- Joined

- May 6, 2014

- Messages

- 16,892

- Reaction score

- 15,309

Well said Gus.

I must admit, I have two more of these India LLPs – that makes three all together.

One is the one in my first post here in his thread.

The second one is really a piece of trash, - it was the first one I bought years ago, has a German proof, but is covered in a deeply brown varnish.

It turns out, after I removed the varnish, which took me four days(!!), the stock is about 40% woodfiller – so I stored it in my shop to maybe make something out of the parts (a COS Musket or so) when I do have the chance to get my hands on good a stock…

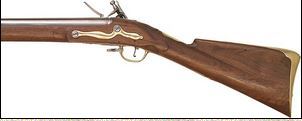

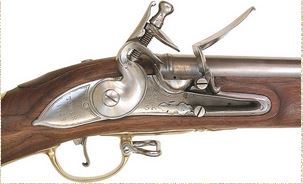

The third one is just on the way to my house. I found her on a website of a German dealer.

From what I can tell so far, the LLP has a single bridled lock (1730) and the stock is oiled just as the LLP from Loyalist Arms.

I bought it for very small money and it is already proofed by the German Proofhouse – so it is safe for both, blanks and live fireing.

I have some (rather poor) pics of the later one, and I gladly share them with you:

I will post some better picture, when I have it in my hands.

But as to what I can tell from those poor pics, ist got a wooden rammer, the lock is banana shaped and single bridled, aprons around the lock are looking a bit smaller than the ones on the Loyalist Arms LLP – but again, I can’t really tell without seeing the Bess...

EDIT:

I think you must understand, here in Germany, we do not have much things to choose from when it comes to guns.

We do not have TRS and/or TOW and if we try to order, they do not take PayPal plus the fact that gun parts could not be shipped outside US.

So the only options we have is either the (what ever it is) from Pedersoli, or any India made gun.

So if you like to have a 46" full size LLP - India made guns are your only choise.

I have been at the proofhouse to get the official test and proof on one of those India muskets that I have ordered for my brother. He and his men are reenacting the Ansbach-Bayreuth Troop of soldiers, send over to the AWI to fight for the British King.

Bad thing - since FEB this year, we have a new, stronger gun law in Germany. This also means new rules for the gun proof.

What they did was measureing the barrel, then they put 300 grain FF powder plus 2 patched round balls into the barrel and fired it from the musket 5 times!

They measured after each shot. Well the musket made it. Proofstamps on it tells you it is considered "Safe to shoot".

No cracks in the stock, no harms to the barrel – no harms to the breech plug - everything is fine.

Hey Ike,

Something I didn't ask before was do the Loyalist Muskets have a lug soldered to the barrel to support the front sling swivel?

Before anyone takes that as a dig, neither my old Pedersoli Carbine nor my more recent Pedersoli Musket has the bayonet lug installed at the factory.

The reason I ask is because I saw a lot of both Pedersoli and Miroku Muskets that were seriously chipped and some cracked in that area because they didn't have those lugs, in the hands of other reenactors. Now the funny thing is I have actually slung and used the sling as a "hasty sling" when shooting my carbine in live fire a lot and never got the chipped out area or cracks from the lug not being there. Most reenactors I'm familiar with never used their slings even to "sling arms," so I am a bit mystified how so many stocks got damaged there. Perhaps they did it by mistake when drilling the fore arm for the front sling swivel, but I don't know for sure. Yet, I have that on my "to do" list to add the lug to my Pedersoli Musket so the next owner doesn't have to worry about it.

Gus