I will touch on the underlug part a bit:

IMHO, Best thing to do is get the dremmel out of the thought process & out of the building equation.... :shake: Every one I ever saw start with a dremmel ended up with disaster. :surrender:

That being said, I do use one at times, but it was a long time before I did & only on certain areas. The one to get has a 4' flex shaft with a tool head about the size of your index finger. One as such you can keep a hold on & control

much better than the ones with the tool head at the motor, and also buy Carbide bits for all you can for it as they will outlast the others 4 to 1.

Note: Barrel & Tang should be inlet into the stock & in proper placement of the to allow the vent liner to be in the correct place, in reference to the flashpan of the lock,

IF you are using a pre-inlet stock. On a pre-inlet stock that has the lock inlet started, it is Lock inlet first, then barrel second, then tang put on barrel & tang inlet third.

You don't need a jig for dovetails for the underlugs, ya just cut them with a hacksaw. I have done dozens upon dozens of them with no jig & never messed one up. First one took me over an hour, as I was so scared I would mess up. Now I do 4 of them in less than 20 min. :thumbsup:

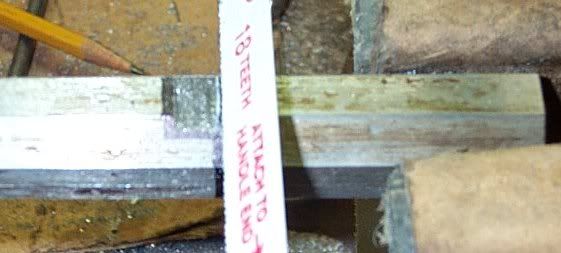

Here are some old photos I found doing one, can't find the one me filing the bottoms & edges of the dovetail, but this will give ya the idea. I have since found prefer a 24 tooth saw blade rather than the 18 tooth blade.

It is important you locate where they will go in reference to where your RR pipes as well, as it is a problem when you have a pipe & underlug in the same place, and also makes a weak spot in the forestock if the underlug & RR pipe are right against each other. (makes if fragile taking the barrel in & out of the forestock & subject to breakage of the forestock.

File the back side of the underlug sharp edge off, as you can't file a slot that sharp anyway. When finished, if it is a tad loose, don't fret. Just stake it in 4 places with a centerpunch. I usually stake all of mine regardless. Don't know why, they can't fall out anyway once they are in the barrel channel, I just like them snug.

Don't hoss them in too tight or you will just distort the underlug or dovetail slot or both & really don't need to be so tight it tears the underlug up.

I inlet the underlugs into the barrel channel & then I file the corners off a little as to keep from snagging my hand on them, as I will have that barrel in & out of the firestock dozens of times, and they will gouge your hand. I grind the sides of the dovetails flush with the barrel flat.

This is a ultra-slim 3 sided file with one side sanded down on a belt sander.

Maybe this will give you an idea where you are headed anyway. I am sure others do it differently, this is just what works for me.

:thumbsup:

Keith Lisle