I have a small booklet, A Brief History of Bullet Molds, by Codman Parkerson, 1974, and it has some interesting early molds.

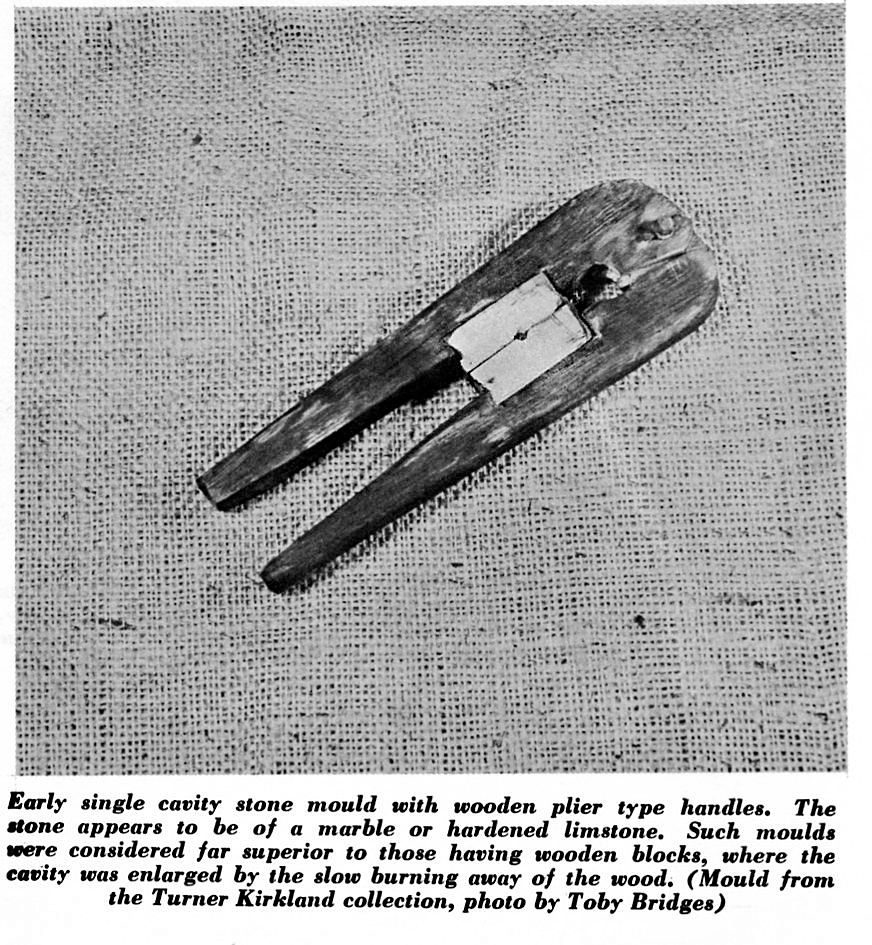

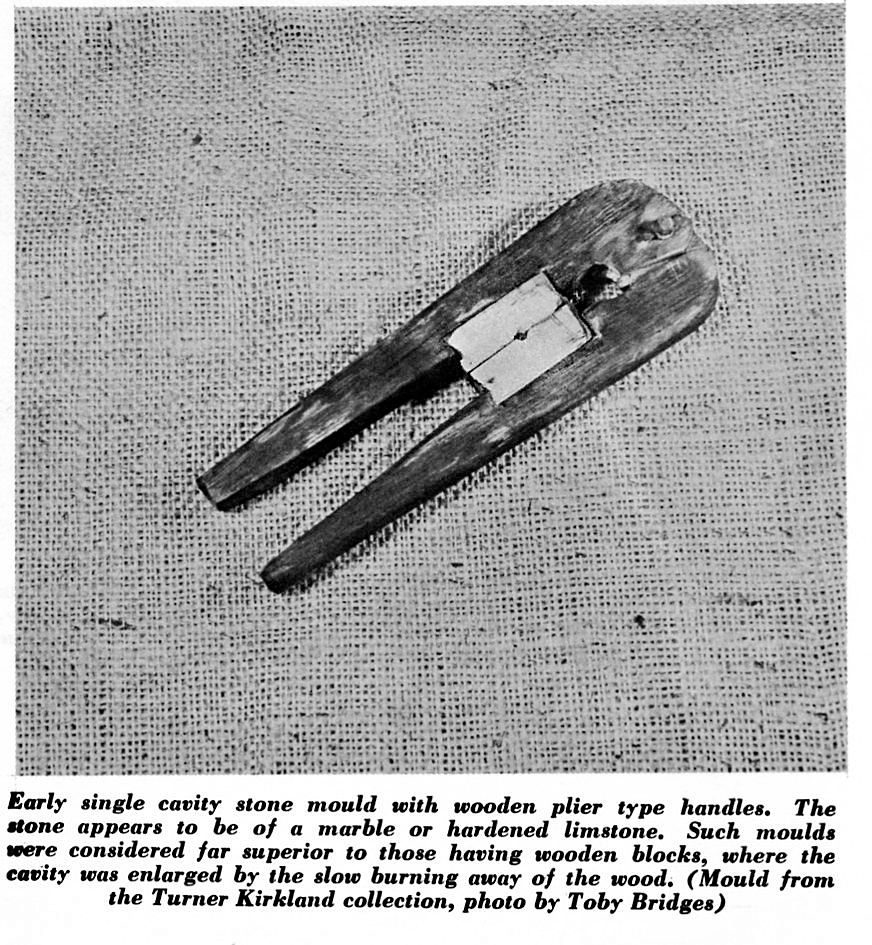

This one is made with stone blocks in a wooden handle. It’s not soapstone, but marble or limestone. Wonder how the caviries were cut.

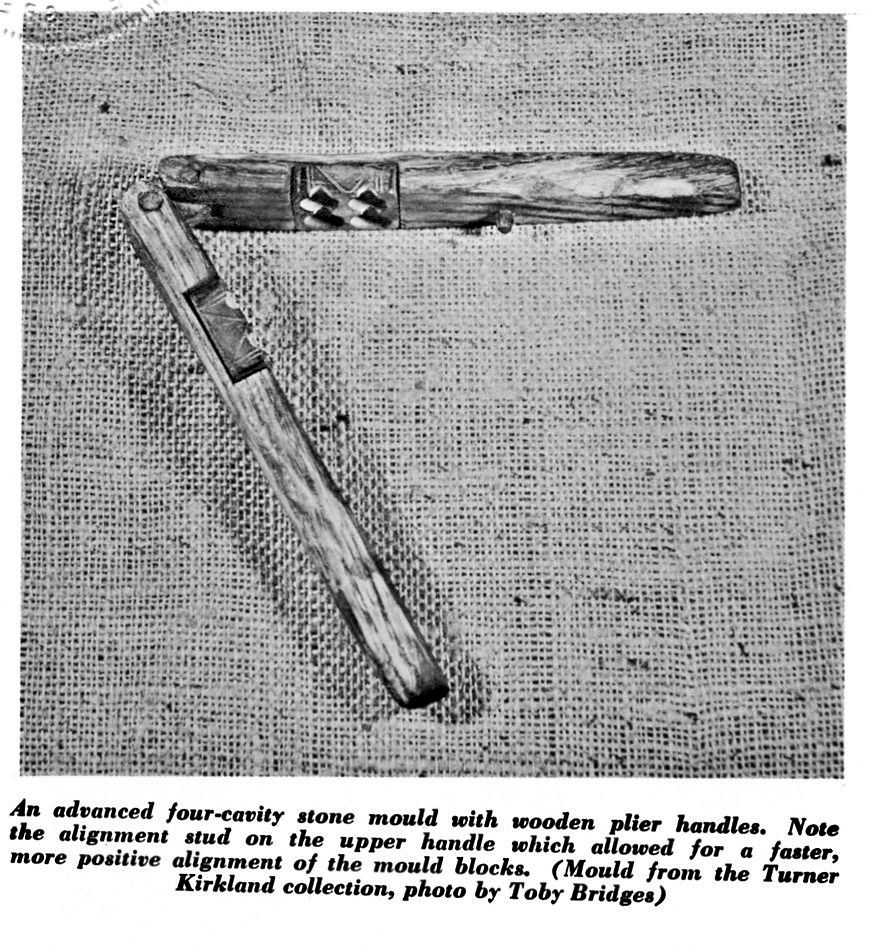

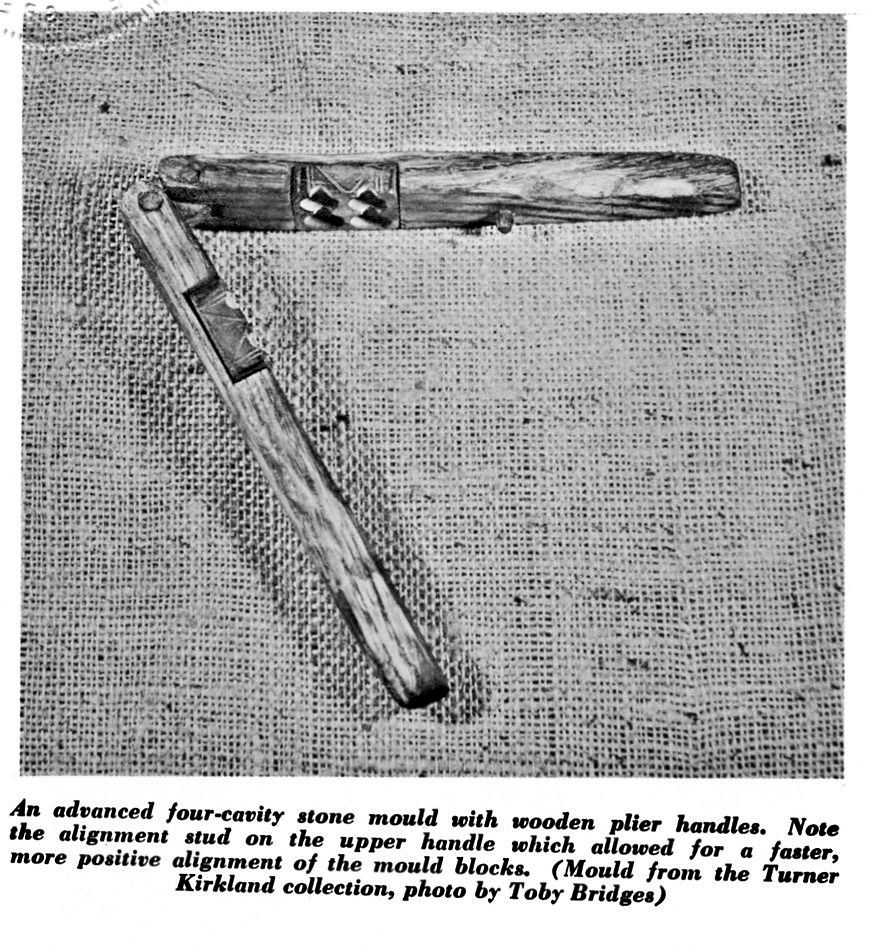

Another, similar one of stone, but makes 4 balls.

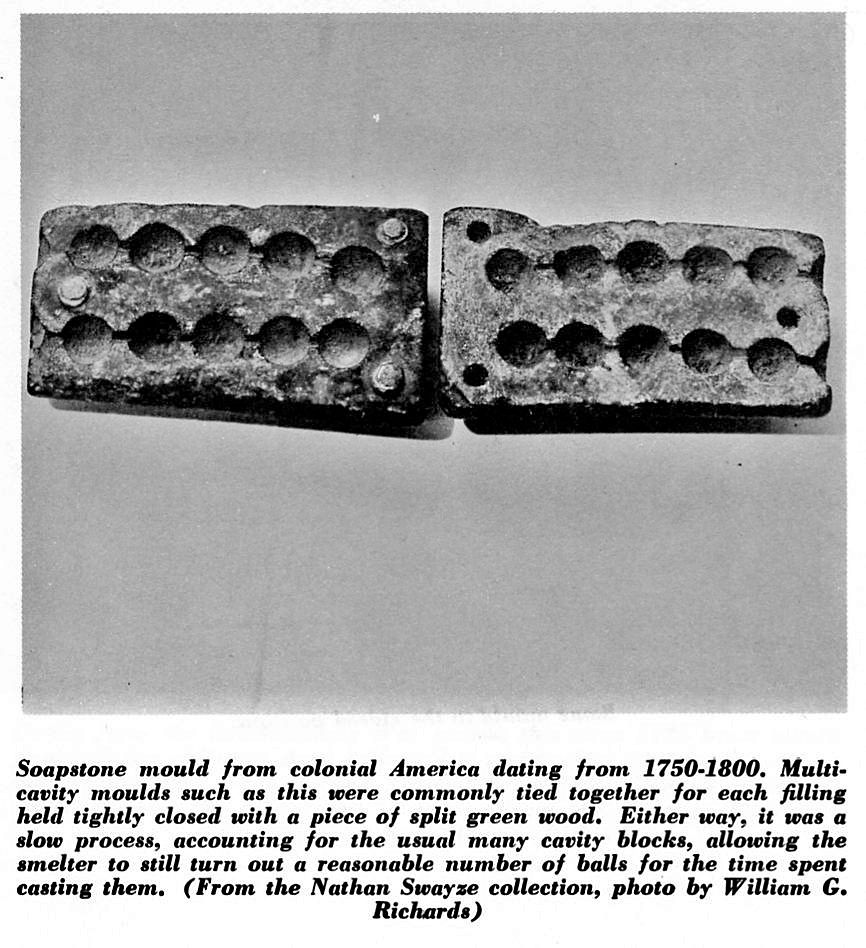

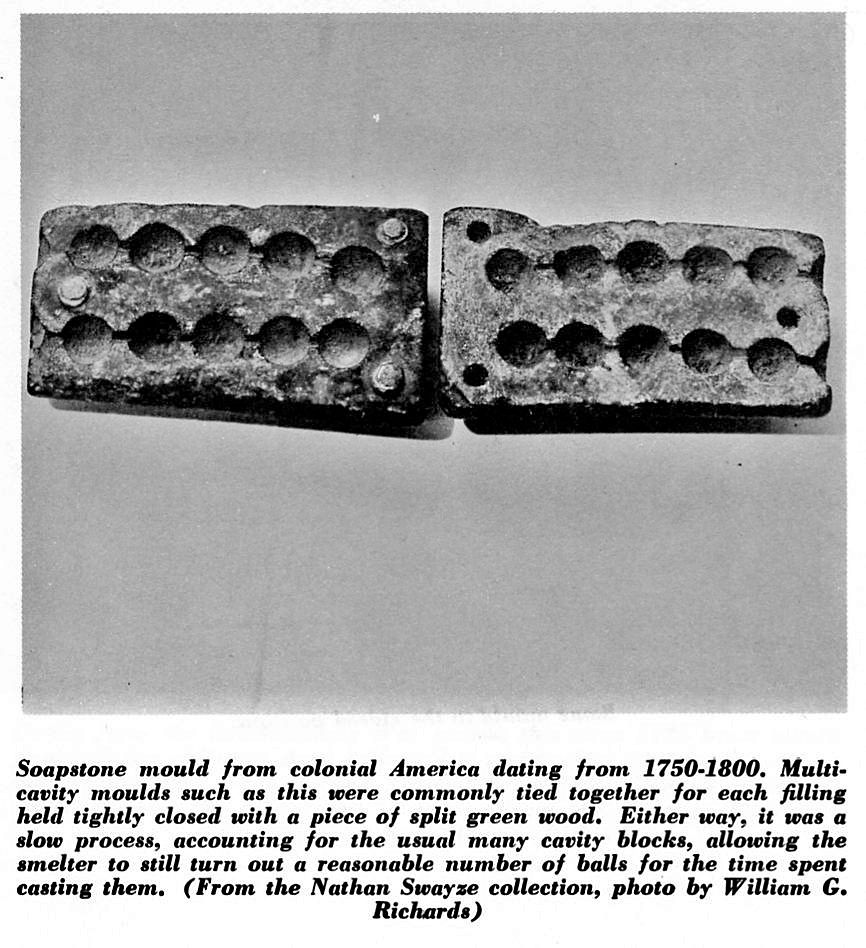

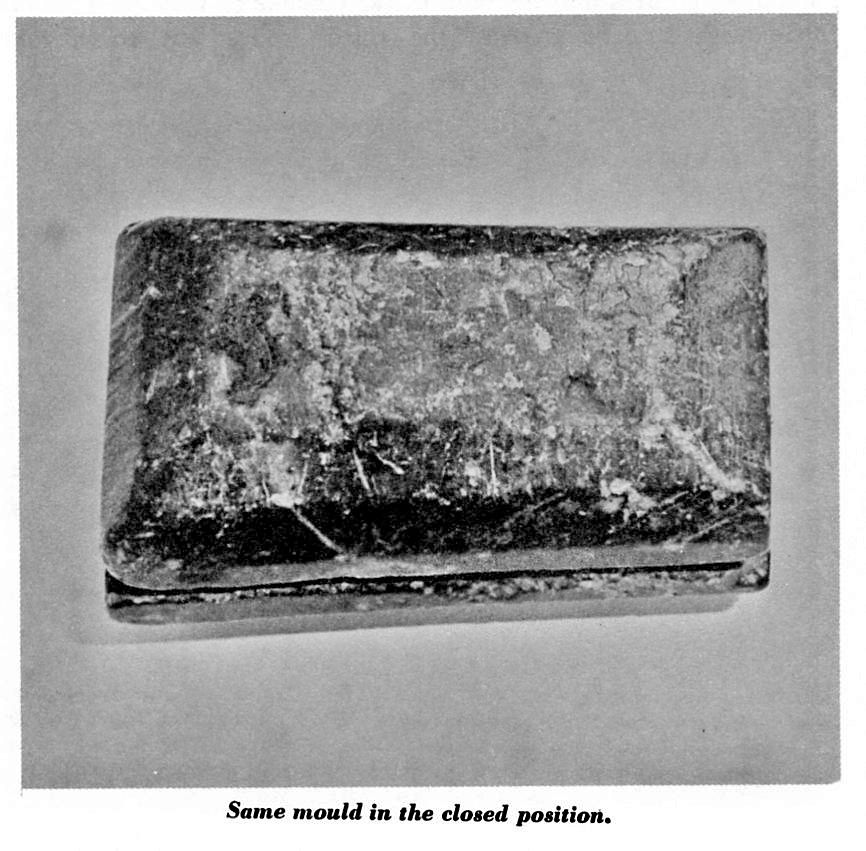

One of soapstone for multiple balls, open and closed. The two halves were apparently not attached or hinged, said to be held together by green wood strips while casting. Notice that the cavities are all lined up with gates between them in a row, so that you poured lead into the same hole for all, and it had to make its way through the whole row to reach the last one. Pretty hot lead, I’d guess.

