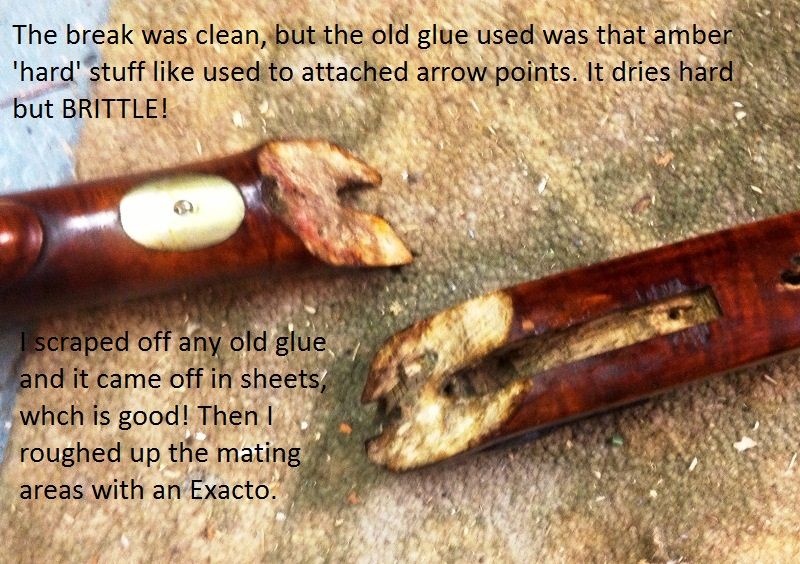

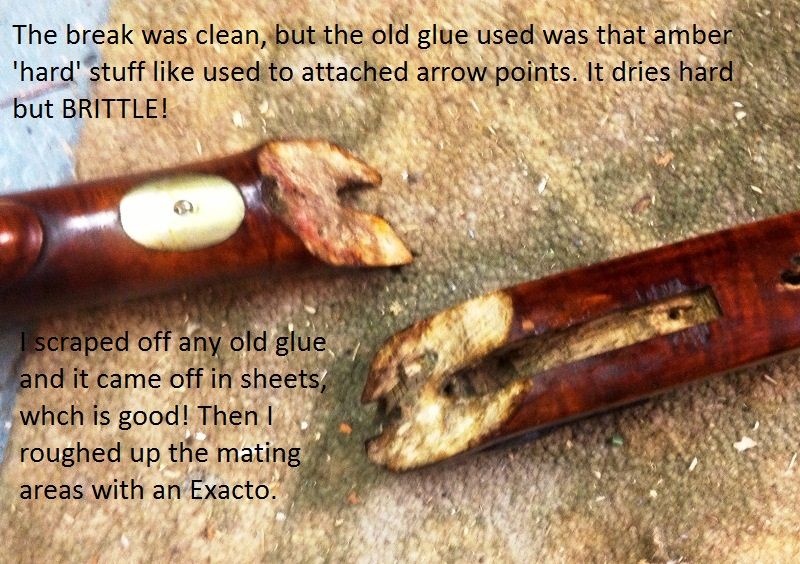

Long story short, but I had purchased a used 45-cal left-handed flintlock with a Douglas barrel on it, from a seller (on another forum) who had listed it with a “crack in the wrist”. Well when it arrived it was more than just a crack, it was a clean break right through. Even worse, someone had attempted a repair using that thick amber-colored glue like one might affix arrowpoints on with. Let’s just say I got $100 plus shipping charges back from the seller and I only have $200 into this rifle. To me, that’s worth it for a DIY project!

