- Joined

- Nov 26, 2005

- Messages

- 5,017

- Reaction score

- 9,961

Hi,

I will occasionally post photos and descriptions of my work on a Chambers Little Fella's rifle kit I am building for Rifleman1776. Frank wants a small light rifle and this kit should fill the bill. Despite building >60 muzzleloaders over the years, I've only built one kit gun. That was a Navy Arms 1863 Springfield musket. I bought a Chambers Pennsylvania fowler kit from a third party who had started it but he had buggered it too badly for the stock to be salvaged. Anyway, this is the first Chambers kit that I will build from the start. I examined many Chambers kits over the years and believe they are mostly very good offerings. This one, however, is not one of their best and I will get into that as I go along. Regardless, it will turn out fine in the end.

I am going to turn the rifle into an early Berk's County style gun as much as I can. The stock has a lot of extra wood so I have room to maneuver. The first step is to seat the breech of the barrel. It needs to slide back about 1/8" so the vent hole can be located in front of the end of the breech plug.

The stock shaper cut the inlet for the breech plug bolster and breech of the barrel too deep. I am going to seal the barrel channel with a varnish thin coat of AcraGlas anyway, so that will fill in the space. The barrel needed to be inlet a little deeper overall so that the vent hole would be level with the pan of the lock. You don't have any room to shift the lock around because the inlet for it restricts it to one position to avoid any gaps (more about that later). Anyway, lowering the barrel eliminated most of the void at the breech.

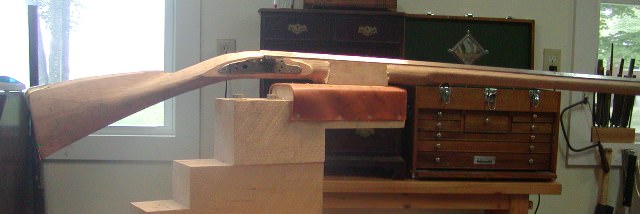

Next I wanted to thin the web of wood between the barrel channel and the ramrod groove. Note how much extra thickness there is below the bottom of the muzzle cap. That means the ramrod will hang below the cap with an obvious gap. No gun will ever go out of my shop looking like that. The ramrod hole is already drilled so I cannot move it. Instead, I scraped and filed the groove so the web of wood thins toward the muzzle. The small taper won't affect the rod going in and out but it improves the appearance tremendously by slimming the forestock. Further, I will deepen the groove right near the muzzle so it can accommodate a substantial swell in the ramrod tip. I will discard the 3/8" rod that came with the kit and use one of my 7/16" rods that will be tapered to fit the gun and have a swell at the end.

As you can see there is a lot of extra wood along the forestock that will be removed. A lot of extra!

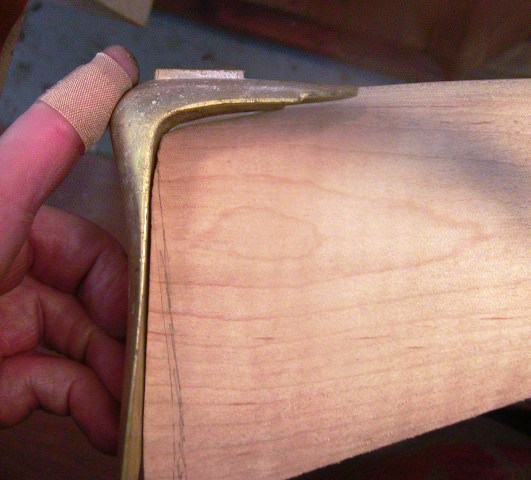

I inlet the breech plug. The plug is well fitted to the barrel and I reshaped it to look like those commonly seen on early Berk's guns. I would have liked to narrow it a bit but the machined inlet requires the full width of the plug near the end. Before inletting, I filed away the radius between the bolster and under side of the tang. That radius really makes inletting difficult. Instead, I always file the plug square despite the inlet having a radius on top. However, by moving the barrel back, I eliminated most of that radius. I filed draft on the edges of the tang and inlet it, which went easily.

