- Joined

- Mar 7, 2007

- Messages

- 648

- Reaction score

- 2,004

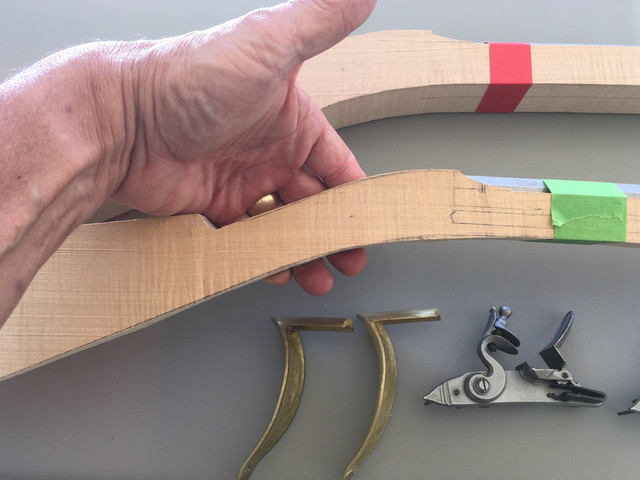

Many years ago now I wanted to build two, three quarter scale flintlock rifles for my then two small daughters. I was buying stock wood and inletting services from Fred Miller back then and contacted him to ask for a piece of excellent maple thick enough to split in half lengthwise so that I could make two nearly matching stocks for the small rifles. He sent me a great blank which I subsequently band-sawed into rough shaped stocks.

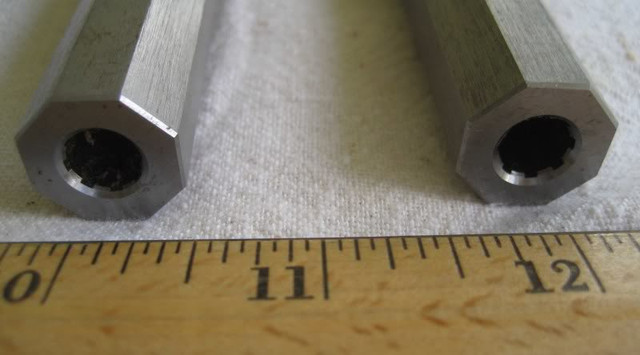

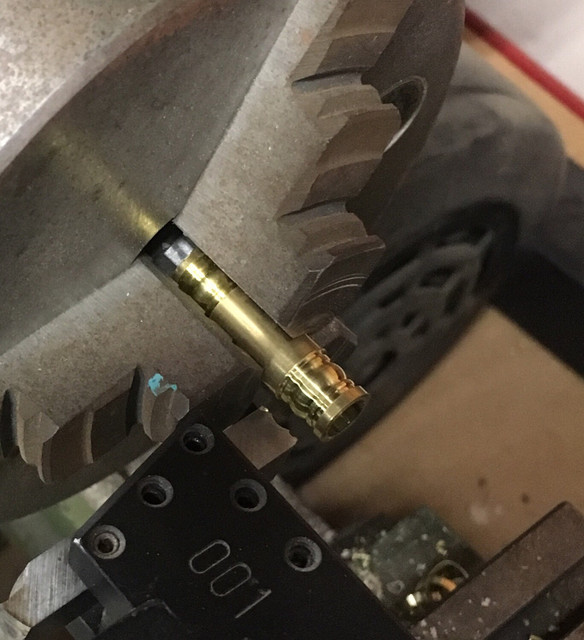

Even before that time, some 20 years ago, I had purchased two Douglas barrels in 32 caliber. They were 13/16 inch across the flats. I cut the barrels to a length of 32 inches and then re-machined the octagon to just a little under .695" across the flats. I made breech plugs for the barrels and, somewhere along the way, found some very small butt plate and trigger guard castings that were close enough to use on these rifles.

I was obviously not moving at the speed of light (or even the speed of dark) but I kept thinking about what I might want to do as far as the little rifle design went. Finding a lock the right size was an issue. I originally purchased two of the “Becky” locks and spent a good deal of time polishing and tuning them. But before I finished with the polishing, I discovered Stan Hollenbaugh‘s locks. Stan had a standard size rifle lock and then a smaller size lock, that I liked much better than the Beckys, and that he was producing at the time... so I purchased two of those.

As these things work out, all of that thinking and gathering was more than 15 years ago now. Also as these things happen, both of my girls are grown and have left home....the youngest is a country singer in Nashville and the oldest one, married and living in New York, just recently had our first grandchild. As they taught me during my plebe year at the US Naval Academy, “time, tide, and formation wait for no man.” Time had truly gotten away from me in the maelstrom of making a living, and life in general, and I never did get a chance to finish the little rifles for my own daughters.

So now, almost two decades further on, I am starting in again. With my grandson only four months old right now, I figure that I might get this done in time for him to use it as a lad. More specifically, at my age, if I miss the boat this time, the opportunity will have passed forever as I am rapidly running out of "air speed, altitude, and ideas !" For those of you who care to follow along, I will start in on at least one of these little rifles (I may do both at the same time.... but perhaps not) and post the progress here.

Even before that time, some 20 years ago, I had purchased two Douglas barrels in 32 caliber. They were 13/16 inch across the flats. I cut the barrels to a length of 32 inches and then re-machined the octagon to just a little under .695" across the flats. I made breech plugs for the barrels and, somewhere along the way, found some very small butt plate and trigger guard castings that were close enough to use on these rifles.

I was obviously not moving at the speed of light (or even the speed of dark) but I kept thinking about what I might want to do as far as the little rifle design went. Finding a lock the right size was an issue. I originally purchased two of the “Becky” locks and spent a good deal of time polishing and tuning them. But before I finished with the polishing, I discovered Stan Hollenbaugh‘s locks. Stan had a standard size rifle lock and then a smaller size lock, that I liked much better than the Beckys, and that he was producing at the time... so I purchased two of those.

As these things work out, all of that thinking and gathering was more than 15 years ago now. Also as these things happen, both of my girls are grown and have left home....the youngest is a country singer in Nashville and the oldest one, married and living in New York, just recently had our first grandchild. As they taught me during my plebe year at the US Naval Academy, “time, tide, and formation wait for no man.” Time had truly gotten away from me in the maelstrom of making a living, and life in general, and I never did get a chance to finish the little rifles for my own daughters.

So now, almost two decades further on, I am starting in again. With my grandson only four months old right now, I figure that I might get this done in time for him to use it as a lad. More specifically, at my age, if I miss the boat this time, the opportunity will have passed forever as I am rapidly running out of "air speed, altitude, and ideas !" For those of you who care to follow along, I will start in on at least one of these little rifles (I may do both at the same time.... but perhaps not) and post the progress here.