Yes it is stamped 13 bore but like a 11 bore they are classed has 12 bore loadIt's a 13-gauge.

Feltwad

Yes it is stamped 13 bore but like a 11 bore they are classed has 12 bore loadIt's a 13-gauge.

I ran my bore scope down before shooting and was actually surprised how good it looked. I've seen plenty of older smokeless single shot shotguns severely pitted.Same advice, if the barrels ring, put a small single cell flashlight or similar down the barrels and look for huge pits, if there are none, get to shooting.

The gap between the breech plugs is larger than most but they are independent of each other.

I did not know that. Now I do.The English-made sporting gun with metric threads has yet to be made. You may have noticed that shotgun barrels are in gauges of so many spherical shot to the pound - 12 gauge [aka 12 bore] is the measure here, not 18mm or thereabouts.

A token nod to the metric system suffices here in UK, and even the government of the day gave up trying to fully metricate the UK back in the 80's. We use miles and yards for distances here, except for Wales, which uses Milltir and Llathau. We do miles per gallon, too, seeing no sense in measuring how many litres it requires for us to travel a metric distance, when our distances are measured in miles.

Bows have draw weights in pounds, and arrows are measured in inches. Powder is measured in grains, as are bullets, and velocities in feet per second. Flying is measured in MPH and so many feet above ground or sea level - and tides are measured in feet, as are winds.

You get the idea, I hope.

The barrels actually say laminated steel although I always thought that was the same as damascus but could be wrongDear All - please don't confuse 'Damascus' barrels with 'fine twist' barrels - they are quite different in manufacture.

Damascus Barrels - Barrel tubes built up by twisting alternate strips of iron and steel around a fixed rod (mandrel) and forge-welding them together in varying combinations according to the intended quality and the skill of the maker. The rod was withdrawn, the interior reamed and the exterior draw-filed until the finished tube was achieved. Damascus barrels may be recognized by any of a variety of twist or spiral patterns visible in the surface of the steel. Before the 20th century, barrels were typically built in this manner because gunmakers did not have the technology to drill a deep hole the full length of a bar of steel without coming out the side. Generally superseded a century ago by fluid steel barrels.

Damascus barrels were usually intended for use with black powder---the standard of the day. The contour of the barrel wall thickness, intended for the fast explosion of black powder, was quite thick at the breech and tapered thinner towards the muzzle. It is not advisable to shoot modern smokeless powder in a damascus barrel. Apart from giving due deference to the age of such barrels and to the method of their construction, smokeless powder burns more slowly, lowering the pressure at the breech end, but considerably raising it further down the barrel to a level such barrels were rarely designed to handle.

