- Joined

- Nov 26, 2005

- Messages

- 5,010

- Reaction score

- 9,945

Hi,

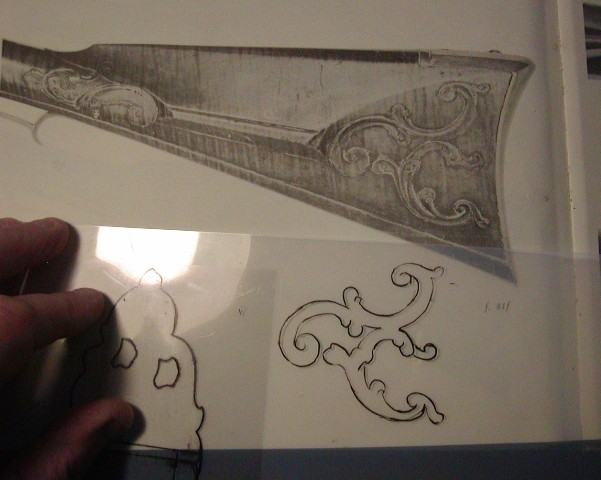

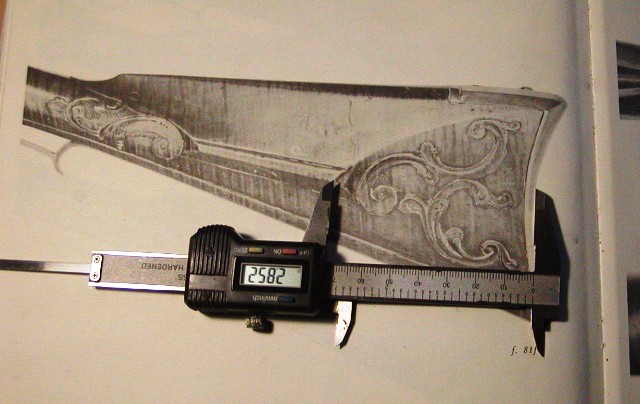

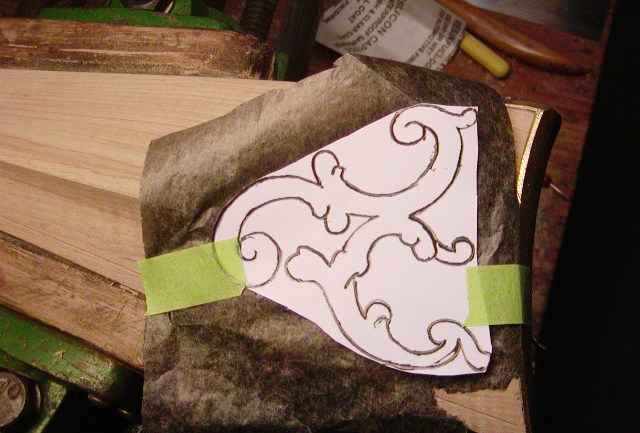

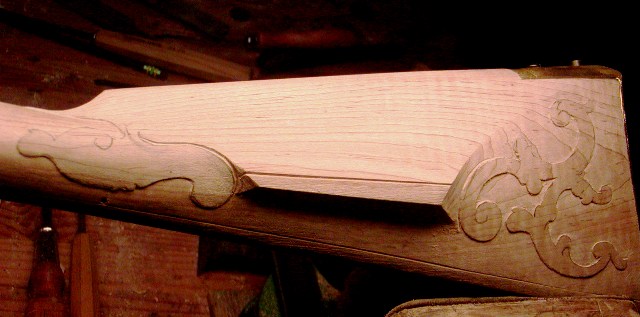

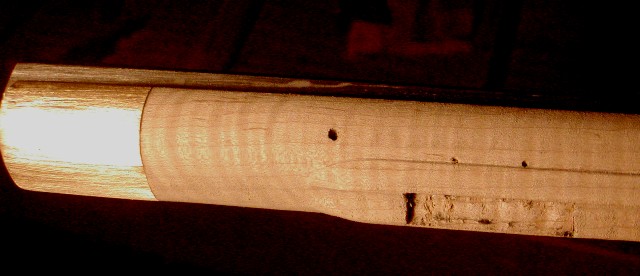

I got some shaping done in preparation for carving. I essentially bring the gun almost to a condition ready for stain before carving. I wanted to show how I handle the breech area of the stock. As far as I can tell, Haines shaped that area the same way. The stock should be flush or almost flush with the barrel flats at the breech so there is no significant step down from the surface of the wood at the breech to the barrel. There are plenty of original long rifles by less skilled old-time makers who did not do that but they were not of the same caliber as Isaac Haines. I use a coarse half round file to shape the wood into a slight concave surface that brings the edge of the wood very close to barrel flats.

I do it equally on both sides of the barrel tang.

