-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wire trigger/bolt spring

- Thread starter nikke

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 25, 2011

- Messages

- 8,777

- Reaction score

- 3,768

Just go down to a hobby shop and pick up some piano wire of the correct size and make one.

I've made several out of stainless flat spring stock but piano wire would be lots easier and last just as long.

I've made several out of stainless flat spring stock but piano wire would be lots easier and last just as long.

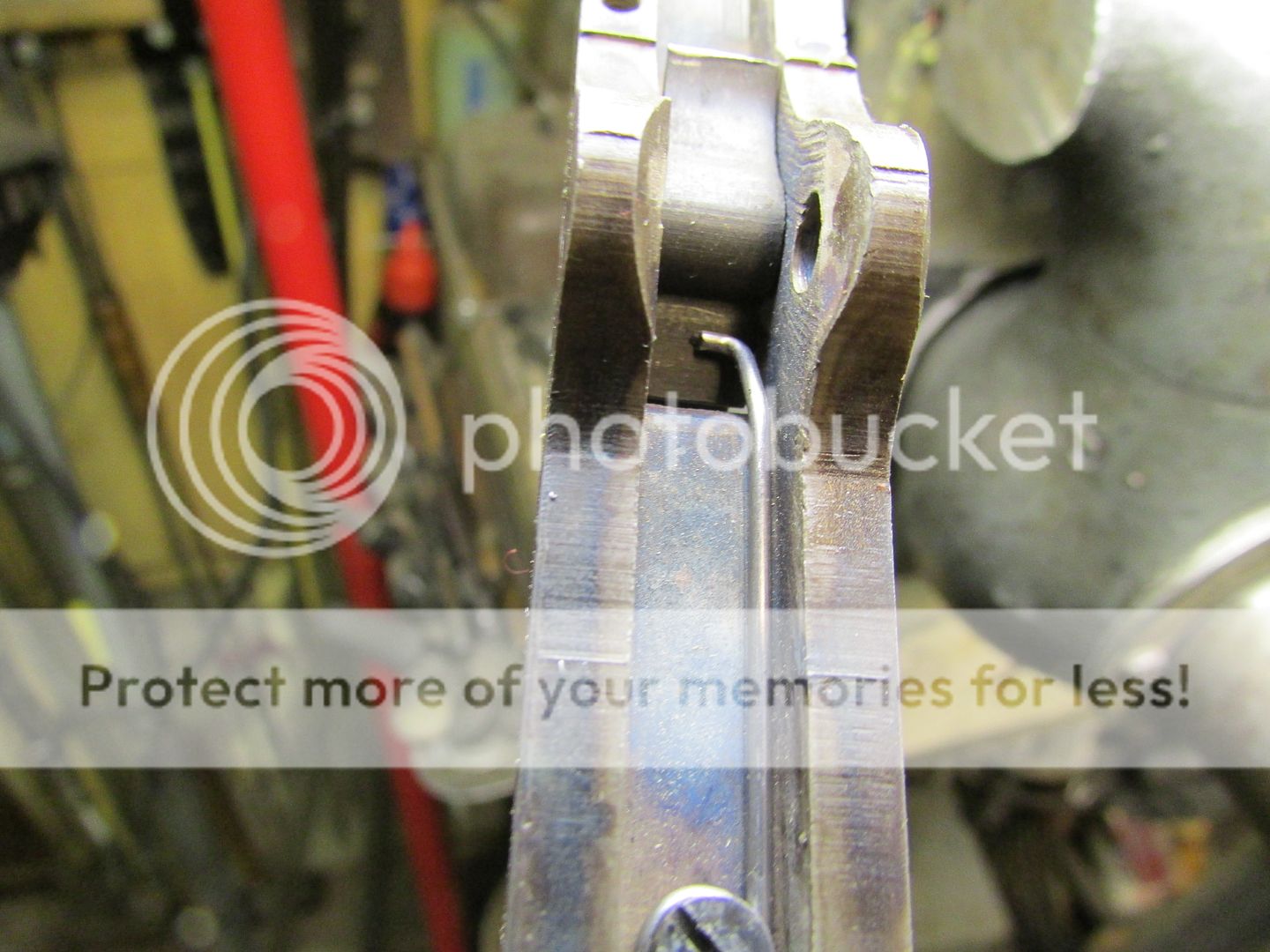

I have just fitted one in my 2nd Generation Navy, it came from Brownells and was advertised for the Single Action Army Series but fitted straight in with a tiny bit of tweaking.

I agree with M.D. in future I will buy a length of piano wire and make my own now I know the diameter.

I haven't had chance to shoot it yet but it feels lighter if that makes sense??

I agree with M.D. in future I will buy a length of piano wire and make my own now I know the diameter.

I haven't had chance to shoot it yet but it feels lighter if that makes sense??

- Joined

- Dec 25, 2011

- Messages

- 8,777

- Reaction score

- 3,768

I would go with about .050-.055 if it were me.

This is a two lever spring, one for the bolt lift and the other the trigger return.

What is the diameter of the wire spring from Brownells?

This is a two lever spring, one for the bolt lift and the other the trigger return.

What is the diameter of the wire spring from Brownells?

The wire measured 18 swg on my little gauge which equates to approximately 0.048'' if this any help? I haven't been to my local hobby shop yet but I would bet that it's sold in mm sizes now!

