- Joined

- Nov 26, 2005

- Messages

- 5,010

- Reaction score

- 9,945

Hi,

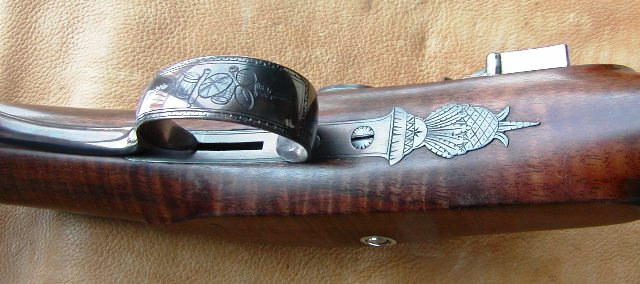

Another method used to color metal was charcoal bluing, which is basically packing the parts in charcoal and heating to about 800 degrees for 2-3 hours. There is a bit more to it than that but those are the essentials. Below are parts for a late flint era English rifle. The engraving style is from that period.

dave

Another method used to color metal was charcoal bluing, which is basically packing the parts in charcoal and heating to about 800 degrees for 2-3 hours. There is a bit more to it than that but those are the essentials. Below are parts for a late flint era English rifle. The engraving style is from that period.

dave