-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

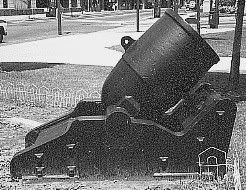

Coastal Mortar Replica

- Thread starter Heinrich

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Here is the progress on the carraige, basically the woodwork is done. I now only need to finish the where you can see the burn marks on the wood.

I used wallnut, and it took most of the afternoon to make the joints so that the beams in between the 2 rails penetrate the rails themselves.

I used wallnut, and it took most of the afternoon to make the joints so that the beams in between the 2 rails penetrate the rails themselves.

jeepwj992002

45 Cal.

- Joined

- Jan 3, 2007

- Messages

- 918

- Reaction score

- 0

Heinrich, that is going to be one wicked little mortar when you get done. :thumbsup:

TheDoubleD

40 Cal.

- Joined

- Mar 25, 2006

- Messages

- 347

- Reaction score

- 1

I'm working on one of those also. My cheek pieces are going to to be cut of out steel plate. The originals were cast iron.

The bore of my tube is 3.67 inch--6PDR.

The bore of my tube is 3.67 inch--6PDR.

HarborMaster

40 Cal.

- Joined

- Oct 21, 2005

- Messages

- 148

- Reaction score

- 0

Fantastic ! I am really lookingforward to this ., your Muzzle looks grand !!! not quite the average CW Coehorn., but French ? or English ? Very nice sir very nice indeed. :thumbsup:

:grin: Boy you make me regret not having finished machine shop during WWII, when they offered Machine Shop Practise as what they called "War Courses", while in High School. I have regretted this my entire life when I see the neat work being done by the skilled both here and in another field of endeavor (hobby) I am involved in. Since my uncle passed away I have had to pay people to do my machine work. Way to go---I will watch this story unfold until the day you fire that piece. :thumbsup:

jeepwj992002

45 Cal.

- Joined

- Jan 3, 2007

- Messages

- 918

- Reaction score

- 0

Looks outstanding Heinrich!!! :bow:

Guest

The big question is what grade of steel did you use for this project?

CP

CP

rifleshooter2

45 Cal.

- Joined

- Dec 31, 2004

- Messages

- 538

- Reaction score

- 5

Great job. I can't wait to see some smoke and fire.

Andy

Andy

EN19 is equal too barrel grade steel.

There is another one in circulation around our area that has been turned from EN9 steel which is 10 levels softer, and has been shooting for a long time. The owner measures all possible measurements on the barrel with little micrometers after every session, and there has been 0 micron change in any dimension. In fact his equipment is so fine that he has to measure the barrel at the same temperature.

There is another one in circulation around our area that has been turned from EN9 steel which is 10 levels softer, and has been shooting for a long time. The owner measures all possible measurements on the barrel with little micrometers after every session, and there has been 0 micron change in any dimension. In fact his equipment is so fine that he has to measure the barrel at the same temperature.

Similar threads

- Replies

- 10

- Views

- 207

- Replies

- 18

- Views

- 810