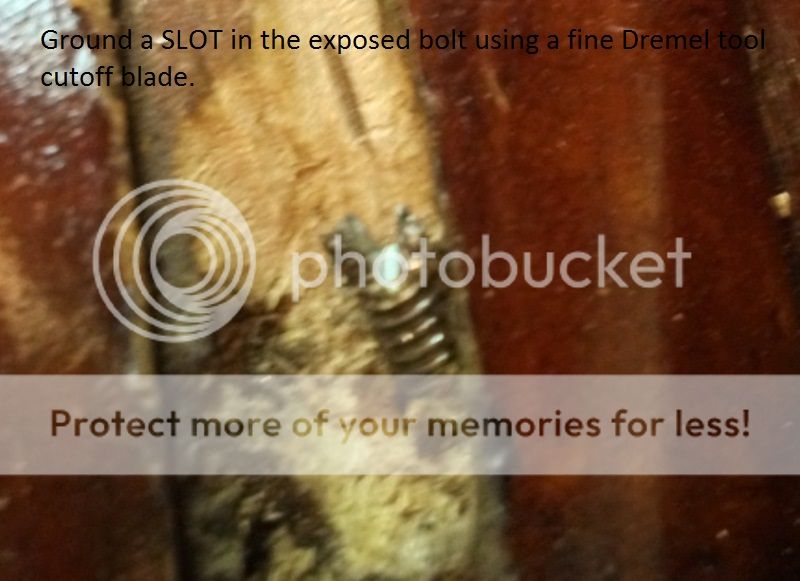

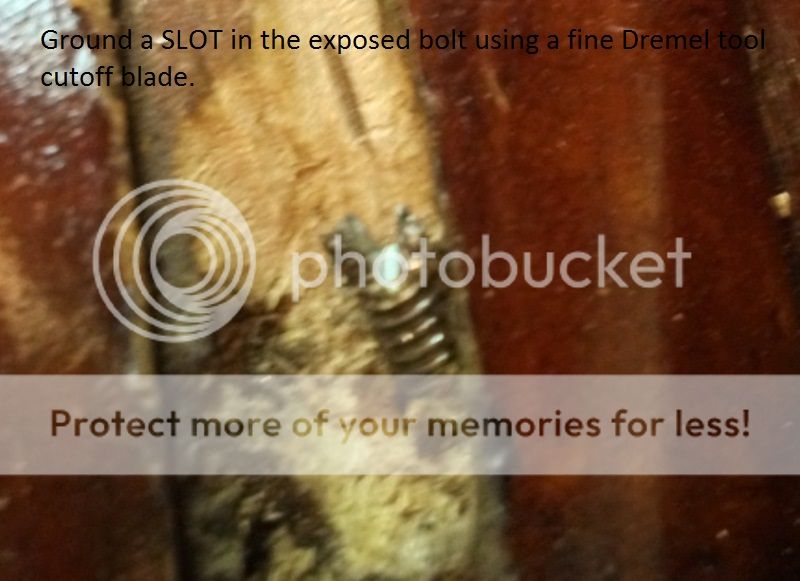

Fast forward to the other day and I got the old screw out that was holding it together. The break isn’t entirely clean, but I removed all of the old glue that I could and started to effect my repair.