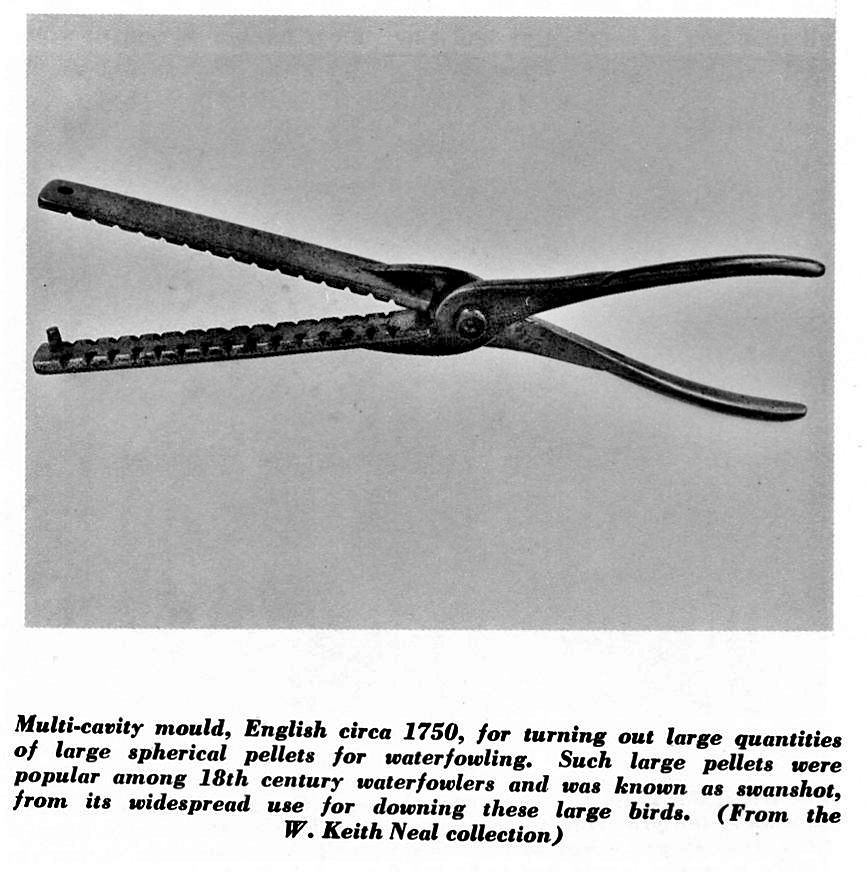

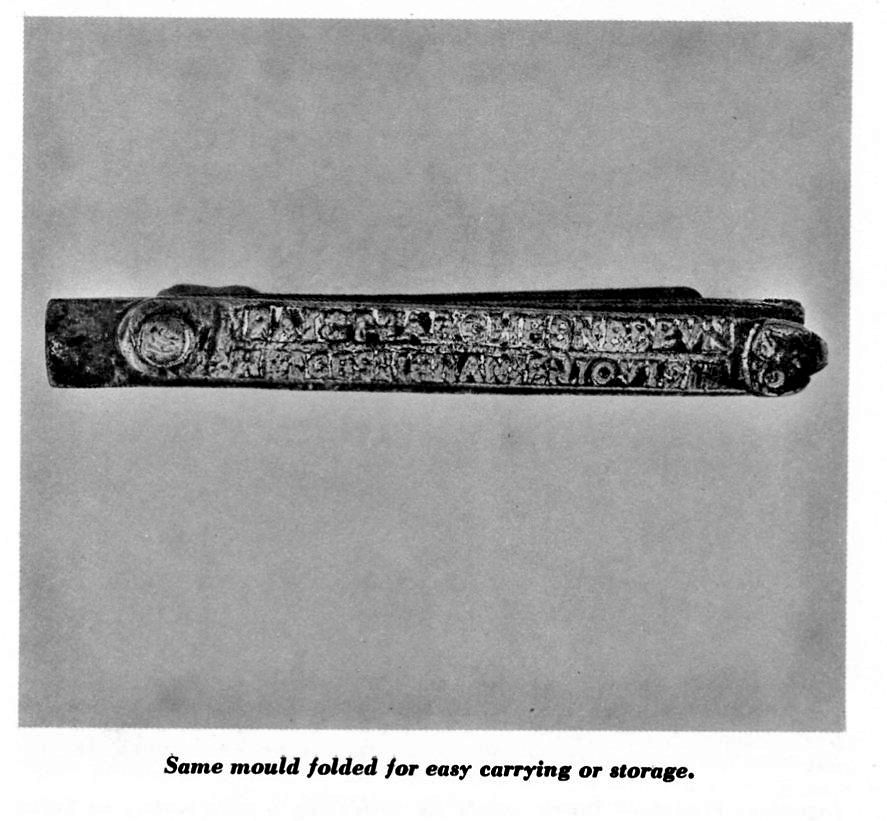

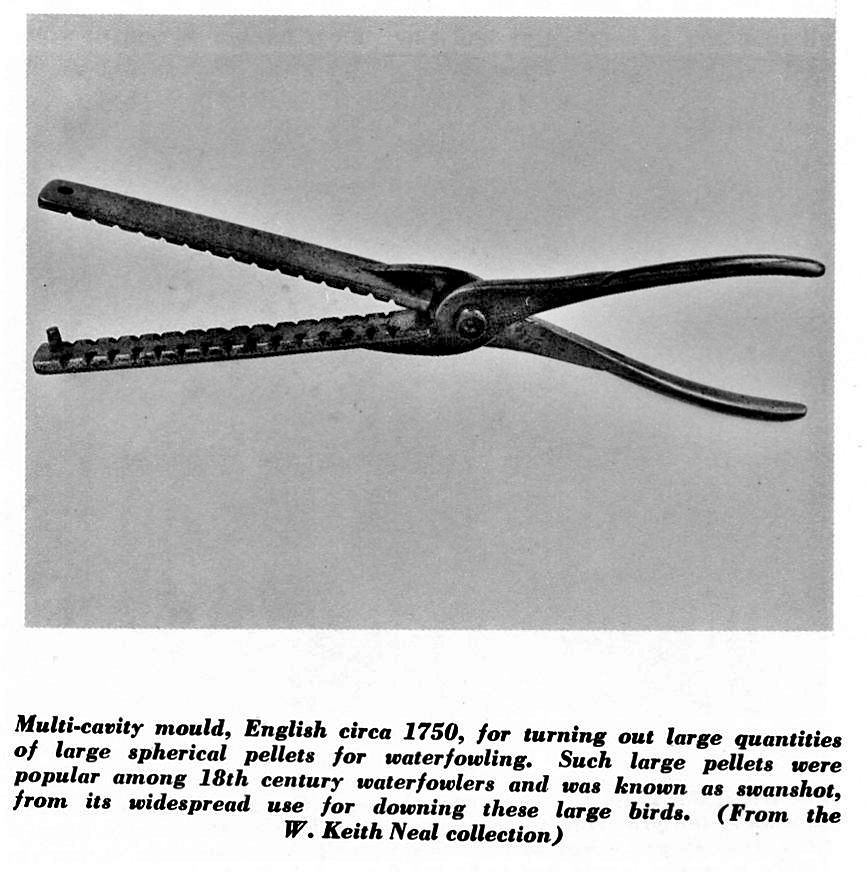

A multi-cavity one for swan shot:

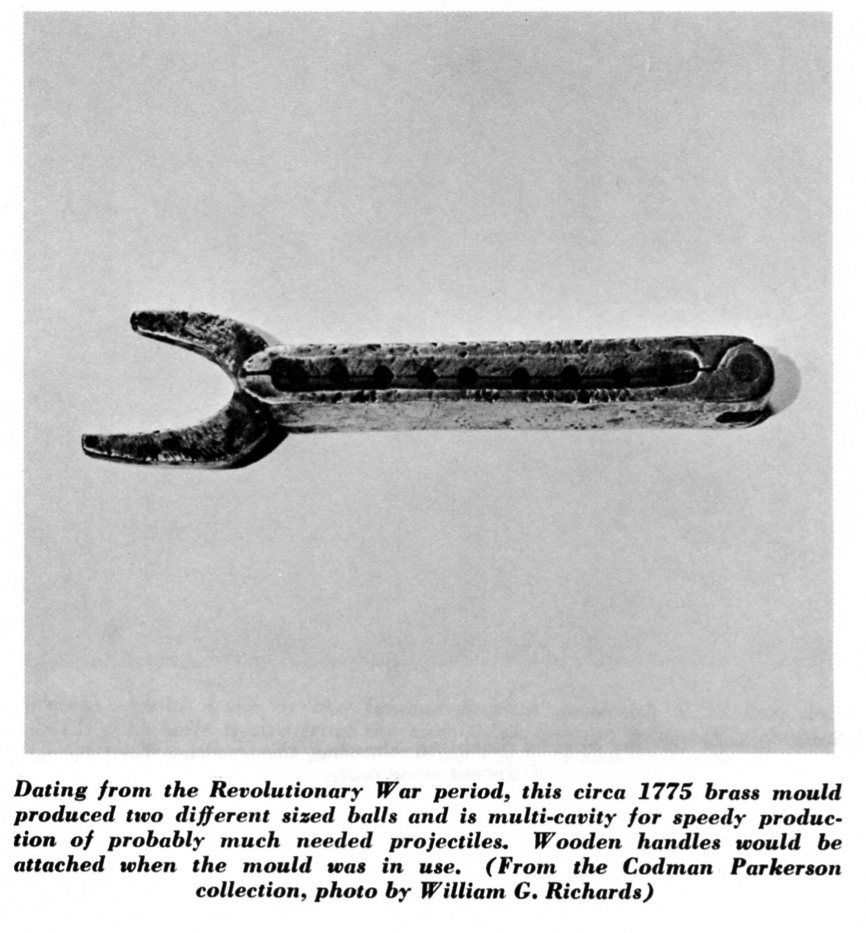

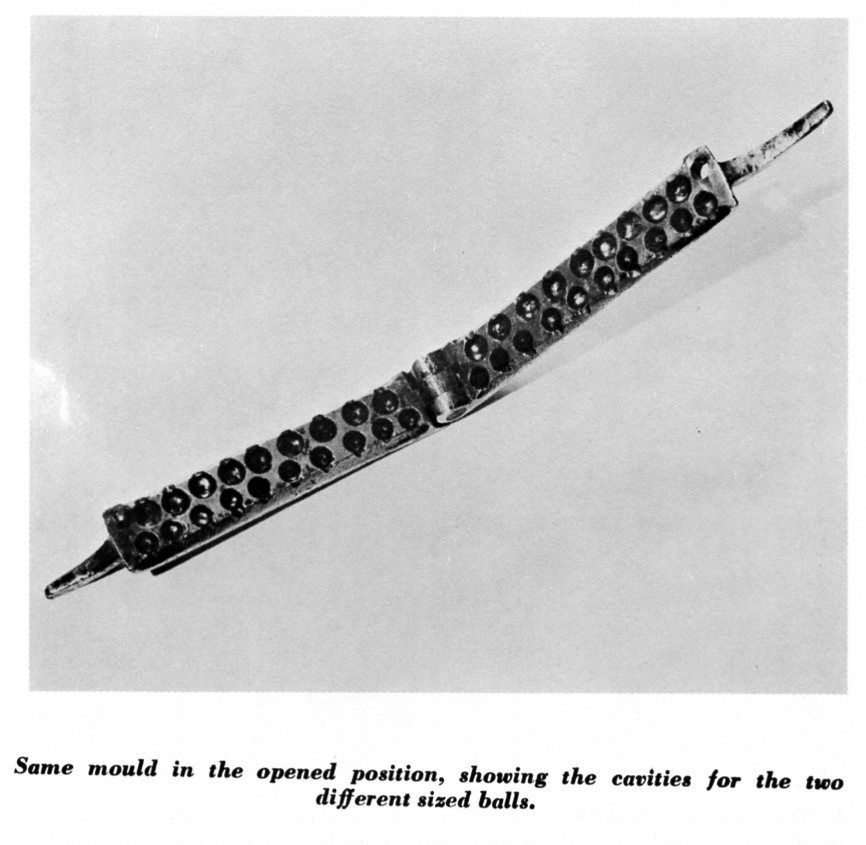

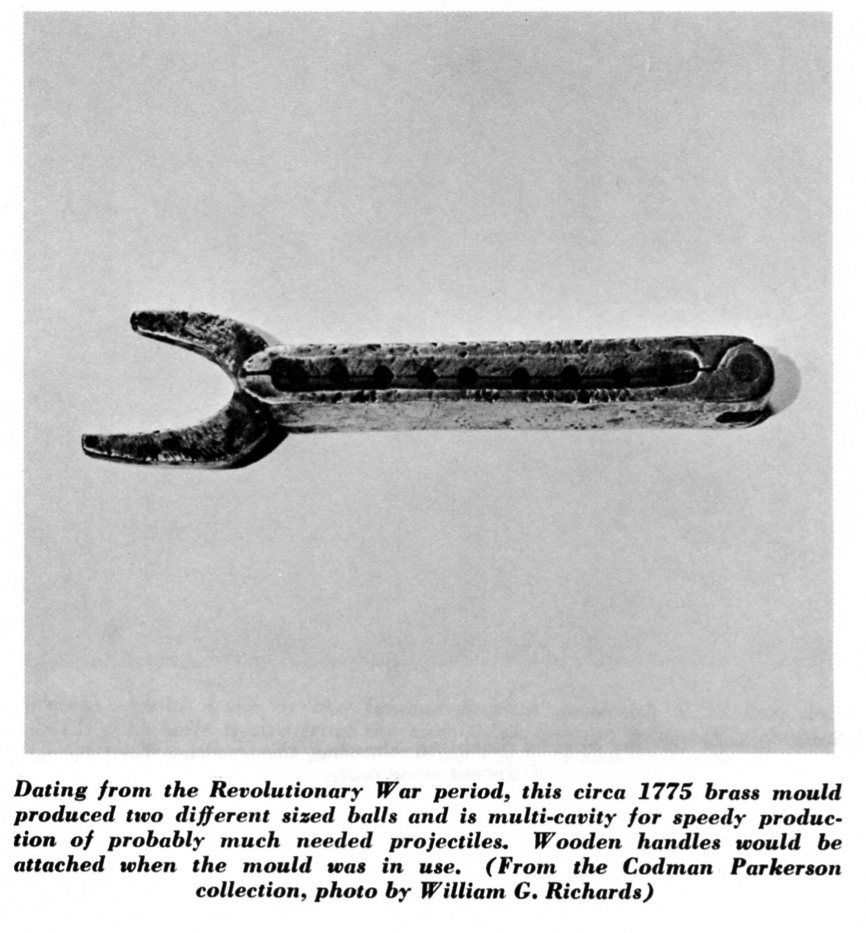

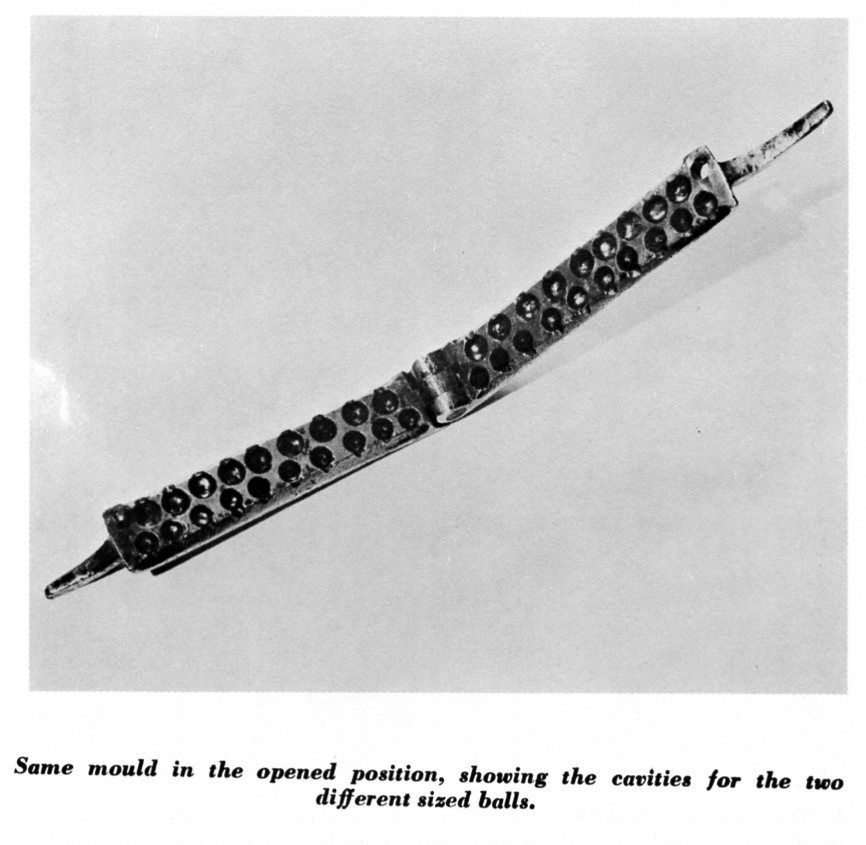

A multi-cavity one which casts 2 sizes of balls and uses wooden handles, closed and open:

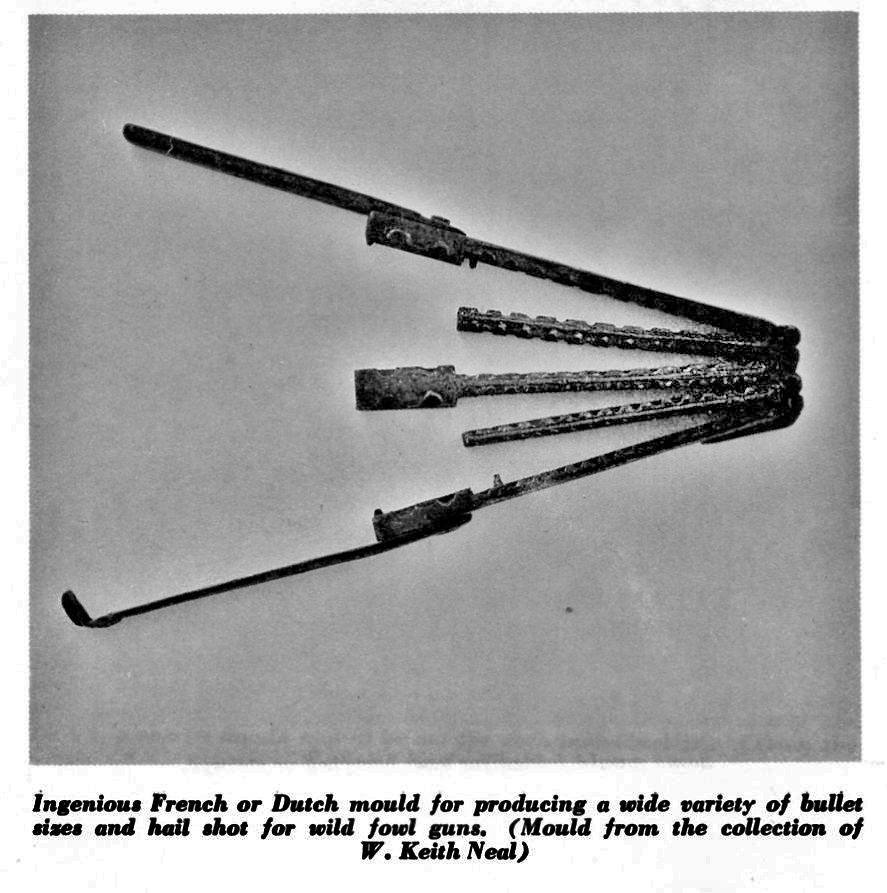

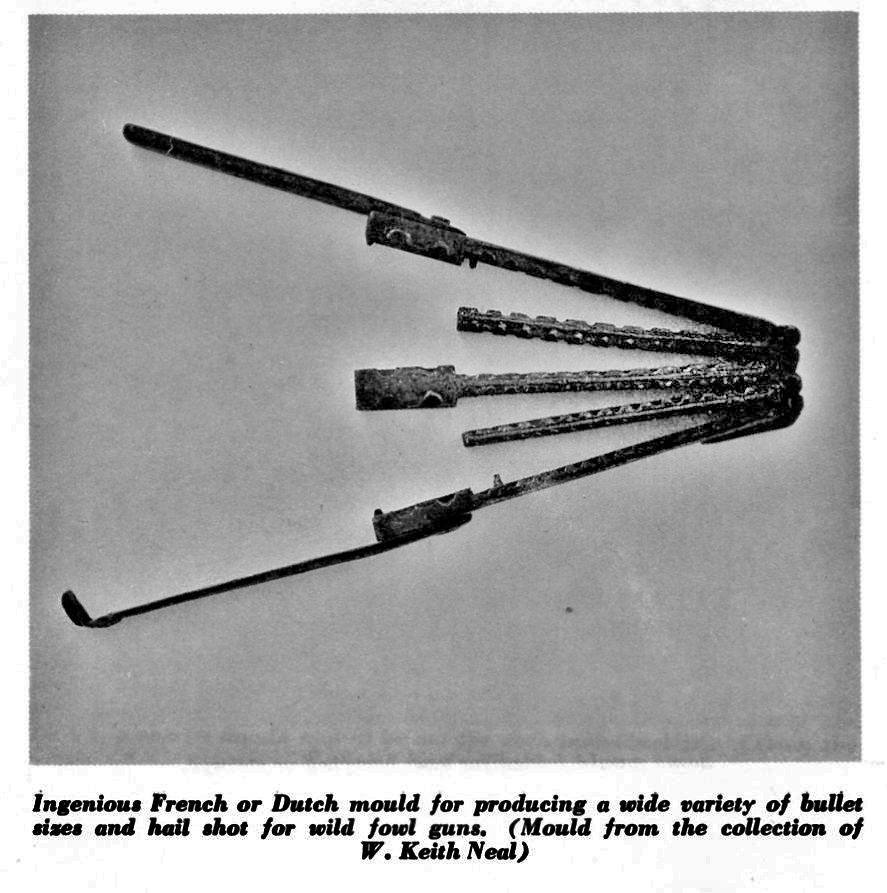

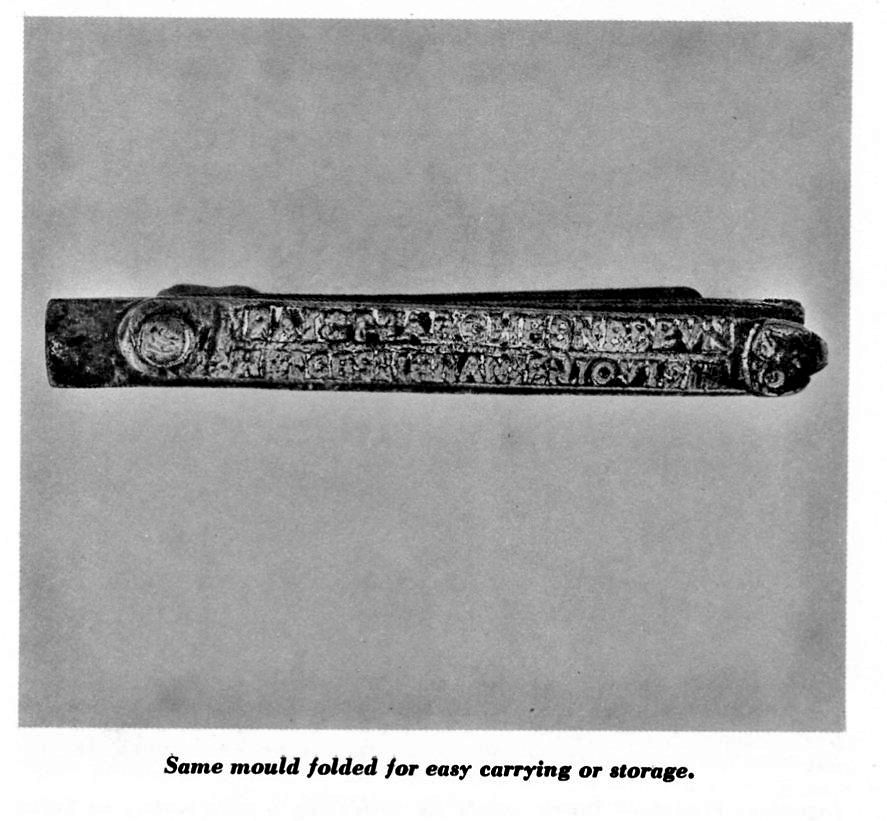

A very complex one which throws balls of several sizes as well as molded shot, open and closed:

Gang molds were apparently common. In 1768, Baynton, Warton and Morgan received these:

"4 Brass Bullet Moulds in Chest No, 3 to run 30 bullets at once in each (moulds at 55 shillings a piece)"

In the Shane interviews a couple of interesting entries, late 18th century.

James Wade: “He ran all his bullets in a pair of moulds that had a knife in them to cut them off at the neck as they were run.”

It would seem moulds with cutoffs were not common in his experience.

Benjamin Allen:” We had brass moulds that ran 60 shot on one side and 78 on the other.”

Spence

This one is made with stone blocks in a wooden handle. It’s not soapstone, but marble or limestone. Wonder how the caviries were cut.

Another, similar one of stone, but makes 4 balls.

One of soapstone for multiple balls, open and closed. The two halves were apparently not attached or hinged, said to be held together by green wood strips while casting. Notice that the cavities are all lined up with gates between them in a row, so that you poured lead into the same hole for all, and it had to make its way through the whole row to reach the last one. Pretty hot lead, I’d guess.

A multi-cavity one for swan shot:

A multi-cavity one which casts 2 sizes of balls and uses wooden handles, closed and open:

A very complex one which throws balls of several sizes as well as molded shot, open and closed:

Gang molds were apparently common. In 1768, Baynton, Warton and Morgan received these:

"4 Brass Bullet Moulds in Chest No, 3 to run 30 bullets at once in each (moulds at 55 shillings a piece)"

In the Shane interviews a couple of interesting entries, late 18th century.

James Wade: “He ran all his bullets in a pair of moulds that had a knife in them to cut them off at the neck as they were run.”

It would seem moulds with cutoffs were not common in his experience.

Benjamin Allen:” We had brass moulds that ran 60 shot on one side and 78 on the other.”

Spence