Robin's little wheellock arrived today - thanks, Claypipe.

Here are some photos to hopefully get some discussion going.

An overall view with a pencil for scale - it's a teenie one, all right.

A view of the inside

A bottom view showing the messed up pan cover arm return spring - someone drove a screw into it.

The above shot also shows one of the things that need fixing - the end of the bridle should have a piece going down into the lockplate, for the main spring to stop against rather than the chain having to stop it.

And speaking of the chain - it's a tad longer than it needs to be.

The sears seem to work sorta OK, but it would be nice to be able to work on them - alas, they are riveted in.

Here's a shot of the inside end of the brass thingie. It's the button that's supposed to release the pan cover and let its spring (the one that got trashed by a screw) push it closed.

Here's a shot from the other direction, which also shows the break in the return spring (on the right). Note there is no bolster under the pan cover.

Here's the other end of the button, showing a slight interference with the dog-arm spring. The button really isn't practical on this tiny lock, anyway - not much room for a finger in there.

Another little issue is that the main spring is a bit too long. This shot shows where it is hitting the wheel shaft next to the lock plate.

The trigger is very odd. It slides.

Here's the inside

Here's a shot of the stock. Feels like pine.

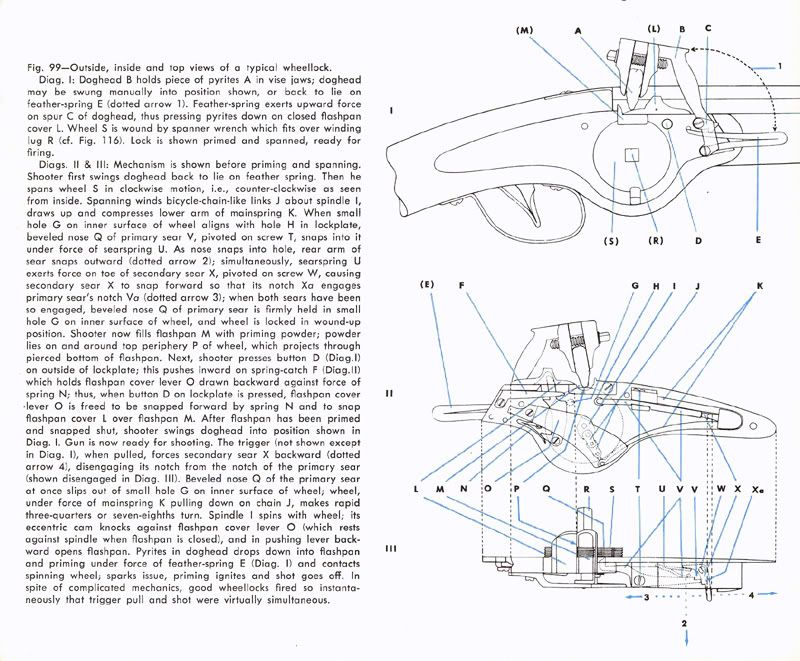

Interestingly, the diagram Tinker2 sent me is indeed for this very lock. It looks like the builder had only that diagram to work with. The diagram does not show the post at the end of the bridle to stop the spring, it doesn't show how the trigger is made, it doesn't show the bolster that is supposed to be under and supporting the pan cover - yup, the builder did a good job of following the diagram.

More later...

Here are some photos to hopefully get some discussion going.

An overall view with a pencil for scale - it's a teenie one, all right.

A view of the inside

A bottom view showing the messed up pan cover arm return spring - someone drove a screw into it.

The above shot also shows one of the things that need fixing - the end of the bridle should have a piece going down into the lockplate, for the main spring to stop against rather than the chain having to stop it.

And speaking of the chain - it's a tad longer than it needs to be.

The sears seem to work sorta OK, but it would be nice to be able to work on them - alas, they are riveted in.

Here's a shot of the inside end of the brass thingie. It's the button that's supposed to release the pan cover and let its spring (the one that got trashed by a screw) push it closed.

Here's a shot from the other direction, which also shows the break in the return spring (on the right). Note there is no bolster under the pan cover.

Here's the other end of the button, showing a slight interference with the dog-arm spring. The button really isn't practical on this tiny lock, anyway - not much room for a finger in there.

Another little issue is that the main spring is a bit too long. This shot shows where it is hitting the wheel shaft next to the lock plate.

The trigger is very odd. It slides.

Here's the inside

Here's a shot of the stock. Feels like pine.

Interestingly, the diagram Tinker2 sent me is indeed for this very lock. It looks like the builder had only that diagram to work with. The diagram does not show the post at the end of the bridle to stop the spring, it doesn't show how the trigger is made, it doesn't show the bolster that is supposed to be under and supporting the pan cover - yup, the builder did a good job of following the diagram.

More later...