Sorry to hear that. I'm also glad you got it out so easily. Some folks aren't as lucky.

I'm not familure with the Kobalt name so I can't comment on it but your comments about it breaking like porcelain is a good description of how all taps break.

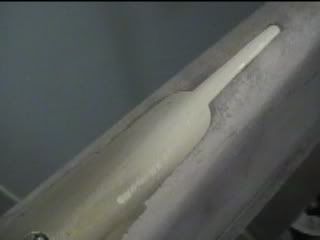

They are VERY hard and because of this, they break very easily.

I am sure you already know this however for those to whom making threads is a new adventure let me say the following:

I'm not sure what you were using to lubricate the tap with and I'm not sure how often and how much you were backing the tap out but here's ole Zonies take on tapping steel.

The tap absolutly must be lubed, and IMO, motor oil will not do the job.

I use a sulphated "thread cutting oil" that is available where ever they sell taps and dies.

I know there is another lard based oil that works well, but I forgot the name of it. Some of the other members have mentioned it by name before.

When starting the tap, keep it aligned with the tap drilled hole and give a steady downward pressure while carefully turning it.

If the tap starts crooked, do not push on it to straighten it back up. Back it out and try starting it straight.

When screwing the tap in, do not go over 3/4 of a turn without backing the tap back at least 1/3 of a turn. This "breaks" the chip and keeps it from binding the tap in the hole.

I go about 3/4 turn

or until the tap shows some real resistance

whichever comes first. Then I back it out 1/2 turn, advance it back to where it was and then go another 1/2 to 3/4 turn.

I repeat this until the tap shows little or no resistance.

So far, I haven't had the misfortune of breaking a tap in several years now (knock on wood :grin: )

Zonie