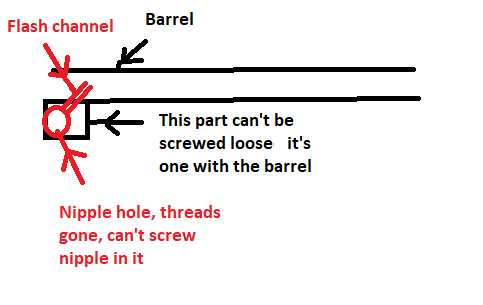

I've got a percussion rifle with a touch hole behind the nipple being about 5/64 or 3/32.

The nipple threads are gone so i would have to drill and tap a new nipple hole.

The question is if i place a 1/16 nipple in that gun and fire it, will there be a chamber between the nipple and the touch hole that builds up enough pressure to blow the nipple out of the gun?

Or will the nipple keep pressure inside the barrel as a bottle neck?

I'm not sure how i would fix the touch hole going into the barrel behind the nipple or if it's fine like that.

Sadly i have no pictures atm but the measurements are correct.

Any ideas suggestions would be welcome ty

The nipple threads are gone so i would have to drill and tap a new nipple hole.

The question is if i place a 1/16 nipple in that gun and fire it, will there be a chamber between the nipple and the touch hole that builds up enough pressure to blow the nipple out of the gun?

Or will the nipple keep pressure inside the barrel as a bottle neck?

I'm not sure how i would fix the touch hole going into the barrel behind the nipple or if it's fine like that.

Sadly i have no pictures atm but the measurements are correct.

Any ideas suggestions would be welcome ty