OK here goes I have been there and done that! DON'T DO IT unless for some reason you have to!

I my case I dry balled with a .495

ball.In my .50cal. Why is that unique you ask because I normally use a .490 ball.

While working up a load I decided to shoot a .495 ball with the same patch I had been using with the .490. The first one went down the barrel with good lube and a hand over hand technique. Not to say it went down easy but it went down. Now here is the part that I think got me into trouble.

I have a habit of when I bottom with my ball I usually will bump the ball with the rod., three times lightly. Not that I am OCD but just a habit, that way I am sure in my mind that the ball is fully seated on the powder.

Well since the first load went off with out a hitch I decided to try the load again.Only this time as I tapped the ball lightly I turned to see the powder still sitting in the measure. I think it swelled the ball enough to make it really tight! At that time

I was new in the BP game and did not realize the importance of having a rod marked for bottoming on a load mark!

After I dry balled I tried to use a ball puller to pull the ball in the field it was to no avail, because I stripped the center out of the ball (didn't know this for sure till later)and still had could not pull the ball.

After that I tried blowing it out, and pumping it out with grease but due the center being ripped out of the ball I was unable to move the ball.

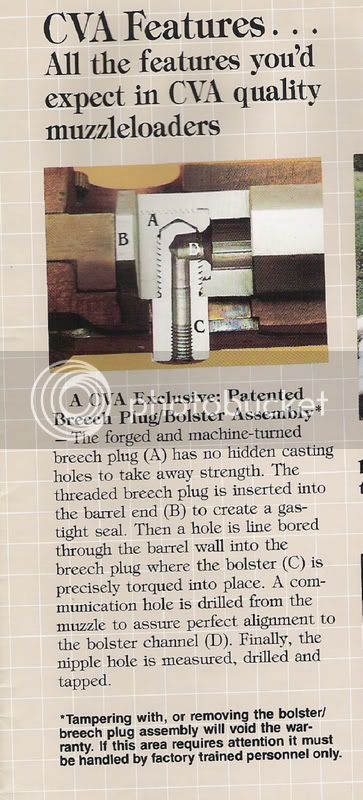

Not knowing what I was getting into I pulled the drum so I could remove the breech plug. I actually drove that dryball out of the barrel with a hammer and a long oak dowel. That is the last .495 ball I tried.

I once posted a thread about this but I can't remember the name of it anymore and don't know for sure if you could even pull it up.

I used a pair of vice grips to pull the drum and of course it was toast.

You can buy a CVA replacement but when it is pre- drilled for the nipple it probably won't line up. To remedy this I use a copper washer under it. Sort of a crush washer.

That served me for quite a while. Then I went to the range and I started having trouble, with misfires. The first time it happened I thought it was caps of perhaps I hadn't cleaned the gun properly. Took it home and made sure I cleaned the rifle well, and bought a brand new tin of caps!

The next trip to the range I started having trouble with misfires again. This time I caught it the drum had rotated just enough to allow for misalignment between the hammer and the nipple.

OK it was time to do something about this. I ordered the CVA replacement that has no hole drilled for the nipple. After repeated threading in and backing out to touch the back of the drum with a file to make sure I got a proper seating I then took the kit I had ordered from TOW to drill and tap the new drum to the proper place for a new nipple. The measuring for getting that right is tedious and I suppose a little luck don't hurt at all either.

I have some pics if I haven't gotten rid of all of them. Right now I can't get my Photobucket account to open for some reason but, I will try again later and if I still have the pictures I will post them. I also have pics of a wrench I made to remove any CVA or Traditions drum with out hurting it!

In short don't remove the drum unless absolutely necessary and if you do be prepared. Also if you pull the breech plug make sure to index it before removal!