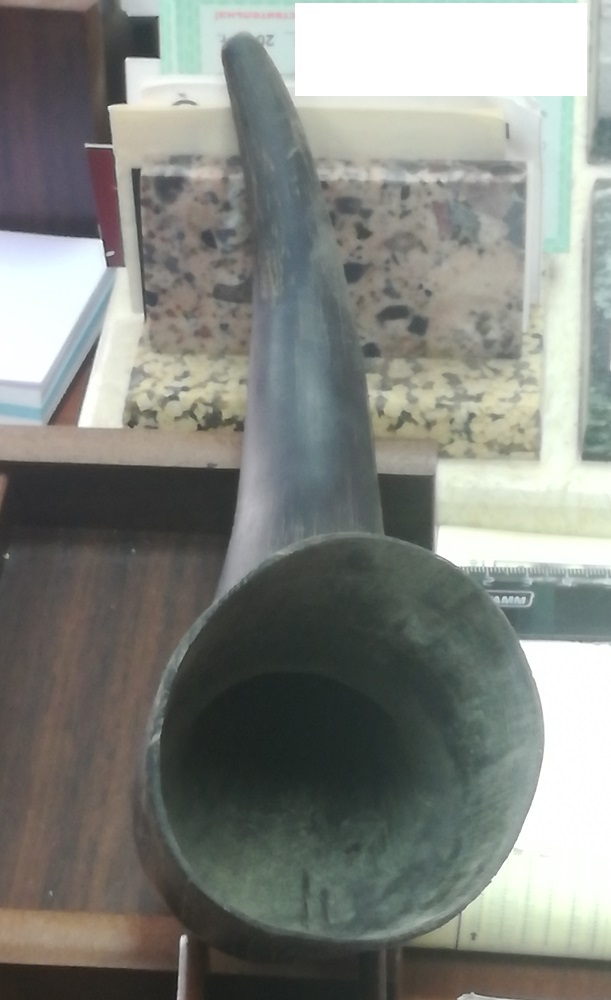

I just looked up this post . My birthplace was Sheffield England it wasn't just noted for steel it had a Horn industry long before the metal Flasks from such firms a Jas Dixon , Sykes , Hawksley ect .I often purchased horns & stag from a horn scale cutter firm .Scarlett & Whiteing on Rockingham Street , long gone but they didn't boil horn to flatten it they heated it till it was about melted then pressed it in a fly press or book press . When apon on cooling the horn stayed flat .If you just boil it , it retains a' memory' and will try to go back to its former state but when' cooked' it will never revert.

Stink the place out but not harm full .Horner's shops, work shops had rows of leg vices and moulds so you could quickly place a hot slab the size to press say a apparently carved butt plate ,razor / knife scale and the horn effectivly was like plastic. once cooled it stayed with its shape & design horn caps for shotguns all kinds of items now made of plastic the workers constantly placing and tightening vices while others released the cooled of items .when all the fash could be trimmed off ready for sale so numerous was this trade There was a pub called' The Pressers Arms ' Might still be.( But many pubs latterly became Day care centers !.) I have made horn butt plates for wheellocks there still flat as a pancake 35 years later . Your basic plan is sound but boiling does not do as good a horn flask as heating will .Roland Cadle noted Pennsylvania Horner gave me two flatted horns , both I made into flasks Scots style .

Regards Rudyard