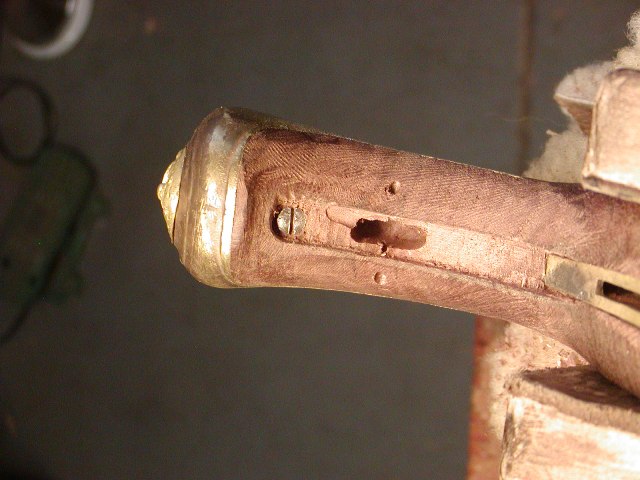

Got to inlay the sideplate and install the trigger today, with some more shaping around the butt cap. Slow going, but very enjoyable.

I found a great tutorial on You Tube of how to actually build this type of French Dragoon pistol. This should be very helpful!

Hey Dave, Yes, You Tube is like the information/misinformation buffet universe where you can choose what you like or don't, but it's all put out there. I couldn't know his aptitude in building this pistol historically correctly, because I am not certainly not qualified to say. but I think I did learn some things by watching him, which helps me.Hi Bob,

I am sorry but he doesn't know anything about building one of these pistols. As with so many You Tube videos they are by people with who rarely have much knowledge about historical details.

dave

Thats great- I am glad you enjoy this project. Hope I don't screw it all up somehow thoughI really enjoy your build posts! Step by step, with good illustrations.

Inspiring. Thanks! and Carry on!

PleaseThats great- I am glad you enjoy this project. Hope I don't screw it all up somehow though

Thank you Dave!Hi Bob,

Looking great! On page 252 of George Neuman's "Battle Weapons of the American Revolution" is a nice example of the pistol you are building.

dave

Enter your email address to join: