Nice. Looks like the perfect 'carrying' or 'user' knife for woods and camp. :thumbsup:

-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

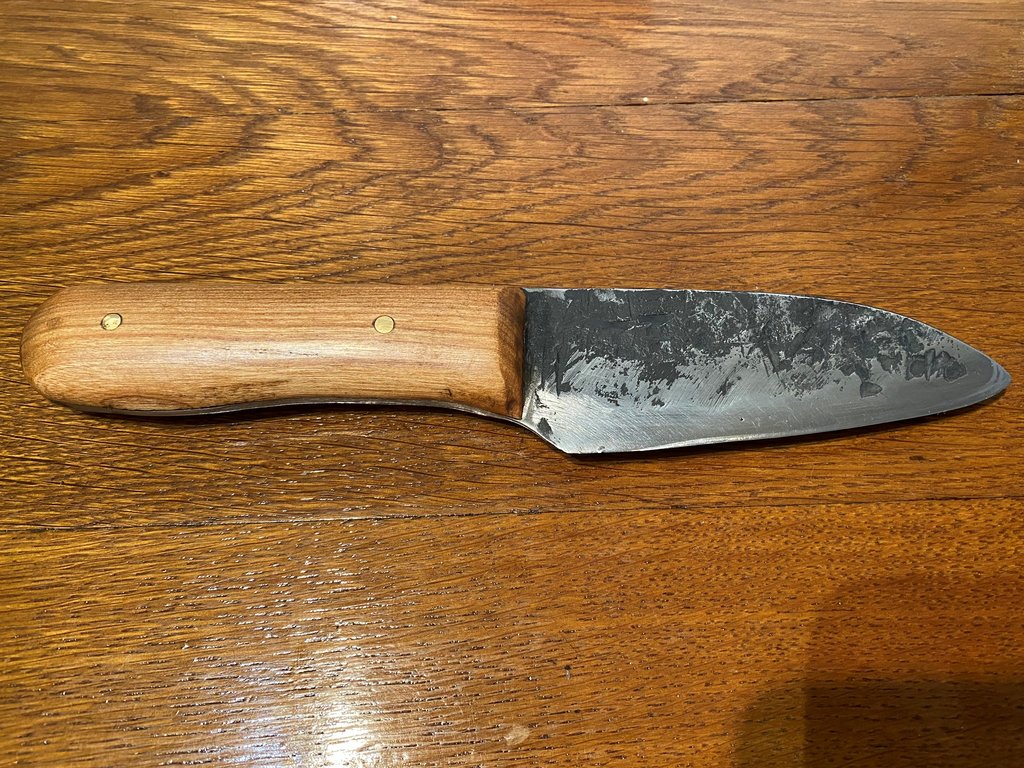

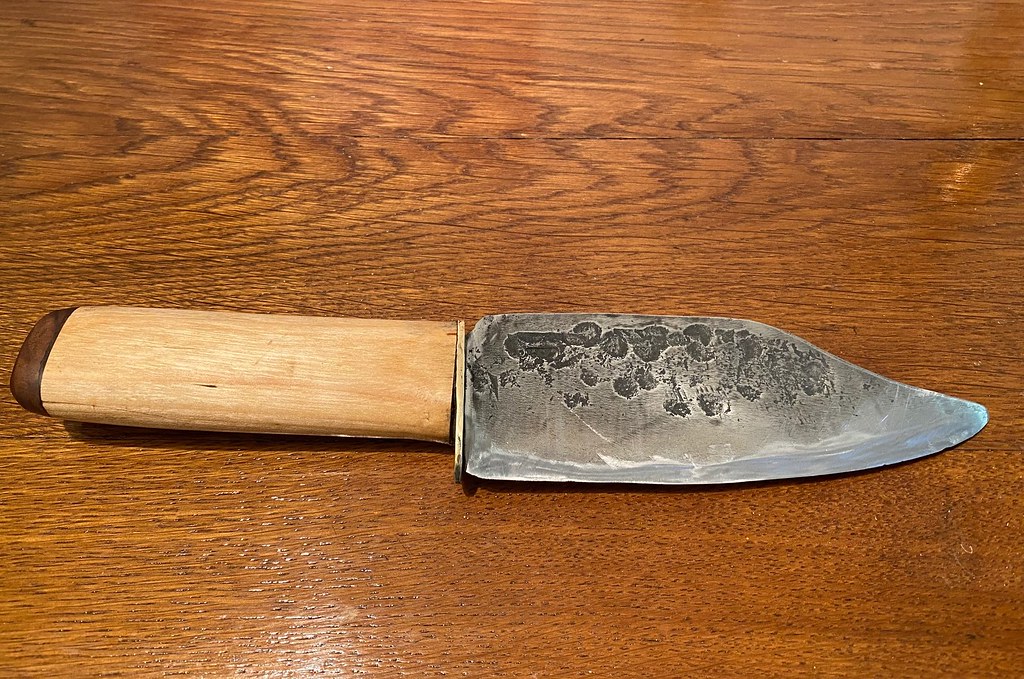

one more from scrapforging

- Thread starter cal.43

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

https://i.postimg.cc/C5T3823v/IMG-2810-2.jpg

https://i.postimg.cc/NfGNnYk6/IMG-E0047-2.jpg

two more,

sorry the other images are gone.

https://i.postimg.cc/NfGNnYk6/IMG-E0047-2.jpg

two more,

sorry the other images are gone.

Knife by cal_43spanish, auf Flickr

Knife by cal_43spanish, auf Flickr more Knifes by cal_43spanish, auf Flickr

more Knifes by cal_43spanish, auf Flickr Knife & food by cal_43spanish, auf Flickr

Knife & food by cal_43spanish, auf Flickrhope this works

Your knives look extremely usable. Usable being the main word. Beauty is in the eye of the beholder and some of the camp and heavy used knives I own aren't pretty. Pretty don't count when you got to cut or chop something. My guns aren't necessarily pretty either but they work. Some people just like shiny polished stuff, I like used looking stuff. Keep up the good work.

Knifex sharp by cal_43spanish, auf Flickr

Knifex sharp by cal_43spanish, auf FlickrQuarantine boredom got a hold of me a week or so ago and I took a couple of days to make my boss a knife out of a piece of structural steel from the 120 year old building that the brewery is in. We had to remove a set of the exterior windows and portion of brick wall a while back to be able to crane in a 3,000 gallon tank into the second floor. Anyway I used a chunk from the steel that had held the 8 foot window panels in place, the building was designed to withstand the direct force of an F4 tornado so every piece of the structure is almost over engineered. I heated the steel to anneal it and rough shaped it with an angle grinder. Got out the hand files and gave it its final shape and set the edge angle. Then cleaned up the file marks on a belt sander before hand sanding it with 500 and 1000 grit and finished the polish with fingernail type emery boards. Heated and quenched to re-harden, a quick polish, and sharpened to razor sharp. Used some scrap walnut I had for the handles scales held in place with three brass wire pins. Turned out to be a nice little roach belly!

firestick

40 Cal

I like the profile. Is that a Devile Forge?

RoaringBull

40 Cal

I'd love to learn to forge but I'm just too dang lazy. Nice knives!

OK!! where is the CHEESE? that is all that is lacking. the photo makes me Hungary! it is all that is needed after a days hunt!!Knife by cal_43spanish, auf Flickr

more Knifes by cal_43spanish, auf Flickr

Knife & food by cal_43spanish, auf Flickr

hope this works

Similar threads

- Replies

- 1

- Views

- 97

- Replies

- 0

- Views

- 106

Knifex

Knifex