powder and I thought that maybe it could be used as a main charge to use up some of my supply.

This reminds me of a couple of hotly debated threads that I follow over on the Moparts car forum. It does seem interesting that Lyman at one time did list 4F loads in their older manuals but not in the newer ones. Certainly metallurgy has changed for the worse 50 years. It does make one wonder if legal issues have dictated the omissions.

I am a surgeon by trade and have been shooting muzzle loaders since 1976 . I am not a risk taker or some uneducated yahoo. My hunting loads for this rifle will be composed of 3F powder. I suspect that my thick-walled .45 caliber rifle barrel would be safe with 4F charges. I don't have a chamber pressure gauge to test this. I just thought I would ask for some expert opinion on this forum.

- Joined

- Mar 7, 2019

- Messages

- 432

- Reaction score

- 424

Define expert. Lol. Joking. It was a good read and I learned a few things.

Never the less fjrdoc, it ended up being a good discussion and I'm sure allot of people learned something from it, including myself. That is what the forum is about.

rodwha

58 Cal.

So, we can not assume the issue was 4f then.

Was the piece proofed by a known and recognised proof house?

Had the pistol potentially been subjected to misuse prior?

We don't know ALL the facts so we can not attribute the failure purely on powder granulation.

Yes/no?

It was not 4F but Pyrodex P.

He was the third owner of the gun, and a from a manufacturer know to have quality issues. So it’s hard to say much of anything about the condition of the gun. And I know nothing about ASM’s practices concerning proofing. I assume it was done.

What I figure is that he likely had to compress that powder tightly to get that bullet seated. I don’t have a clue as to what the cylinder diameter might be but guess it likely was undersized like most. That would produce very long driving bands. I don’t chalk it up as a granulation issue at all, but a pressure issue trying to push a big heavy chunk of lead that didn’t want to move fast enough.

It was even suggested by a few that smokeless may have been used, though I doubt that as he was want new to BP.

- Joined

- Jul 31, 2006

- Messages

- 3,886

- Reaction score

- 950

Define expert. Lol. Joking. It was a good read and I learned a few things.

My father defined "expert" as someone who did not live locally and who charged for their opinion. As in "we are going to bring in an expert".

I am a bit surprised no one offered an opinion to my question, possibly the word expert was too intimidating?Question for the experts about a proposed load and rifle. Say you had a 62 caliber rifle with a 30” barrel, shooting a patched roundball over a 100 grain powder main charge with a granulation finer than 3F. Would it be accurate and safe to shoot? Curious what the experts have to say about this specific load.

The load I asked about (62 caliber roundball over 100 grains of finer than 3F powder), I have seen referenced as the standard powder charge for the British Pattern 1800 Infantry, or Baker Rifle, in an NRA article (snippet of article showing load statement and link to article below). Based on opinions stated in this thread, there are quite a few who would not load, shoot, or be near a rifle loaded with this charge. Too dangerous. But it worked in 1800.

https://www.americanrifleman.org/articles/2017/3/16/i-have-this-old-gun-british-baker-rifle/

- Status

- Not open for further replies.

Similar threads

- Replies

- 7

- Views

- 382

- Replies

- 11

- Views

- 914