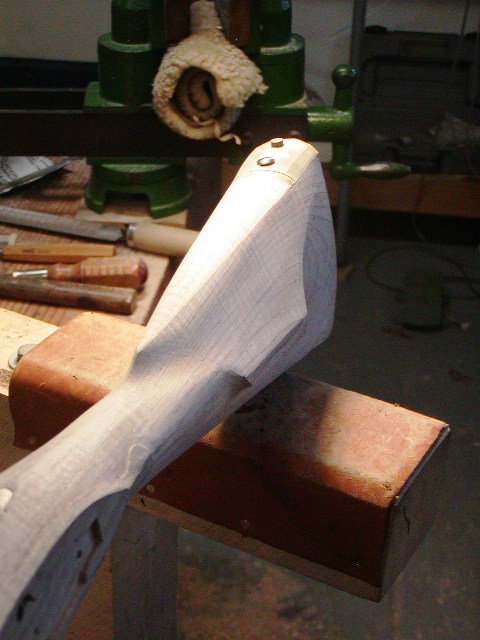

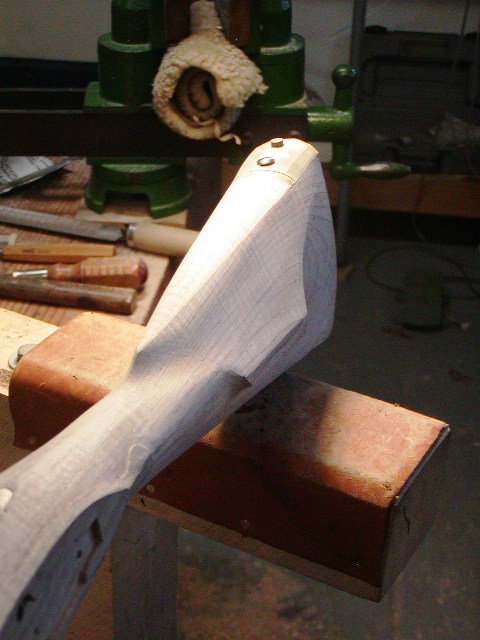

Doing that on the lock side also allows you to avoid the ugly notch so many guys file in the wood to clear the shoulder on the flint cock. Those notches are always blemishes and Haines saw no need for them and neither do I. By making the stock concave or at least flat but flush with the barrel, the flat molding around the lock will, by default, be very thin behind the pan. That thinness combined with tapering the edge of the lock mortice inward to expose more of the lock plate bolster where the flint cock rests eliminates the need for a notch. It is a neat way to make room for the flint cock and it looks so much better than a notch. It is also the way Haines handled the problem.

Isaac Haines was a very great American gun maker. He was great because he maintained crisp beautiful architecture in his guns and was a superb stock decorator. It is a shame that we don't know more about him. Like Isaac Berlin, Haines demonstrated architectural and decorative sophistication well above most of his contemporary gun makers in 18th century America. To presume to make a gun labeled an "Isaac Haines" means you accept the challenge of matching his design and artistic genius. To do that, I have to recreate that architecture and crisp style, which establishes the background for the carved decoration. In addition, it results in a rifle that fits and handles really well for shooting. Using files and scrapers I shaped the butt stock in preparation for carving. Note the crisp angles, facets and edges. That is how the original rifle was done and the result is a gun that is efficient, functional, and beautiful. Those lines and facets also serve as the borders for the carving. Haines was a very great artist.

dave

I got some shaping done in preparation for carving. I essentially bring the gun almost to a condition ready for stain before carving. I wanted to show how I handle the breech area of the stock. As far as I can tell, Haines shaped that area the same way. The stock should be flush or almost flush with the barrel flats at the breech so there is no significant step down from the surface of the wood at the breech to the barrel. There are plenty of original long rifles by less skilled old-time makers who did not do that but they were not of the same caliber as Isaac Haines. I use a coarse half round file to shape the wood into a slight concave surface that brings the edge of the wood very close to barrel flats.

I do it equally on both sides of the barrel tang.

Doing that on the lock side also allows you to avoid the ugly notch so many guys file in the wood to clear the shoulder on the flint cock. Those notches are always blemishes and Haines saw no need for them and neither do I. By making the stock concave or at least flat but flush with the barrel, the flat molding around the lock will, by default, be very thin behind the pan. That thinness combined with tapering the edge of the lock mortice inward to expose more of the lock plate bolster where the flint cock rests eliminates the need for a notch. It is a neat way to make room for the flint cock and it looks so much better than a notch. It is also the way Haines handled the problem.

Isaac Haines was a very great American gun maker. He was great because he maintained crisp beautiful architecture in his guns and was a superb stock decorator. It is a shame that we don't know more about him. Like Isaac Berlin, Haines demonstrated architectural and decorative sophistication well above most of his contemporary gun makers in 18th century America. To presume to make a gun labeled an "Isaac Haines" means you accept the challenge of matching his design and artistic genius. To do that, I have to recreate that architecture and crisp style, which establishes the background for the carved decoration. In addition, it results in a rifle that fits and handles really well for shooting. Using files and scrapers I shaped the butt stock in preparation for carving. Note the crisp angles, facets and edges. That is how the original rifle was done and the result is a gun that is efficient, functional, and beautiful. Those lines and facets also serve as the borders for the carving. Haines was a very great artist.

dave