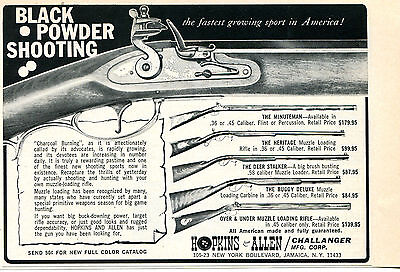

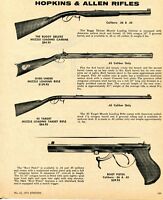

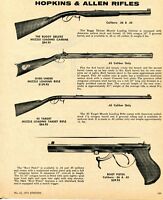

Andy, found these old advertisements.

I think when I get the stock shaped and sanded it's going to have some pretty nice figure in it.

I think when I get the stock shaped and sanded it's going to have some pretty nice figure in it.I took at least 3/16th of an inch off the bottom of the fore end and 1/8 off both sides removing those completely, mine were really thin. I left the nose cap on.Thanks, kje54 I checked out numrich wasn't much there I could use so there be a lot of handmade parts to get this rifle working. I looked at the lock plate thinking that I could at least start with a plate that fits but wow it was a rusty mess. Whatever kind of lock I use it will need to be really small I pulled a lock from my Pedersoli pistol and it almost fits.

Here are a few photos of the stock you can see where they used the glue but no screws. Actually,View attachment 70459 I think when I get the stock shaped and sanded it's going to have some pretty nice figure in it.

That's coming out nicely. I've got a shopping cart started at "Muzzleloaders Builders Supply" These are the thimble and pipes I'll be using, in addition, I'm ordering 6 silver oval plates to replace the brass one. The barrel is already set up for the locations of the pins so I'm pretty much stuck with that. Have you decided what you intend to do with the side plate? I ordered a piece of silver plate and figure I'll just make my own.I took at least 3/16th of an inch off the bottom of the fore end and 1/8 off both sides removing those completely, mine were really thin. I left the nose cap on.

View attachment 70465

View attachment 70466

Mine came completed, I just took it apart and started modifying the stock where I could so I have all the parts. The one thing I'm debating is completely redoing the patchbox, getting rid of the "brass blob", "paint spill" they called a cover.......... The challenge is I would have to construct one myself and it would take up most of the right side of the butt and I've never done one.That's coming out nicely. I've got a shopping cart started at "Muzzleloaders Builders Supply" These are the thimble and pipes I'll be using, in addition, I'm ordering 6 silver oval plates to replace the brass one. The barrel is already set up for the locations of the pins so I'm pretty much stuck with that. Have you decided what you intend to do with the side plate? I ordered a piece of silver plate and figure I'll just make my own.

I'll probably use some of the silver plate to make my own patch box but I'm not going to change the design that's already inletted. My biggest concern right now is finding a lock that will fit, if I can't find one I'm really not looking forward to building one from scratch., the rest of the furniture I can deal with. I'll most likely put a set of Davis set triggers in it rather then the single trigger that these guns came with.Mine came completed, I just took it apart and started modifying the stock where I could so I have all the parts. The one thing I'm debating is completely redoing the patchbox, getting rid of the "brass blob", "paint spill" they called a cover.......... The challenge is I would have to construct one myself and it would take up most of the right side of the butt and I've never done one.

Save your shavings and saw dust, if you can get a lock that is close you can always fill any gaps that are left.I'll probably use some of the silver plate to make my own patch box but I'm not going to change the design that's already inletted. My biggest concern right now is finding a lock that will fit, if I can't find one I'm really not looking forward to building one from scratch., the rest of the furniture I can deal with. I'll most likely put a set of Davis set triggers in it rather then the single trigger that these guns came with.

After doing some research this stock and barrel could be 50 years old.

I can't see the stock well enough in your photos to tell much about the wood but the one I have is not birch. Birch has near no figure and basically just a straight grained wood.I'm also considering using tannic acid & aqua fortis on my stock but not sure how that would work on birch. I tried the aqua fortis on a small area (since sanded down) and it came out a reddish brown. The tannic acid is to make the grain lines pop. I'd like to see one that is already done first, if it doesn't work that's a LOT of sanding to get it back down to bare wood.........

