Mountain Stalker

32 Cal

Howdy,

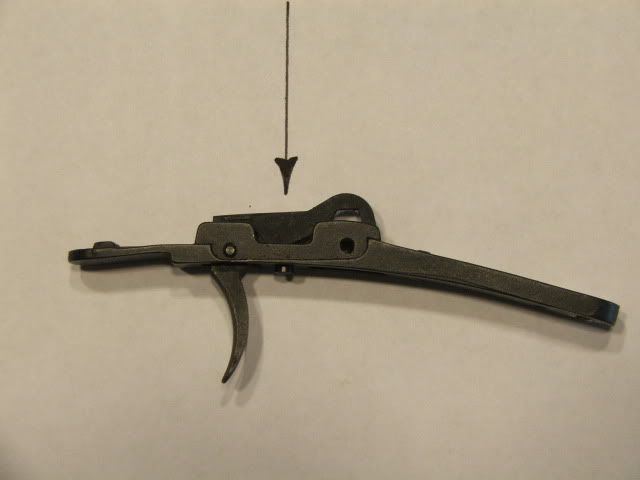

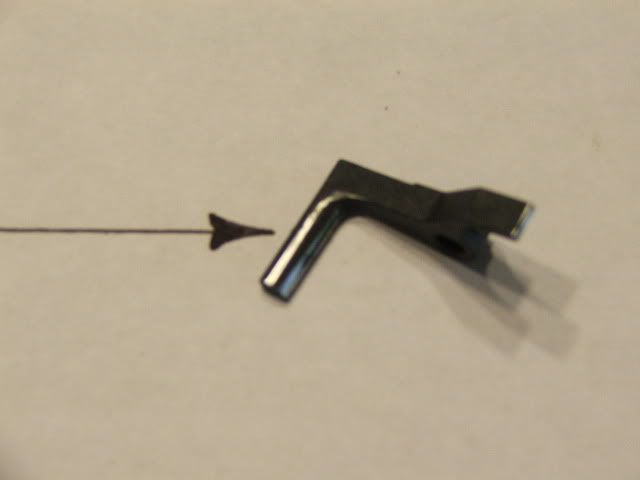

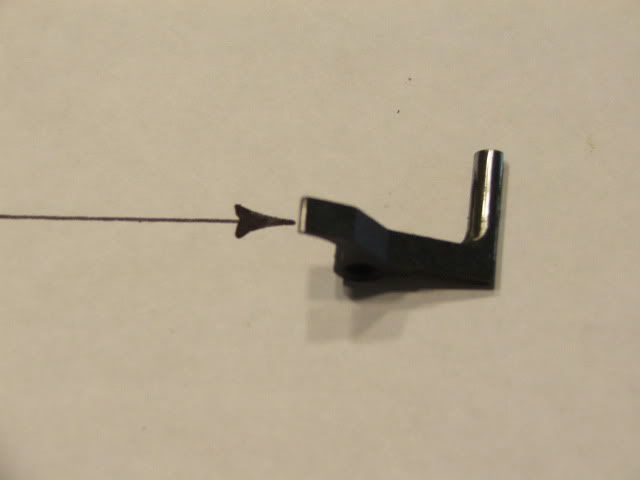

I recently bought a brand new Lyman Deerstalker percussion in a .50 and would like to know others' experiences with the lock and trigger. My conservitive estimate would be that it breaks at well over 6 lbs. Cocking the gun revealed some rougness when the hammer is cocked back from half to full. I took out the lock and looking at it I can see that a square edge of the fly dragging on the sear is causing the rough operation while the hamer is travelling back past halfcock. It doesn't make much difference when cocking silently with the trigger depressed as in a hunting situation, otherwise it is gritty. As for the heavy trigger, I've found that on occasion I can squeeze it about 1/32" and stop before it breaks. I don't mind a little travel before the break, but would like to smoothen and reduce the pull to between 3 or 4 lbs. Was wondering whether polishing the contact surface on the tumbler, especially around the full-cock notch would improve trigger pull. Anyone have relevant experience in this regard with the Deerstalker or Trade rifle?

Thanks,

MS

I recently bought a brand new Lyman Deerstalker percussion in a .50 and would like to know others' experiences with the lock and trigger. My conservitive estimate would be that it breaks at well over 6 lbs. Cocking the gun revealed some rougness when the hammer is cocked back from half to full. I took out the lock and looking at it I can see that a square edge of the fly dragging on the sear is causing the rough operation while the hamer is travelling back past halfcock. It doesn't make much difference when cocking silently with the trigger depressed as in a hunting situation, otherwise it is gritty. As for the heavy trigger, I've found that on occasion I can squeeze it about 1/32" and stop before it breaks. I don't mind a little travel before the break, but would like to smoothen and reduce the pull to between 3 or 4 lbs. Was wondering whether polishing the contact surface on the tumbler, especially around the full-cock notch would improve trigger pull. Anyone have relevant experience in this regard with the Deerstalker or Trade rifle?

Thanks,

MS