- Joined

- Dec 25, 2011

- Messages

- 8,777

- Reaction score

- 3,768

I was going by memory on my guess of the .050 wire diameter used for making a trigger return spring on a rifle a few months ago.

I use a fare amount of it for winding various coil and torsion springs for gun projects.

It comes in three foot lengths in packets of three from the hobby shop I buy from.

It has both the mm and thousands diameter printed on the bundle tag.

I use a fare amount of it for winding various coil and torsion springs for gun projects.

It comes in three foot lengths in packets of three from the hobby shop I buy from.

It has both the mm and thousands diameter printed on the bundle tag.

- Joined

- Dec 25, 2011

- Messages

- 8,777

- Reaction score

- 3,768

I have used a steel rod mounted in the vice and bent them to shape with vice grips around the rod.

I have copper plates for the vice jaws if holding the wire directly so as not to put dings or grip marks in the spring itself.

When using vice grips always lock the jaws on longer than will be needed so as not to mark up the finished spring.

This is a pretty simple spring to make and will not require a winding arbor or forming jig.

I have copper plates for the vice jaws if holding the wire directly so as not to put dings or grip marks in the spring itself.

When using vice grips always lock the jaws on longer than will be needed so as not to mark up the finished spring.

This is a pretty simple spring to make and will not require a winding arbor or forming jig.

I bought a pair of round wire bending pliers from Hobbycraft. They are available in a couple of sizes and work on the size of wire used for making a spring. They are just the job for the little bit of tweaking that you will invariably need too do to get the spring perfect. I found that the Brownells spring was very slightly proud of the bottom of the frame and just needed 'relaxing' a bit to get it to clear.

- Joined

- Dec 25, 2011

- Messages

- 8,777

- Reaction score

- 3,768

- Joined

- Dec 25, 2011

- Messages

- 8,777

- Reaction score

- 3,768

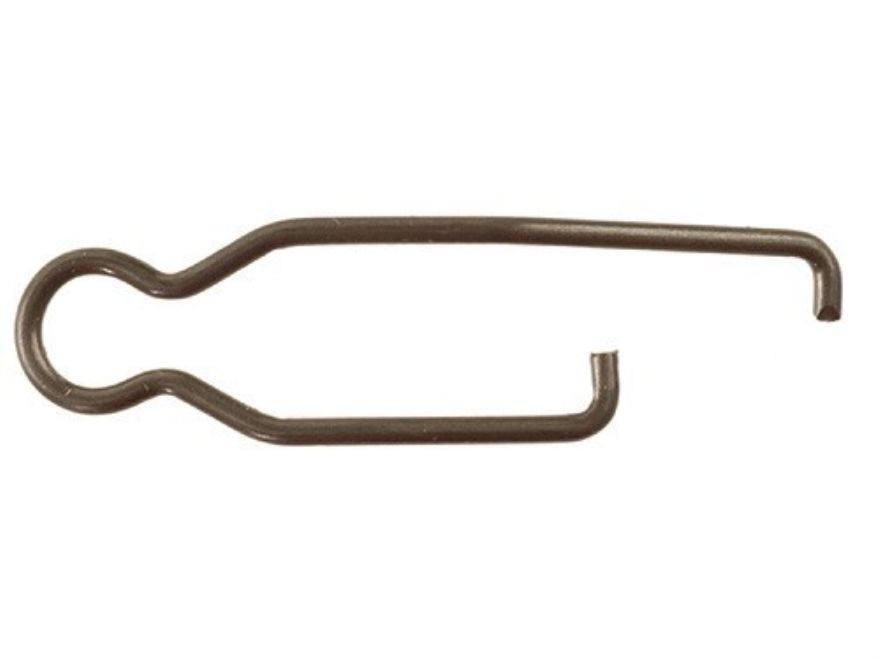

Thanks for the picture now I won't need to make one.

This would be quite an easy spring to duplicate with piano wire.

You wouldn't even need to make the choke after the cap screw circle if you cut a circular groove in the underside of the cap screw with two lead out port for the arms. This would also make the keep screw head seat lower.

This would be quite an easy spring to duplicate with piano wire.

You wouldn't even need to make the choke after the cap screw circle if you cut a circular groove in the underside of the cap screw with two lead out port for the arms. This would also make the keep screw head seat lower.

Brokenlaig

36 Cal.

- Joined

- Jan 17, 2005

- Messages

- 97

- Reaction score

- 0

My Lyman 1851 Navy came with this spring already installed in it. I like it.Solitary Cyclist said:

I have to be honest, I didn't notice a significant difference with my Navy. The reason for fitting it was I noticed a flaw in the original spring. It had cracked in the centre and was only being held together by the pressure of the screw!

I ordered a wire spring from Wolff a few days ago, and got it yesterday. It fit perfectly in my Uberti M1860. It does seem like it made the action smoother, and you're right, I don't really feel any change in trigger pull. It's a neat modification that should last a lot longer than the original flat spring.

Thanks for all the explanations, M.D. Now that I've seen the spring in person, I don't think I could make my own. But at 6 bucks, the manufactured spring isn't too bad on the wallet.

Thanks for all the explanations, M.D. Now that I've seen the spring in person, I don't think I could make my own. But at 6 bucks, the manufactured spring isn't too bad on the wallet.