Not all birch, some speicies have a nice grain and can be mistaken for maple. My primary reason for thinking birch is even back then maple was expensive and H&As were inexpensive guns.I can't see the stock well enough in your photos to tell much about the wood but the one I have is not birch. Birch has near no figure and basically just a straight grained wood.

True any wood can have figure in a crouch or root, but some of the early H&A weren't all that cheap. Try a search here on the forum and there are a lot of post showing H&As costing more then Thompsons and Lyman's back in the late 60s and 70s.Not all birch, some speicies have a nice grain and can be mistaken for maple. My primary reason for thinking birch is even back then maple was expensive and H&As were inexpensive guns.

Then maybe it is maple.True any wood can have figure in a crouch or root, but some of the early H&A weren't all that cheap. Try a search here on the forum and there are a lot of post showing H&As costing more then Thompsons and Lyman's back in the late 60s and 70s.

BTW, the factory patchbox cover on the Minuteman is really thin, flimsy brass, maybe .010". What thickness silver plate will you be using? I need to know so I know what thickness brass plate to buy.I'll probably use some of the silver plate to make my own patch box but I'm not going to change the design that's already inletted. My biggest concern right now is finding a lock that will fit, if I can't find one I'm really not looking forward to building one from scratch., the rest of the furniture I can deal with. I'll most likely put a set of Davis set triggers in it rather then the single trigger that these guns came with.

After doing some research this stock and barrel could be 50 years old.

The silver plate comes in several thicknesses I bought .062 which is 1/8 thick. You probably could get by with a thinner piece but I'll be using it for the side plate also so it needs to be a little thicker.BTW, the factory patchbox cover on the Minuteman is really thin, flimsy brass, maybe .010". What thickness silver plate will you be using? I need to know so I know what thickness brass plate to buy.

I was thinking maybe .040" brass. Many call the patchbox the "paint spill", I call it the "brass blob".The silver plate comes in several thicknesses I bought .062 which is 1/8 thick. You probably could get by with a thinner piece but I'll be using it for the side plate also so it needs to be a little thicker.

Is your patchbox the hourglass shape or the longer more elaborate. The one on mine is the hourglass type. I have never used one of the cap or patch boxes on any of my rifles and I'm seriously considering just cutting a piece of sheet to fit and engraving it like an inlay. I just ordered most of what I'll need to complete the build with the exception of the lock, best guess I'll have about 450 in the rifle when finished.

Certainly isn't the prettiest patchbox I've ever seen. Maybe if it had some engraving on it, it wouldn't look so blobbish. I think .040 would be thick enough for your needs. I just measured the toe plate on the one I got and it's .050 even though I won't be using it. The stock in your photo I think is a lower grade of maple so the agua fortis should be fine.I was thinking maybe .040" brass. Many call the patchbox the "paint spill", I call it the "brass blob".

I saw a reference a while back to "burning" curl onto straight grain stocks using wire and a torch. Like the idea but have no idea how to go about it.Certainly isn't the prettiest patchbox I've ever seen. Maybe if it had some engraving on it, it wouldn't look so blobbish. I think .040 would be thick enough for your needs. I just measured the toe plate on the one I got and it's .050 even though I won't be using it. The stock in your photo I think is a lower grade of maple so the agua fortis should be fine.

I've burned curl in many a hawk haft and ramrod but never tried it with wire or on a stock. I wouldn't consider the stock I have to be highly figure maybe just a bit more than yours, here's a photo of mine in the comb area just wetted with water, and this stock hasn't even been started to shape or sand yet.I saw a reference a while back to "burning" curl onto straight grain stocks using wire and a torch. Like the idea but have no idea how to go about it.

Yeah, I hit mine with water and I think I see really faint curl lines.I've burned curl in many a hawk haft and ramrod but never tried it with wire or on a stock. I wouldn't consider the stock I have to be highly figure maybe just a bit more than yours, here's a photo of mine in the comb area just wetted with water, and this stock hasn't even been started to shape or sand yet.

Enter your email address to join: