Phil Coffins

69 Cal.

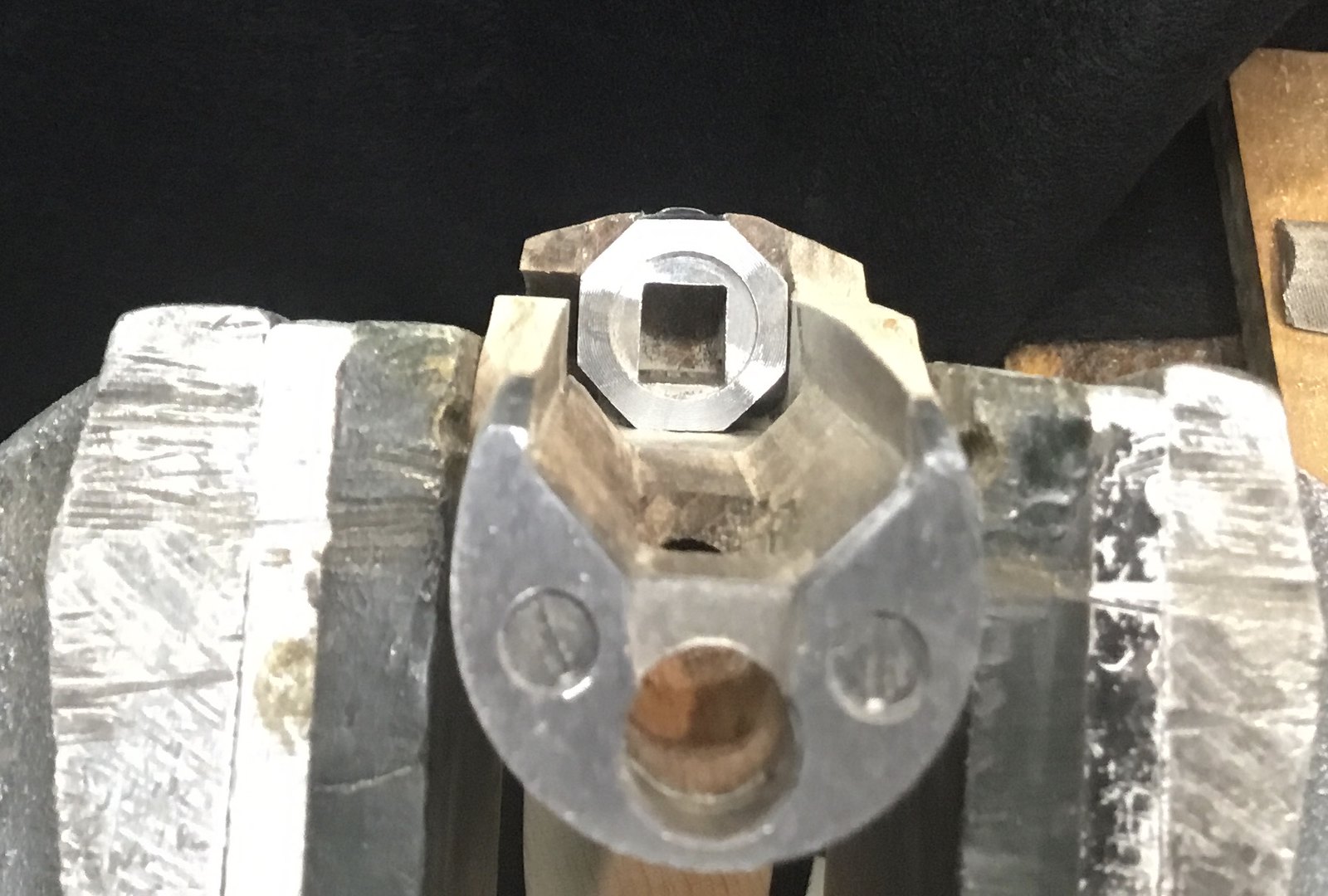

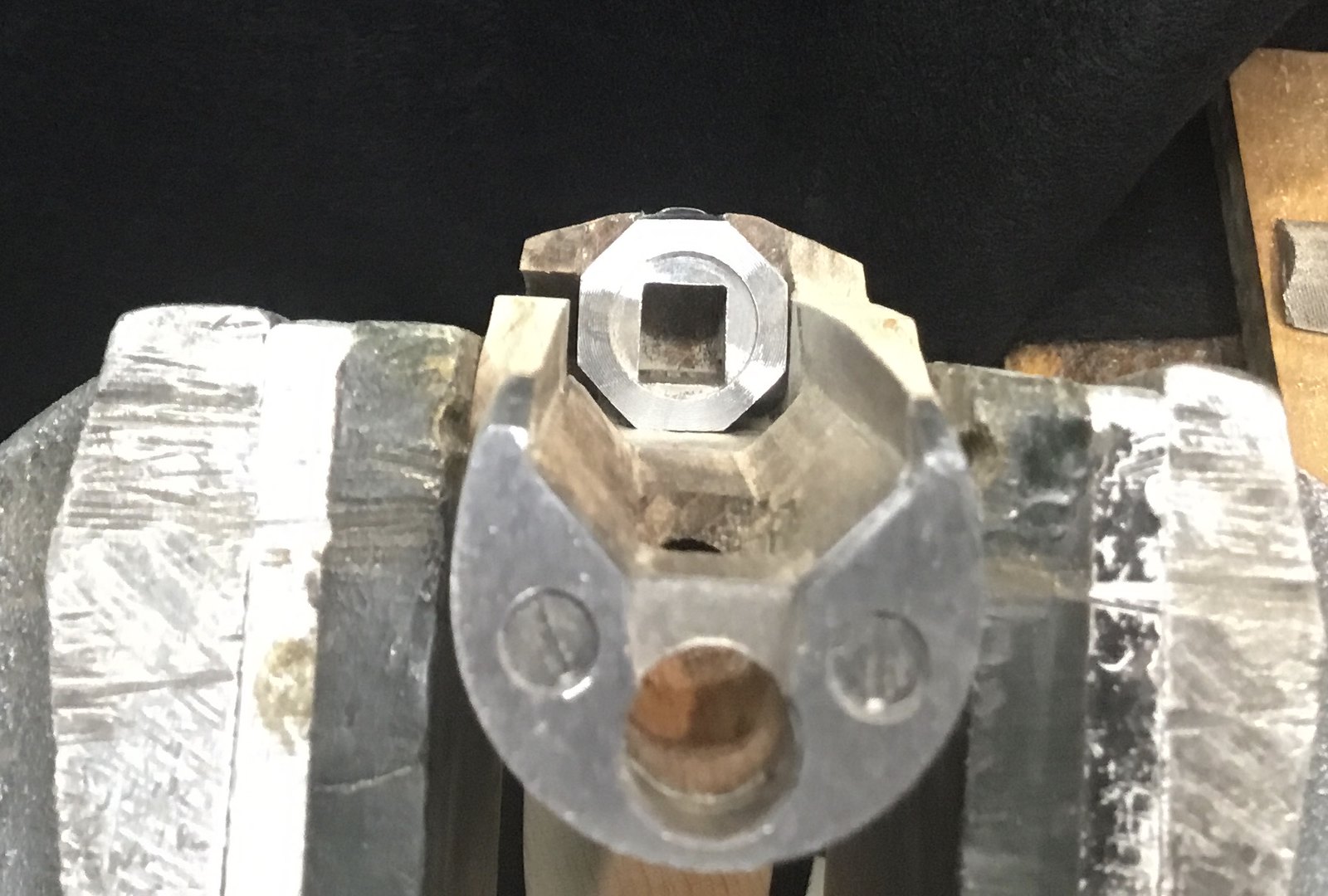

The Lyman pistol is a good easy one to build and shoot. It also has many points that can easily be refined, here’s some of them. After inspecting all the parts the metal parts need cleaned up and de-burred. Then I recrowned the muzzle and plugged the screw in the breech. The breech was also reshaped to suit my taste. The tang needed only a tiny bit of inletting to have it seat back onto the wood. There’s a lot of wood to remove all the way around. The trigger set very low in the wood and removing that made a neater job of it.

F2B45227-4150-4CBA-B681-21A76096CC92 by Oliver Sudden, on Flickr

F2B45227-4150-4CBA-B681-21A76096CC92 by Oliver Sudden, on Flickr

The tang set at angle and to deep so a pea sized bit of filler squared to up. Then wood was removed down to it and shaped to trim this area.

96572B0E-72B3-4DFF-B349-D63AF3634B20 by Oliver Sudden, on Flickr

96572B0E-72B3-4DFF-B349-D63AF3634B20 by Oliver Sudden, on Flickr

The forend wood is trimmed down to the level of the escutcheons and narrower at the barrel. The nose cap evened up also.

5D81B7E1-3464-4E45-B3CE-ADED1B9AEF1B by Oliver Sudden, on Flickr

5D81B7E1-3464-4E45-B3CE-ADED1B9AEF1B by Oliver Sudden, on Flickr

Next the lock panels are trimmed and reshaped as well as the wrist. The standard Lyman feels square in this area and I prefer a more oval shape.

D8F7C0C3-03A8-476C-9233-857D13F7572B by Oliver Sudden, on Flickr

D8F7C0C3-03A8-476C-9233-857D13F7572B by Oliver Sudden, on Flickr

Its still a bit rough but all the heavy work is done.

F2B45227-4150-4CBA-B681-21A76096CC92 by Oliver Sudden, on Flickr

F2B45227-4150-4CBA-B681-21A76096CC92 by Oliver Sudden, on FlickrThe tang set at angle and to deep so a pea sized bit of filler squared to up. Then wood was removed down to it and shaped to trim this area.

96572B0E-72B3-4DFF-B349-D63AF3634B20 by Oliver Sudden, on Flickr

96572B0E-72B3-4DFF-B349-D63AF3634B20 by Oliver Sudden, on FlickrThe forend wood is trimmed down to the level of the escutcheons and narrower at the barrel. The nose cap evened up also.

5D81B7E1-3464-4E45-B3CE-ADED1B9AEF1B by Oliver Sudden, on Flickr

5D81B7E1-3464-4E45-B3CE-ADED1B9AEF1B by Oliver Sudden, on FlickrNext the lock panels are trimmed and reshaped as well as the wrist. The standard Lyman feels square in this area and I prefer a more oval shape.

D8F7C0C3-03A8-476C-9233-857D13F7572B by Oliver Sudden, on Flickr

D8F7C0C3-03A8-476C-9233-857D13F7572B by Oliver Sudden, on FlickrIts still a bit rough but all the heavy work is done.

723A5B54-B2B5-4088-ABEA-81DDEE2E59B7

723A5B54-B2B5-4088-ABEA-81DDEE2E59B7