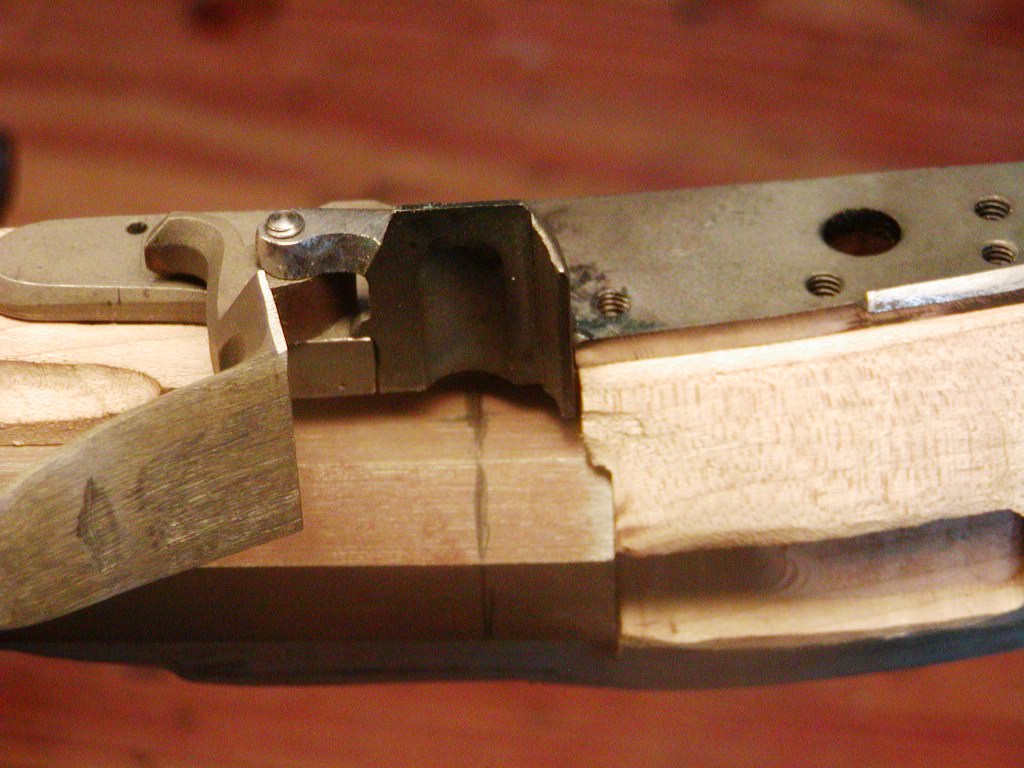

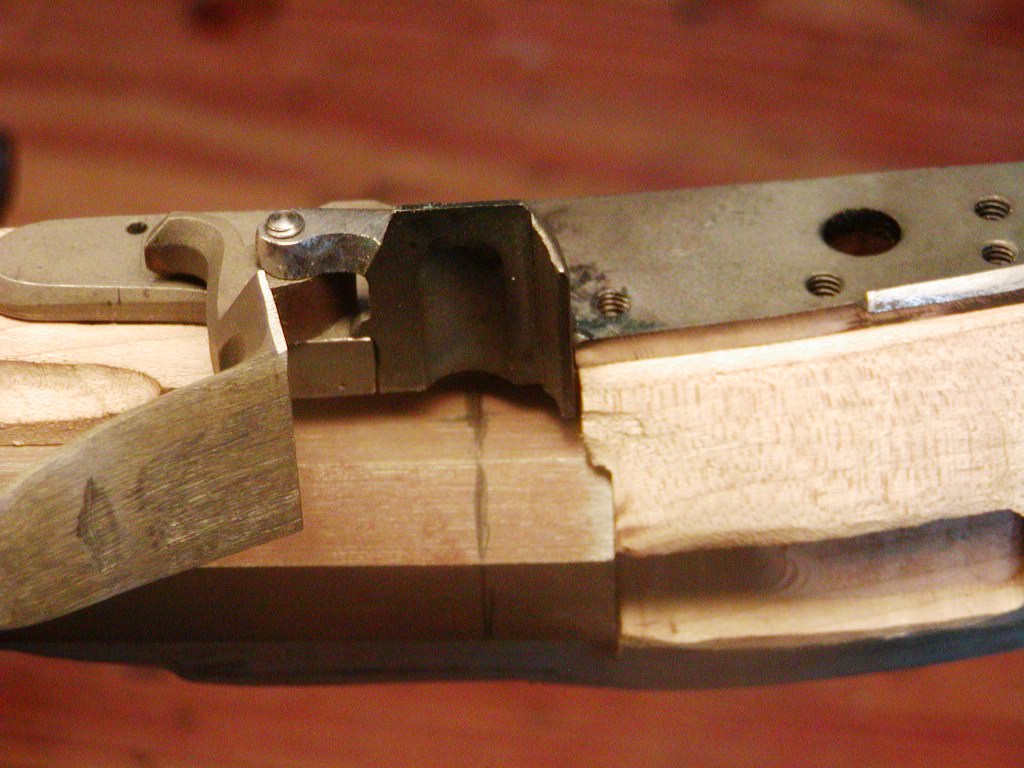

Next up is inletting the lock. Unfortunately, this Siler lock had some issues. The internals are fine and it works very well, but the pan and bolster were poorly fitted to the plate, something I never encountered on a Chambers-built Siler before. Moreover, the lock barely fills the machine inlet and there are tiny gaps around the tail of the plate. I suspect those gaps would disappear when the lock is fully inlet and finish is applied. However, I won't take those chances and I really don't much like the triangular tail of a Siler anyway. Many of the early Berks rifles had locks with thicker and slightly more rounded tails. So, I got out my welder, fixed the fit of the pan and added metal to the tail. Shaped the tail and also reshaped the pan bridle to get rid of the ugly one on the Siler. The result is HC and looks pretty good. Well, that is where I am and I will post some more soon. I am building this rifle and also am well on my way building a late flint English rifle, which I have to turn my attention to for a few days.

dave

I will occasionally post photos and descriptions of my work on a Chambers Little Fella's rifle kit I am building for Rifleman1776. Frank wants a small light rifle and this kit should fill the bill. Despite building >60 muzzleloaders over the years, I've only built one kit gun. That was a Navy Arms 1863 Springfield musket. I bought a Chambers Pennsylvania fowler kit from a third party who had started it but he had buggered it too badly for the stock to be salvaged. Anyway, this is the first Chambers kit that I will build from the start. I examined many Chambers kits over the years and believe they are mostly very good offerings. This one, however, is not one of their best and I will get into that as I go along. Regardless, it will turn out fine in the end.

I am going to turn the rifle into an early Berk's County style gun as much as I can. The stock has a lot of extra wood so I have room to maneuver. The first step is to seat the breech of the barrel. It needs to slide back about 1/8" so the vent hole can be located in front of the end of the breech plug.

The stock shaper cut the inlet for the breech plug bolster and breech of the barrel too deep. I am going to seal the barrel channel with a varnish thin coat of AcraGlas anyway, so that will fill in the space. The barrel needed to be inlet a little deeper overall so that the vent hole would be level with the pan of the lock. You don't have any room to shift the lock around because the inlet for it restricts it to one position to avoid any gaps (more about that later). Anyway, lowering the barrel eliminated most of the void at the breech.

