mikemeteor

45 Cal.

- Joined

- Nov 16, 2008

- Messages

- 660

- Reaction score

- 3

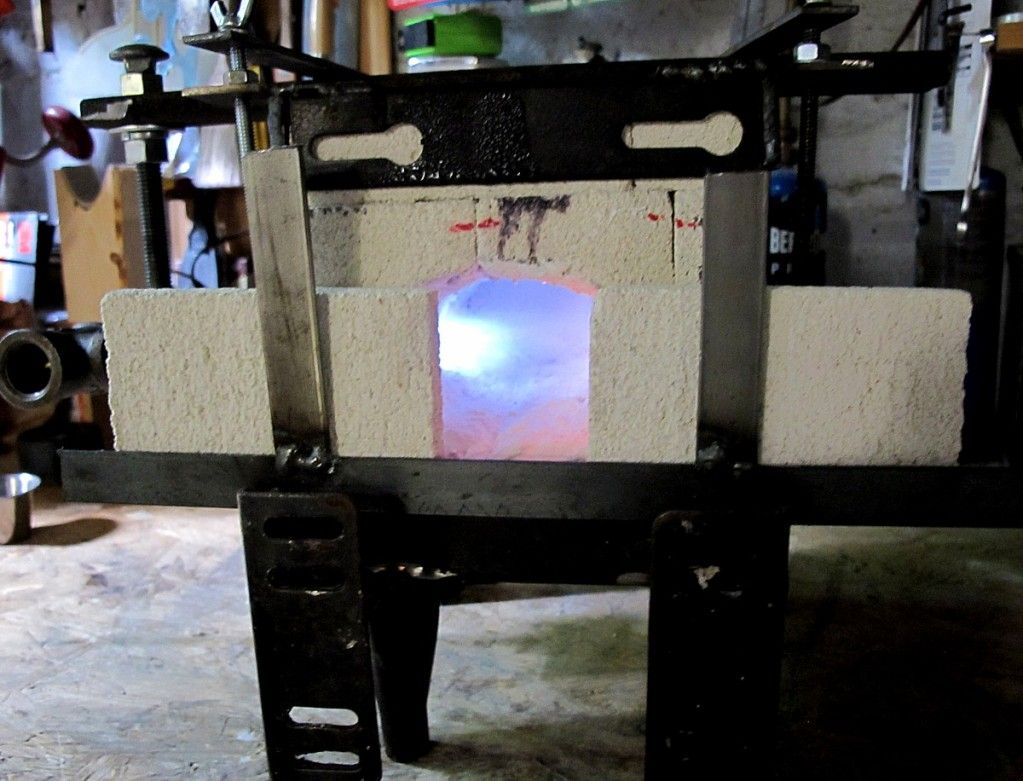

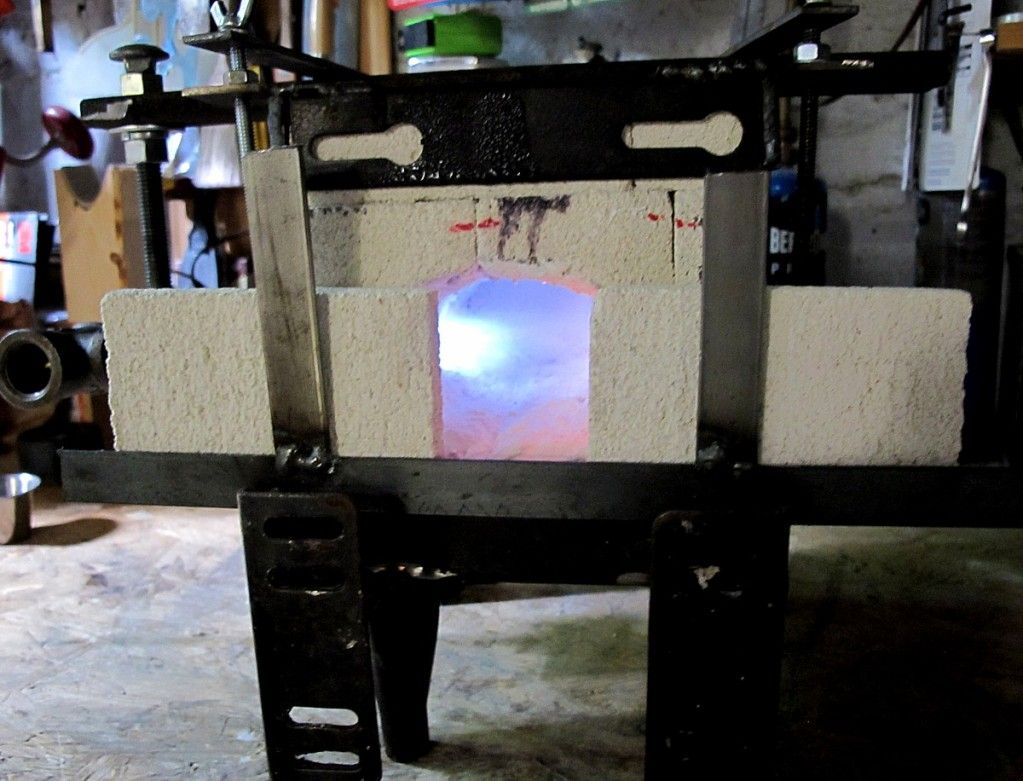

Finished up my propane mini-forge this weekend.

The soft firebrick is nice, but the guidance to coat it with Plistix seemed to make a big efficiency difference, altho I don't have a pyrometer yet.

The uncoated firebrick would get red hot(top pic).

The Plistix seems to not absorb heat near as much - at least it doesn't change color as fast(bottom pic). Added slider front doors.

Hope to beat out some small gouges from O-1 tool steel, and try forging a trigger guard eventually.

Whole thing was less than $100.

/mike

Soft firebrick only:

Lined with Plistix

Final design:

The soft firebrick is nice, but the guidance to coat it with Plistix seemed to make a big efficiency difference, altho I don't have a pyrometer yet.

The uncoated firebrick would get red hot(top pic).

The Plistix seems to not absorb heat near as much - at least it doesn't change color as fast(bottom pic). Added slider front doors.

Hope to beat out some small gouges from O-1 tool steel, and try forging a trigger guard eventually.

Whole thing was less than $100.

/mike

Soft firebrick only:

Lined with Plistix

Final design: