I think composing this missive has pretty much helped me make up my mind, but here goes.

I wanted a flintlock pistol for target shooting 'competition'. I got a good (?) deal on a Pedersoli flintlock Kentucky Pistol in .45.

Pro: I like the looks, it hangs well in my hand and the barrel looks promising.

Con: The lock is not inletted deeply enough. There is about a 1/16" gap between the lock and the barrel so a lot of the prime ends up burning in the action. It's strange to put it back in the pistol stand after firing and see smoke coming out around the trigger instead of out of the barrel!

The trigger is sort of heavy at about 8 1/2 pounds and variable by at least 1/2 pound.

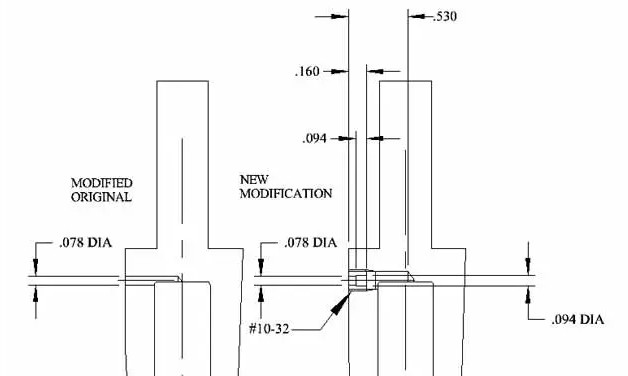

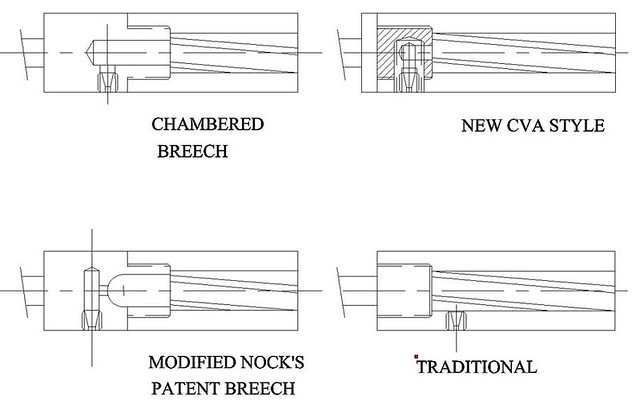

The ante-chamber (patent breech?) is giving me fits. I thought I had mastered cleaning and maintaining the ante-chamber on my Investarms Hawken, but this one is defying me. Powder bridges at the ante-chamber and doesn't reach the vent. When this happens I can stick my vent pick in and wiggle it around without feeling any powder.

The lock is hard on flints. I'm lucky to get three consecutive shots out of a flint before it needs dressed or replaced. An experienced shooter thinks this may be because the frizzen spring is unnecessarily heavy as well as the mainspring.

So...

I could probably re-inlet the lock. At 1/16" I suppose I would also have to reduce the exterior width of the stock, too and then have to refinish it. Ugh! I didn't intend to buy a kit.

Maybe I could fit a single-set trigger to this pistol? I haven't found a drop-in replacement but I did handle another identical Pedersoli pistol with a nice set trigger so something must be adaptable. But again, I intended to buy a pistol, not build one.

On the other hand, maybe the correct approach would be to rework the lock, polish it, thin the frizzen spring and mainspring. I wouldn't want to attempt this unless I had replacements already in hand. Looking into replacement parts I find these springs may be relatively expensive. Maybe an RPL lock? I haven't found one listed specifically for this pistol but maybe one is adaptable?

Stock work, trigger work, lock work and I'd still be stuck with that problematical ante-chamber. Maybe I could adapt my loading procedure to include swabbing the ante-chamber at each shot. Maybe I could relieve, smooth, cone the ante-chamber?

It's starting to seem like I am endeavoring to make a silk purse out of a sow's ear. Maybe I should see what I can get for this pistol, add the money that would be spent on a trigger, springs, or replacement lock and buy a custom pistol? I don't know. I hate to see any gun left an orphan that could benefit from some TLC, but I've already lost out on having a reliable pistol to compete with this season and I don't have a lot of time on my hands to putz with it.

Am I missing some simpler/cheaper solutions or exaggerating the necessary effort to straighten this pistol out?

Thumbs up or thumbs down? Cut my losses and kick it to the curb or persevere and enjoy a sense of accomplishment when (if) I straighten it out?

I wanted a flintlock pistol for target shooting 'competition'. I got a good (?) deal on a Pedersoli flintlock Kentucky Pistol in .45.

Pro: I like the looks, it hangs well in my hand and the barrel looks promising.

Con: The lock is not inletted deeply enough. There is about a 1/16" gap between the lock and the barrel so a lot of the prime ends up burning in the action. It's strange to put it back in the pistol stand after firing and see smoke coming out around the trigger instead of out of the barrel!

The trigger is sort of heavy at about 8 1/2 pounds and variable by at least 1/2 pound.

The ante-chamber (patent breech?) is giving me fits. I thought I had mastered cleaning and maintaining the ante-chamber on my Investarms Hawken, but this one is defying me. Powder bridges at the ante-chamber and doesn't reach the vent. When this happens I can stick my vent pick in and wiggle it around without feeling any powder.

The lock is hard on flints. I'm lucky to get three consecutive shots out of a flint before it needs dressed or replaced. An experienced shooter thinks this may be because the frizzen spring is unnecessarily heavy as well as the mainspring.

So...

I could probably re-inlet the lock. At 1/16" I suppose I would also have to reduce the exterior width of the stock, too and then have to refinish it. Ugh! I didn't intend to buy a kit.

Maybe I could fit a single-set trigger to this pistol? I haven't found a drop-in replacement but I did handle another identical Pedersoli pistol with a nice set trigger so something must be adaptable. But again, I intended to buy a pistol, not build one.

On the other hand, maybe the correct approach would be to rework the lock, polish it, thin the frizzen spring and mainspring. I wouldn't want to attempt this unless I had replacements already in hand. Looking into replacement parts I find these springs may be relatively expensive. Maybe an RPL lock? I haven't found one listed specifically for this pistol but maybe one is adaptable?

Stock work, trigger work, lock work and I'd still be stuck with that problematical ante-chamber. Maybe I could adapt my loading procedure to include swabbing the ante-chamber at each shot. Maybe I could relieve, smooth, cone the ante-chamber?

It's starting to seem like I am endeavoring to make a silk purse out of a sow's ear. Maybe I should see what I can get for this pistol, add the money that would be spent on a trigger, springs, or replacement lock and buy a custom pistol? I don't know. I hate to see any gun left an orphan that could benefit from some TLC, but I've already lost out on having a reliable pistol to compete with this season and I don't have a lot of time on my hands to putz with it.

Am I missing some simpler/cheaper solutions or exaggerating the necessary effort to straighten this pistol out?

Thumbs up or thumbs down? Cut my losses and kick it to the curb or persevere and enjoy a sense of accomplishment when (if) I straighten it out?