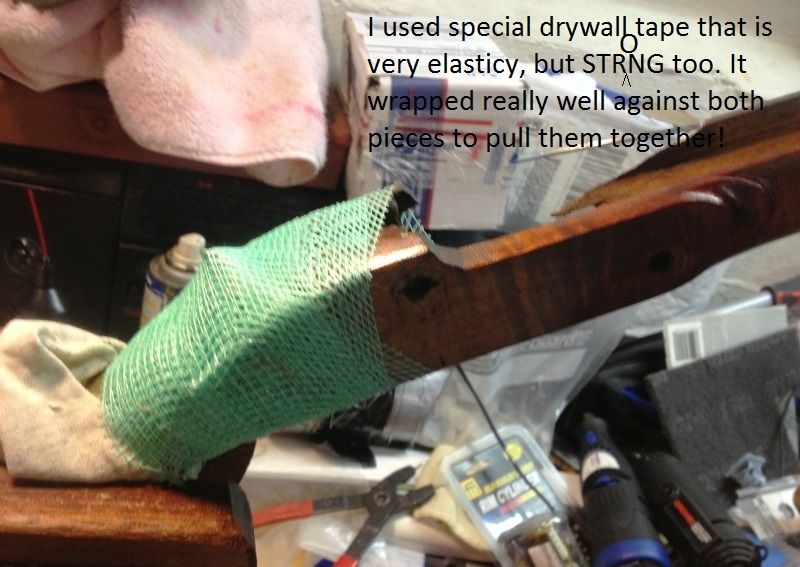

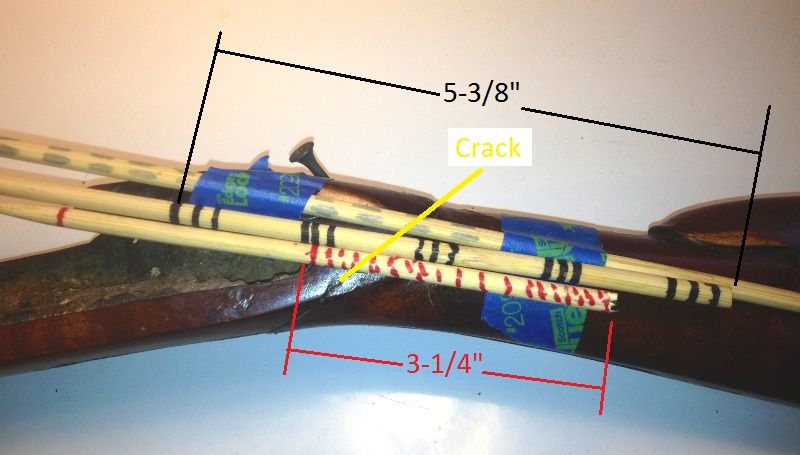

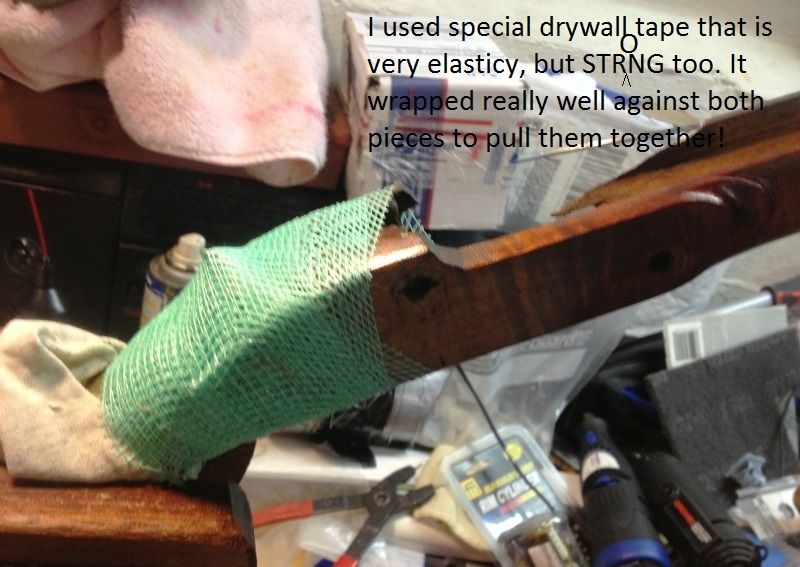

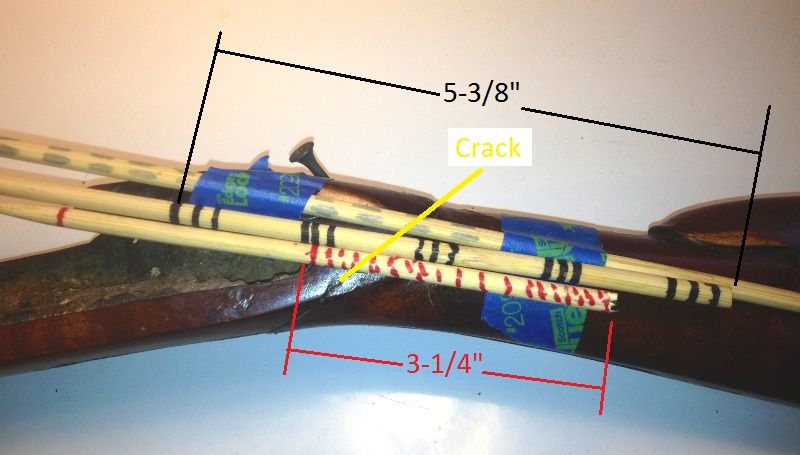

From the pictures, you can see that I drill two long holes angled back from the tang and lockplate (LH lock) areas, so they go through the forward end of the break and well past the break into the wrist area. With such long “blind holes” my plan is to use hollow graphite pieces (old broken rod sections) wrapped in fiberglass matting. The hollow tube will prevent any air hole from forming in the long blind holes, plus the tubing and matting are fully compatible, so there will be a full chemical and mechanical bond in the repair area.

The pictures show my plans. I also will strip the stock and re-finish it and thin out a few areas. If the break area cleans up well, I may just leave it with the break showing. Or I may try wrapping it with leather or brass like I have seen before.

Does anyone have any favorite photos of a repair area, with or without wrapping, on a longrifle that they would like to share? Thanks in advance! And comment away ”¦ with the good, bad, or the ugly ”¦ as my hope it to turn this ”˜pigs ear’ (no offense to pigs) into a sow’s purse ”¦ or at least a shootable MZL longrifle, for short $$ to boot!

Fast forward to the other day and I got the old screw out that was holding it together. The break isn’t entirely clean, but I removed all of the old glue that I could and started to effect my repair.

From the pictures, you can see that I drill two long holes angled back from the tang and lockplate (LH lock) areas, so they go through the forward end of the break and well past the break into the wrist area. With such long “blind holes” my plan is to use hollow graphite pieces (old broken rod sections) wrapped in fiberglass matting. The hollow tube will prevent any air hole from forming in the long blind holes, plus the tubing and matting are fully compatible, so there will be a full chemical and mechanical bond in the repair area.

The pictures show my plans. I also will strip the stock and re-finish it and thin out a few areas. If the break area cleans up well, I may just leave it with the break showing. Or I may try wrapping it with leather or brass like I have seen before.

Does anyone have any favorite photos of a repair area, with or without wrapping, on a longrifle that they would like to share? Thanks in advance! And comment away ”¦ with the good, bad, or the ugly ”¦ as my hope it to turn this ”˜pigs ear’ (no offense to pigs) into a sow’s purse ”¦ or at least a shootable MZL longrifle, for short $$ to boot!