There have been a few posts on building new shop spaces lately on this, and a few other forums that I visit, so I thought I would show how I go about setting up a new space.

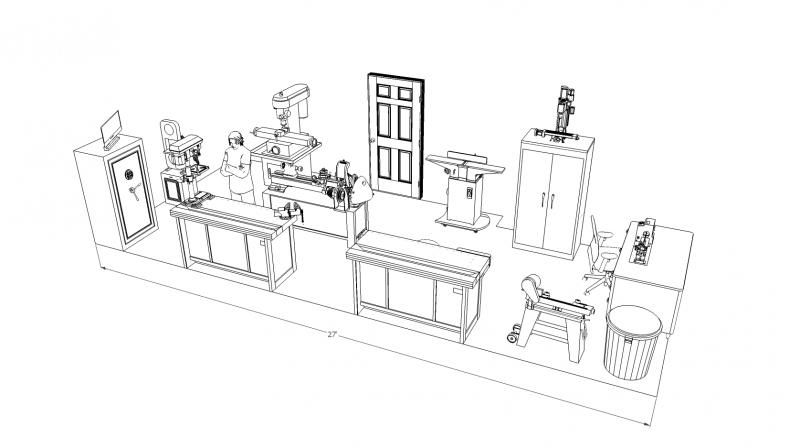

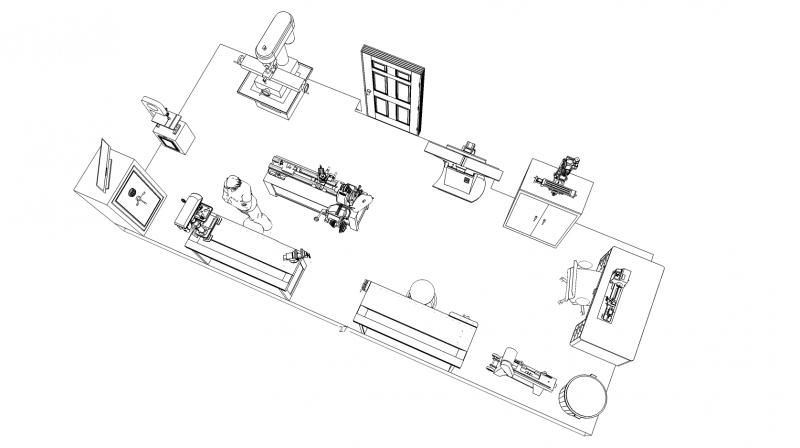

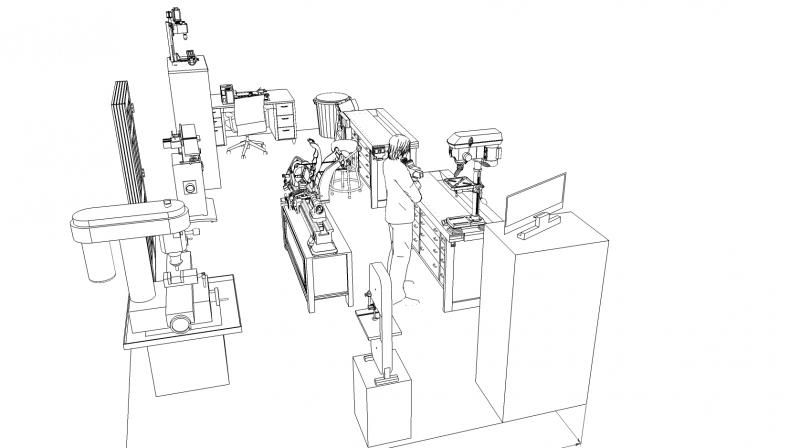

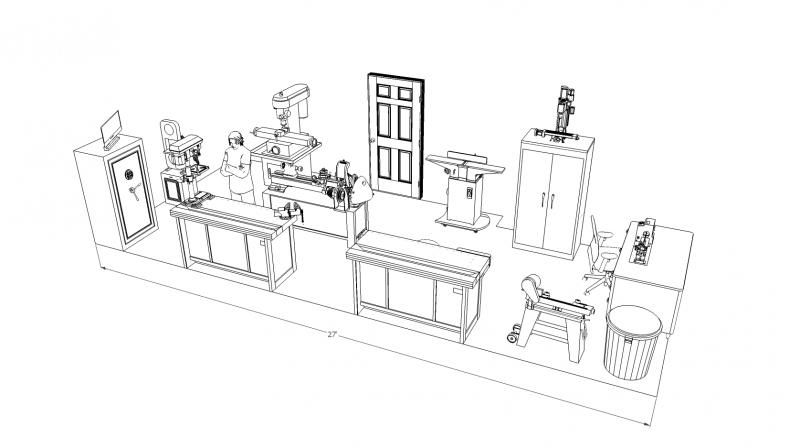

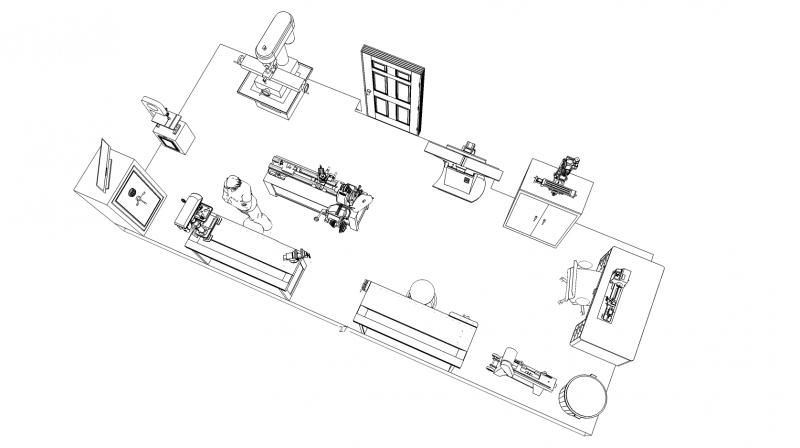

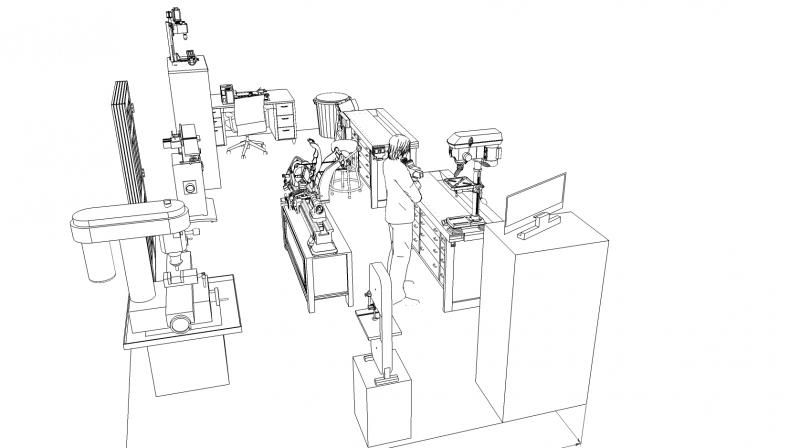

A basement renovation last summer provided me with a new shop space to replace my old cramped corners in a small spare bedroom. My new area is about 27' x 12'. Not huge, but definitely a step up from my previous quarters. One challenge that I now have is finding a way to fit the equipment that I have accumulated over the years, much of which was in storage because of space issues.

Since I like to plan everything before plunging in, I used SketchUp software to layout the new space. Most of the equipment that I had was already available in their free warehouse which has 3D CAD blocks, so about all I had to do was make some slight modifications to match the size of my machines/cabinets. In any event, it is much easier to visualize where things need to go and decide if I have enough room to work. Also makes it easy deciding where to run ceiling outlets and place lighting.

Incidentally, this is the same approach I used when remodeling the rest of the basement. Made it a lot easier to get approval from my wife before proceeding and really cut down the amount of work that needed to be changed later on.

A basement renovation last summer provided me with a new shop space to replace my old cramped corners in a small spare bedroom. My new area is about 27' x 12'. Not huge, but definitely a step up from my previous quarters. One challenge that I now have is finding a way to fit the equipment that I have accumulated over the years, much of which was in storage because of space issues.

Since I like to plan everything before plunging in, I used SketchUp software to layout the new space. Most of the equipment that I had was already available in their free warehouse which has 3D CAD blocks, so about all I had to do was make some slight modifications to match the size of my machines/cabinets. In any event, it is much easier to visualize where things need to go and decide if I have enough room to work. Also makes it easy deciding where to run ceiling outlets and place lighting.

Incidentally, this is the same approach I used when remodeling the rest of the basement. Made it a lot easier to get approval from my wife before proceeding and really cut down the amount of work that needed to be changed later on.