OldNo7

36 Cal.

Long-time percussion shooter here, getting back into the trial & tribulations with a flintlock after a couple of years hiatus...

Believing that there is "No such thing as a stupid question other than the one 'not' asked...", I'll put this question out there for replies, as I'm thinking the experiences and insights shared may be helpful to others too.

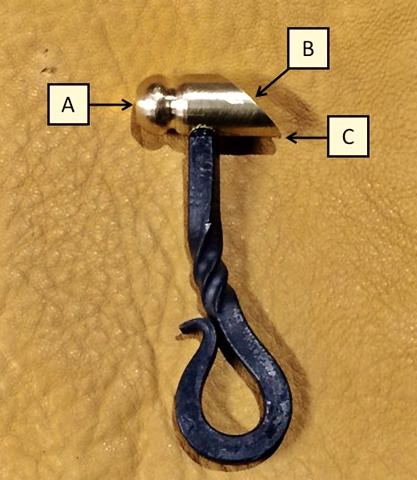

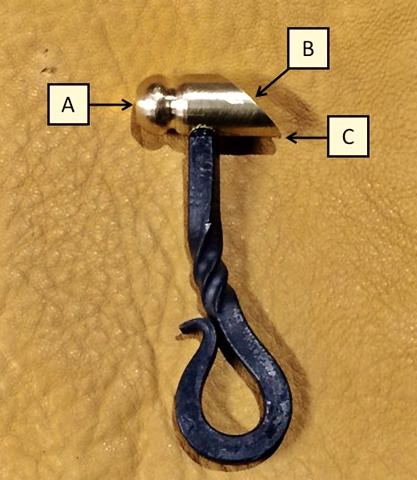

See the image posted below...

Q: "Which" face or edge of the Knapping Hammer is the correct one to use?

Or, does that depend... If so, on what?

I've viewed several knapping-related videos online, but I haven't see any close-up details that answered my question...

I am aware these are other tools to use too -- the edge of the frizzen, a brass rod, a steel nail with ground-down (smaller diameter) tip, or some type of copper pressure tool. I'd also be interested in comments about those, but I'd sure appreciate some responses about this small knapping hammer that I just acquired.

Thanks in advance for your help!

Old No7

Believing that there is "No such thing as a stupid question other than the one 'not' asked...", I'll put this question out there for replies, as I'm thinking the experiences and insights shared may be helpful to others too.

See the image posted below...

Q: "Which" face or edge of the Knapping Hammer is the correct one to use?

Or, does that depend... If so, on what?

I've viewed several knapping-related videos online, but I haven't see any close-up details that answered my question...

I am aware these are other tools to use too -- the edge of the frizzen, a brass rod, a steel nail with ground-down (smaller diameter) tip, or some type of copper pressure tool. I'd also be interested in comments about those, but I'd sure appreciate some responses about this small knapping hammer that I just acquired.

Thanks in advance for your help!

Old No7