- Joined

- Jan 30, 2014

- Messages

- 799

- Reaction score

- 15

I am building an muzzleloader with iron furniture. How is it to engrave steel versus brass.

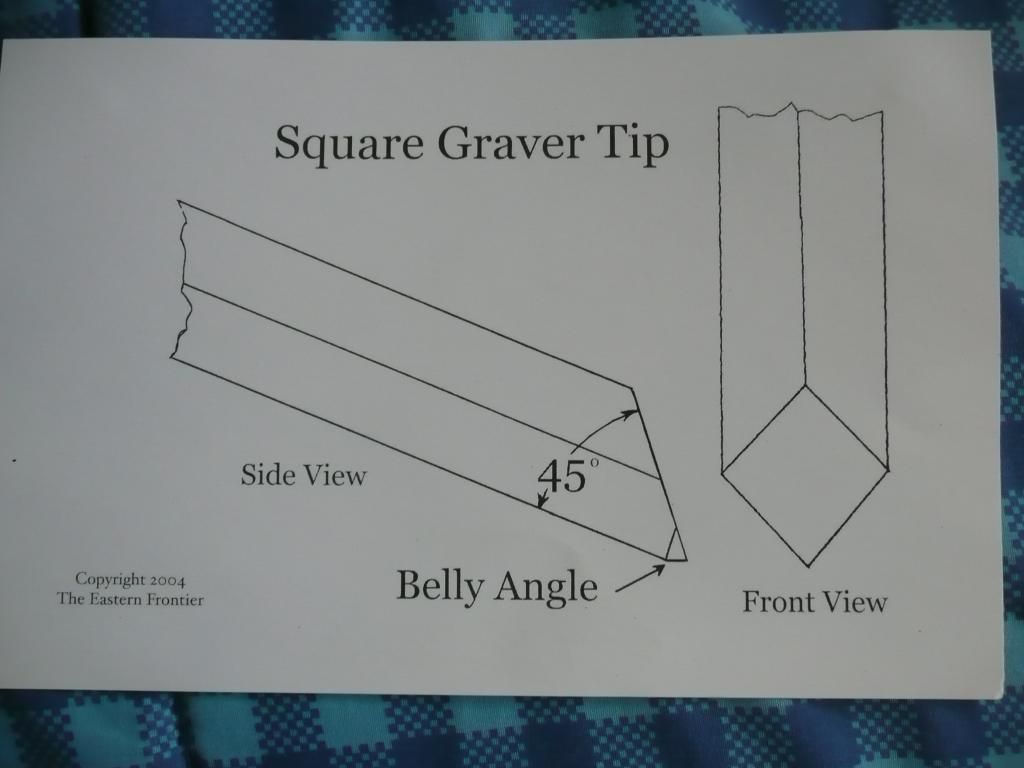

I am a bit lost what engraving tools to buy. I am making pretty much straight lines just to add a bit more detail. It'll kind of look like this.

------------------

//////////////////

------------------

If I can make the trigger ends look like that OK. I may make a pin stripe like outline around the lock plate. The width and depth of the engraving will more or less be as thick and deep as the lines of the letters I am typing.

The longer horizontal line I will make with a jewelers file. The angled short lines is where the engraving tool will come into play.

Should I pass it all together and wait until I build a brass rifle to start engraving.

Also, can I build the rifle, brown the metal parts, and then go back and engrave a year or two later once I start building the skill on other things.

I am a bit lost what engraving tools to buy. I am making pretty much straight lines just to add a bit more detail. It'll kind of look like this.

------------------

//////////////////

------------------

If I can make the trigger ends look like that OK. I may make a pin stripe like outline around the lock plate. The width and depth of the engraving will more or less be as thick and deep as the lines of the letters I am typing.

The longer horizontal line I will make with a jewelers file. The angled short lines is where the engraving tool will come into play.

Should I pass it all together and wait until I build a brass rifle to start engraving.

Also, can I build the rifle, brown the metal parts, and then go back and engrave a year or two later once I start building the skill on other things.