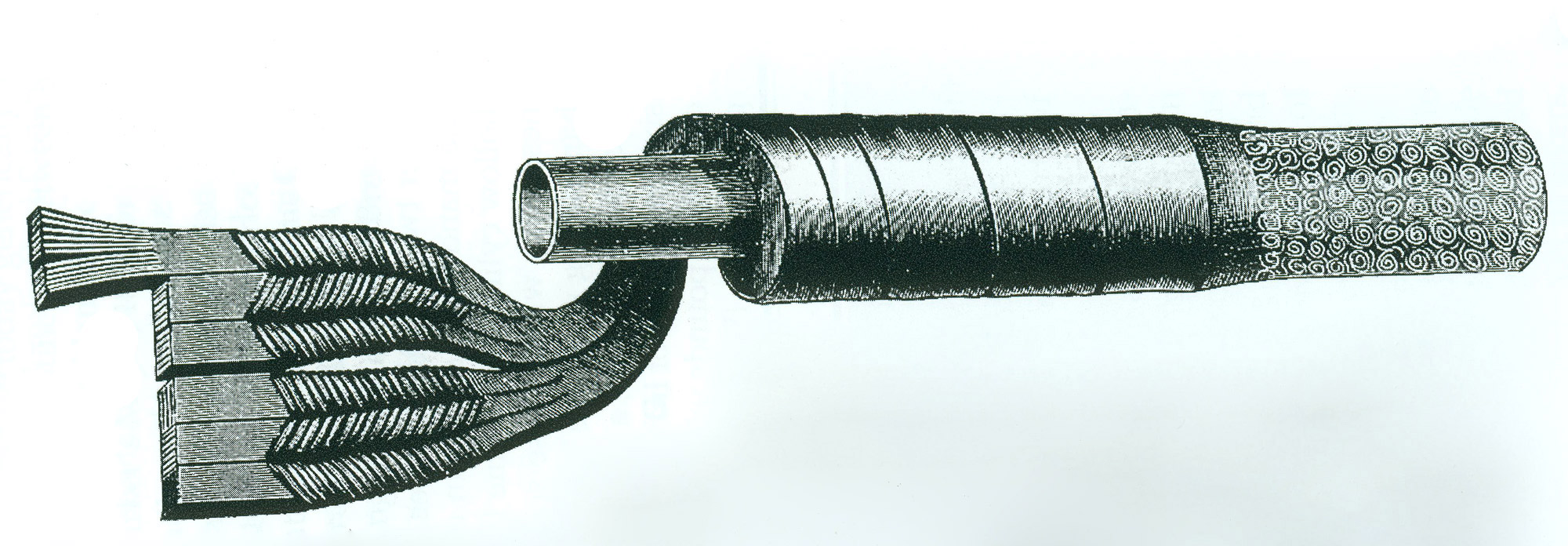

A demonstration forging, showing the steps undertaken to construct a barrel tube of damascus steel. In this case, three bars, usually of different alloys, independently twisted, then forge-welded together at a bright yellow heat into a single continuous flat bar, then wrapped around a mandrel and further forge-welded into a solid spiral. From Richard Akehurst, Game Guns & Rifles, G. Bell & Sons, London, 1969.

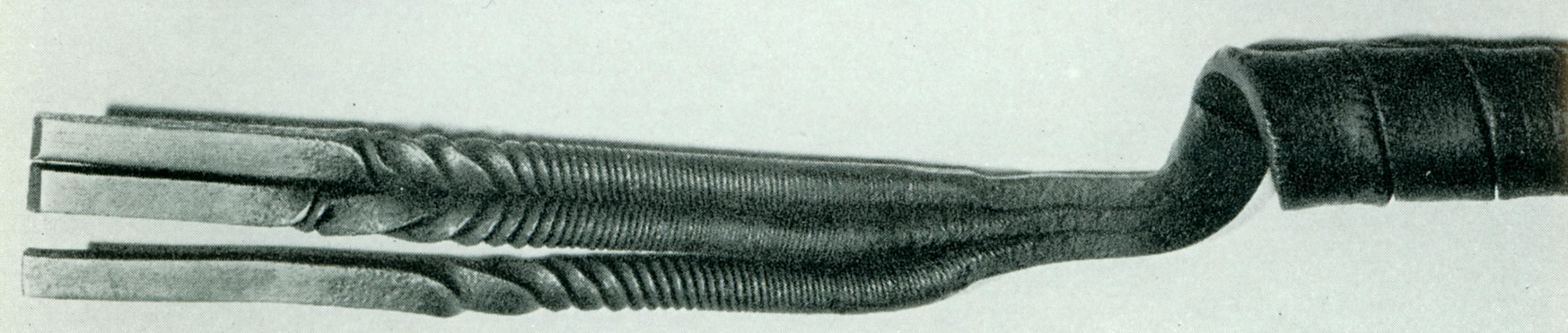

And, finally, bored out inside, drawfiled outside to requisite thinness, and finished to enhance the forged pattern.

I'm sure that Feltwad or Old Dog will come by dreckly and explain all this to you.

Yep I have been and one of mine really patterns great out to about 35 yards. Be working on others next few weeks. Have 1/4" and plenty of thin overshot cards. Also made a punch and experimenting with card board best seems to be free boxes you can get at post office to ship stuff. ThanksTrans Yank, Unfortunately there’s never a perfect answer. A 11ga 12 and a 13 I have needs a thick card 1/5 in fiber wad and then a thin card. My other 5 I use Ox Yoke wonder wads. Two over powder and one over shot. Makes for easier and faster reloading. Pattern your gun and find out what it needs. The back side of X mas paper is white usually 32in wide and broken up into one in. squares. Perfect for patterning.

Doc,

Enter your email address to join: