Like most things in life if you like WD40 its great, if you don't like it then you can always find something wrong with it.

-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WD-40 Test

- Thread starter Zonie

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Because the source, type, and amount of aliphatic hydrocarbons used has changed over the years. Not to mention other differences in MSDS sheets. and regulatory compliance and My personal observation using it for more than 50 years.

Thanks for that. I will admit that it has changed though that has not affected the product's effectiveness that I have seen from use. I buy it in gallons and use pump sprayers rather than aerosol cans.

WD-40 will forever get bad PR as long as folks use it as perservative or lubricant. It is neither though it has limited function as both for a short term. It will protect a surface for a short time in mild conditions and it will also lubricate while in its liquid form (fresh application but then water will lubricate too). It can be used to clean items though there are better things for that. It is a very handy penetrating oil and can lubricate when removing or installing fastners. I use it on firearms after cleaning to remove all water from inside and outside of the barrel. I keep a 5 gal. bucket with about 3 gals. of WD in it and put my revolvers and other parts in it to remove all the water after I have cleaned them (I do that in a bucket of hot soapy water). After I allow them to dry, lube them and if I'm not going to use them again right away I oil them.

WD-40 is a fantastic product and it would be difficult to imagine life without it (and duct tape too ) now that we are accustomed to it. I do get extremely tired of hearing people slam it because it failed them in an application it was never intended for.

) now that we are accustomed to it. I do get extremely tired of hearing people slam it because it failed them in an application it was never intended for.

WD-40 is a fantastic product and it would be difficult to imagine life without it (and duct tape too

Eddie2002

40 Cal

I've used it as a solvent to help spread heavier oil while cleaning a firearm for long term storage. I've also soaked a bore with WD40 after a shooting match for a little protection till I can do a proper cleaning. Not saying it's the cat's meow but it has it's uses.

I do get extremely tired of hearing people slam it because it failed them in an application it was never intended for.

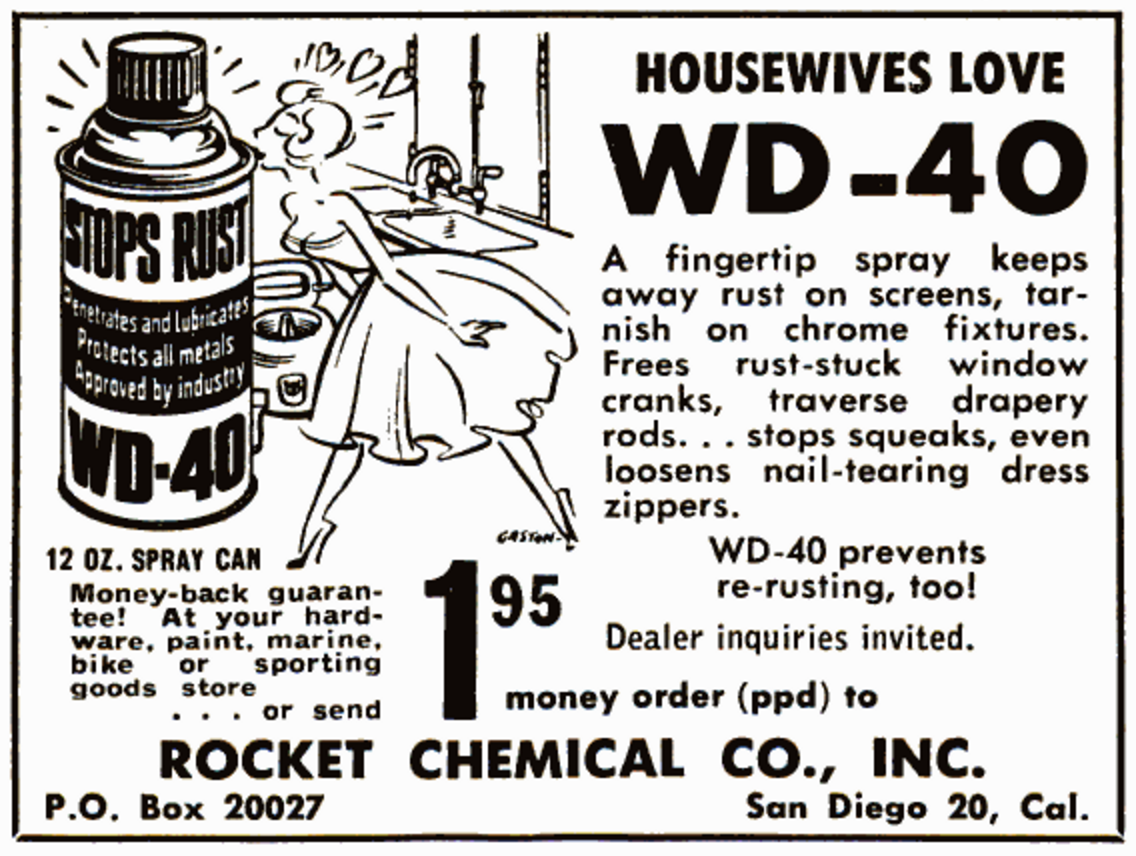

In defense of all those people who "Slam" WD-40, I would note that the company has long marketed the product as a virtual cure-all for just about everything.

And their 20001+ uses list.

https://www.slideshare.net/projectsalescorp/wd-40-2000uses-list

Last edited:

hanshi

Cannon

Along with WD40, 3 in 1 oil was a mainstay in my early years and still lends a hand from time to time.

- Joined

- Jan 3, 2004

- Messages

- 14,767

- Reaction score

- 313

I do get extremely tired of hearing people slam it because it failed them in an application it was never intended for.

Right on their site it claims to prevent rust.

I have used WD40 (purchase in gallon containers, not in spray cans) in the bores of my muzzleloaders since the mid 1970s with no issues. Think nothing about putting a muzzleloader up for months at a time with nothing but WD in the bore or on the barrel. Have lived in NC and all the humidity it can bring for over 25 years, but do store my guns in a air conditioned environment. I do not trust WD for rust protection other than storage at my house or taking a trip to the range in fair weather. For harsh conditions, there is a long list of better performing products.

I will NOT use WD on any gun mechanisms (locks for example) as have I have personally witnessed problems in cold weather. Years ago buddy had a firing pin freeze in place (he had a modern gun and it was below 0°F). Had to warm it on the truck defrosters to free it up. Gun was down until he could disassemble, clean, properly lubricate and reassemble.

As far as gumming things up or solidifying, have also seen that happen. Work in manufacturing. A few years ago someone decided to use WD to assist an assembly issue. Sprayed the stuff in a container, then dipped the part in it. Wasn’t long before there was what looked like a whiteish grease like substance in the container (they continued to spray more in the container as it emptied).... soon we had this grease in the assemblies and had to scrap or rework thousands of parts. The part spec said it had to function between -40°F and 125°F. Believe they locked up before our test chamber got to 10°F. Who wants that part in their vehicle?

I will NOT use WD on any gun mechanisms (locks for example) as have I have personally witnessed problems in cold weather. Years ago buddy had a firing pin freeze in place (he had a modern gun and it was below 0°F). Had to warm it on the truck defrosters to free it up. Gun was down until he could disassemble, clean, properly lubricate and reassemble.

As far as gumming things up or solidifying, have also seen that happen. Work in manufacturing. A few years ago someone decided to use WD to assist an assembly issue. Sprayed the stuff in a container, then dipped the part in it. Wasn’t long before there was what looked like a whiteish grease like substance in the container (they continued to spray more in the container as it emptied).... soon we had this grease in the assemblies and had to scrap or rework thousands of parts. The part spec said it had to function between -40°F and 125°F. Believe they locked up before our test chamber got to 10°F. Who wants that part in their vehicle?

- Joined

- Mar 1, 2016

- Messages

- 35

- Reaction score

- 23

about 75 I acquired my first BP rifle, life changed and it was stored for a decade, would take it out every so often, spray some WD40 down the barrel and put it back, years later our gunsmith at work asked to bring it over, he was sure the can said it

contained water, we pulled the breach plug, clean as a whistle, I pointed out the can said it "displaces" water. I, too, have heard the formula has changed, heard once the original contained DMSO and that was taken out of the formula.

My father was an automotive machinest, he could talk a block out of the boiling tank, air dry it off with compressed air, spare the cylinder with wd or CRC and watch the water bead up out of the pores and run down the cylinder wall.

contained water, we pulled the breach plug, clean as a whistle, I pointed out the can said it "displaces" water. I, too, have heard the formula has changed, heard once the original contained DMSO and that was taken out of the formula.

My father was an automotive machinest, he could talk a block out of the boiling tank, air dry it off with compressed air, spare the cylinder with wd or CRC and watch the water bead up out of the pores and run down the cylinder wall.

Pete G

76 Cal.

If it moves and should not, use duct tape.

If it not move and should, use WD40.

If it not move and should, use WD40.

For what it's worth, I've just ended my test.

With all of the comments on the forum about WD-40 gumming things up or solidifying into something that blasting powder can't dislodge and how WD-40 will totally screw up any gun that it is sprayed on, I did a test.

It might not be the best test and it didn't involve anything that was rusty but it should have shown that after all thinning solvents have evaporated it becomes some sort of a solid that could do those things.

The test involved taking the metal lid off of one of my old tins of CCI percussion caps and spraying the WD-40 into it to a depth of a little less than 1/16" deep.

To give it something to bond in place I degreased a steel washer and tossed it in.

I set this out on my BBQ in the hot Arizona sun figuring that not only should the heat evaporate all of the solvents but sunlight being what it is, anything that might solidify because of ultra-violet radiation would become semi-solid. (Tru-Oil drys and hardens in less than an hour in the Arizona sunlight.)

After 5 days of sitting out there in temperatures that reached 114°F in the shade yesterday I will say the amount of fluid was greatly decreased. Now there is only enough to dampen the bottom of the lid with a small fillet around the corner where the flat area meets the sides.

So what is this stuff that is left? If I were to give my best description I would have to say, oil. Very close to 30w oil.

The washer is still wet from the oil and it easily moves around if I touch it.

Based on this I will say that in my opinion, WD-40 leaves a medium weight oil behind after it has "dried out".

A lot of things like tumbler locks use springs under the tumblers that are so light that 30 weight oil will tend to "gum them up", but for anything on a muzzleloading gun I don't think using it will cause any problems whatsoever.

And now, let the debate begin.

PS: I will keep the lid and washer inside for another week or so to see what happens in a nice, cool, refrigerated house and let you all know what happens.

Zonie, When I first ran across WD 40, me and another fellow were running a junior rifle club in our small town, in a damp basement, and we had six DCM sponsored 22 rifles.This was about 1970. Our storage area was an old steel cabinet with a poor fitting plywood door. Money was at a premium for our shooting club, Even though we were an NRA accepted club and were able to buy shells through the government. Anyway, rust was the everyday problem, so when spring would come we would close till Late fall. The year I found WD-40, I soaked those guns stocks and all and put them in the cabinet. In August or September I went checked on them, the barrels including the actions had all turned white and I about had a heart attack. It didn't take long to discover it would wipe right off, the stock shining beautiful and the actions and barrels cleaned up readily with Hoppies #9. Two things about the conditions, the humidity was high, the temperature was about constant 70°. Most of the floor was nothing but dirt, the walls were cement. Since that time I've used it when necessary with no reservations, but it does seem to dry and not furnished much lubrication later on. Just to drop or two of light machine oil with it seems to keep things working.

Squint

Eutycus

Cannon

Some people might say that I'm harping on the subject because I mentioned it more than once, But humidity really is a factor.

My experience is WD-40 residue will suck moisture and it also hardens so metal scrapers are needed. Even the airline I worked at gave it up. I have used it to flush chips making bullet molds but I wash it off with hot water and dish soap real fast. NEVER will it go on or in a gun.

- Joined

- Feb 3, 2013

- Messages

- 1,624

- Reaction score

- 1,268

Oh, Ok. I see the difference here. I don't use the WD40 in pressure cans: have many years back. I use the product on my wood working tables to keep moisture disbursed and have used it for automotive rubber for squeaky chassis. I buy in in gallon cans and use spray bottles.

Could it be that the propellent in the containers disperse the formulation.

My smoke poles just get a layer of 3&1 oil and a layer of lithium grease, or automotive chassis grease on lock parts and under the barrel. I am not recommending my method for the pricey keepsake weapons, just my hunting rifles and fowlers. Cartridge weapons that collect dust at my house, different ball game.

Could it be that the propellent in the containers disperse the formulation.

My smoke poles just get a layer of 3&1 oil and a layer of lithium grease, or automotive chassis grease on lock parts and under the barrel. I am not recommending my method for the pricey keepsake weapons, just my hunting rifles and fowlers. Cartridge weapons that collect dust at my house, different ball game.

- Joined

- Feb 3, 2013

- Messages

- 1,624

- Reaction score

- 1,268

My experience is WD-40 residue will suck moisture and it also hardens so metal scrapers are needed

Straight WD40 will almost get to be a shellac if left for ant length of time. I have to clean saw tables off with solvent and wax them down to use them, but it still protects the iron from moisture, and that is what I am after.

8 BORE

50 Cal.

Bottom line

Use it or don't use it !!!!!!

Use it or don't use it !!!!!!

it's a different product now than it was 30 years ago.

Coincidentally, it was thirty years ago that my father's shotguns, after having sat for about 18 months, in New Mexico humidity (or lack of it), that my father's shotgun locks were gummed up.

Twenty five years ago I was sold a modern handgun by a widow who's husband had been a retired detective and he had used 3-In-One oil on the action and cylinder

I'm sure as a regular lubricant and attempt at rust prevention it was fine..., just not long term storage.

For the record, I use WD-40 all the time on my BP firearms. I just know NOT to use the stuff on the rifles or guns that might sit on the rack for a year or more; while I will pull those down, and check and apply exterior rust preventative, and check the bores, I don't necessarily pull the locks and check those every time.

LD

if you must use a spray oil for actual rust protection, Barricade or RIG #2 are probably some of the best I've used as far as a light gun oil.

- Joined

- Jan 3, 2004

- Messages

- 14,767

- Reaction score

- 313

Here in the land of salt water, salt air and high humidity LPS has become a top choice for everything from aircraft to boats to guns, opting for LPS1, LPS2 or LPS3 for the specific job. Barricade and Rig products are good too, but not so versatile for broad uses, as LPS products are on most every store shelf.

Archer 756

40 Cal.

use G96 does not freeze in cold weather

use G96 does not freeze in cold weatherSimilar threads

- Replies

- 10

- Views

- 792