Next I wanted to thin the web of wood between the barrel channel and the ramrod groove. Note how much extra thickness there is below the bottom of the muzzle cap. That means the ramrod will hang below the cap with an obvious gap. No gun will ever go out of my shop looking like that. The ramrod hole is already drilled so I cannot move it. Instead, I scraped and filed the groove so the web of wood thins toward the muzzle. The small taper won't affect the rod going in and out but it improves the appearance tremendously by slimming the forestock. Further, I will deepen the groove right near the muzzle so it can accommodate a substantial swell in the ramrod tip. I will discard the 3/8" rod that came with the kit and use one of my 7/16" rods that will be tapered to fit the gun and have a swell at the end.

As you can see there is a lot of extra wood along the forestock that will be removed. A lot of extra!

I inlet the breech plug. The plug is well fitted to the barrel and I reshaped it to look like those commonly seen on early Berk's guns. I would have liked to narrow it a bit but the machined inlet requires the full width of the plug near the end. Before inletting, I filed away the radius between the bolster and under side of the tang. That radius really makes inletting difficult. Instead, I always file the plug square despite the inlet having a radius on top. However, by moving the barrel back, I eliminated most of that radius. I filed draft on the edges of the tang and inlet it, which went easily.

Next up is inletting the lock. Unfortunately, this Siler lock had some issues. The internals are fine and it works very well, but the pan and bolster were poorly fitted to the plate, something I never encountered on a Chambers-built Siler before. Moreover, the lock barely fills the machine inlet and there are tiny gaps around the tail of the plate. I suspect those gaps would disappear when the lock is fully inlet and finish is applied. However, I won't take those chances and I really don't much like the triangular tail of a Siler anyway. Many of the early Berks rifles had locks with thicker and slightly more rounded tails. So, I got out my welder, fixed the fit of the pan and added metal to the tail. Shaped the tail and also reshaped the pan bridle to get rid of the ugly one on the Siler. The result is HC and looks pretty good. Well, that is where I am and I will post some more soon. I am building this rifle and also am well on my way building a late flint English rifle, which I have to turn my attention to for a few days.

dave