Rodwha,

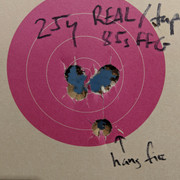

There are probably 50+ threads about using Lee R.E.A.L. slugs on this site. I believe that folks who can't get them to shoot well is mostly due to not producing quality castings and not being willing to work up a load. I have great success with ALL the Lee REAL bullets in .45, .50, .54, & .58 caliber rifles, both deep groove and shallow, fast (1 in 28") and moderate (1 in 48") twist rifles. In most of my rifles, an over powder wad is required for good accuracy. Some like more lube than others. Generally, a fast twist rifle may not shoot accurately at as high velocity as one with a slower twist in the same caliber. ALL will shoot accurately at reasonable hunting velocity. I make my own hard felt wads which I load un-lubed.

I cast mine from pure lead with 1/2% tin added to get good mould fill out. I also cast at high temperature of 800 degrees controlled by electronic thermocouple. I mostly use a Lee 10 pound bottom pour pot, but dipper cast the larger ones. Crisp, properly filled out castings are essential for accuracy.

Working up a load requires adhering to scientific principles and is not rocket science. However, most shooters do not know how to change only one variable at a time and insure that only everything else stays the same. Then there those who really can't load with uniformity or shoot accurately to begin with but are quick to add their negative opinions.