So are you asking about using Acraglass to correct a mistake?

When it comes to "factory" kit guns, it has been my experience that these tend to be pretty much wood finishing and metal polishing projects. The barrel and the lock, trigger, and other parts come pretty close to pre-fitted..., with the brass sometimes needing polish. The most difficult factory kit that I've encountered was a vintage Jap Bess kit, still in the box, but no directions, and I had to locate and drill the holes for the ramrod thimbles, and polish the brass. So I don't think a factory kit will have you inletting anything at all...., and an Acraglass kit would be unneeded.

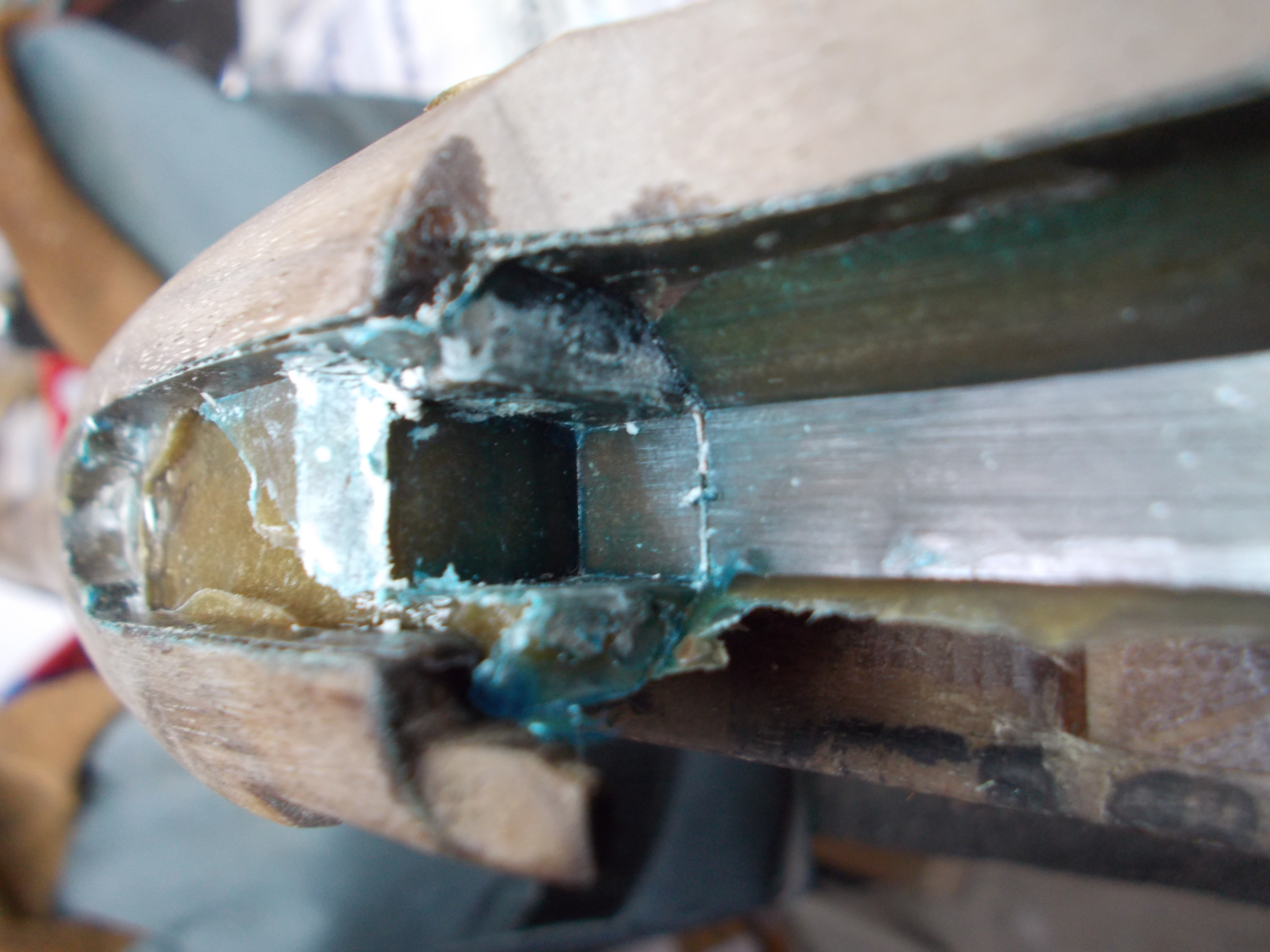

Now, it's good to have the kit on the shelf. I've seen factory kits and factory guns get some wicked cracks, and the stuff is good to stabilize those and even to bed the breech/tang area on some muskets, because if the factory has taken too much wood out from the breech, the recoil can cause problems with the wooden stock. The Acraglass bedding of the tang area and the tang bolt hole, seems to do a good job of displacing the recoil as it's taken by the stock, and avoid those problems.

LD