This lock was on a pistol I bought several years ago. Never fired it, the lock "sort of" worked, always dragged.

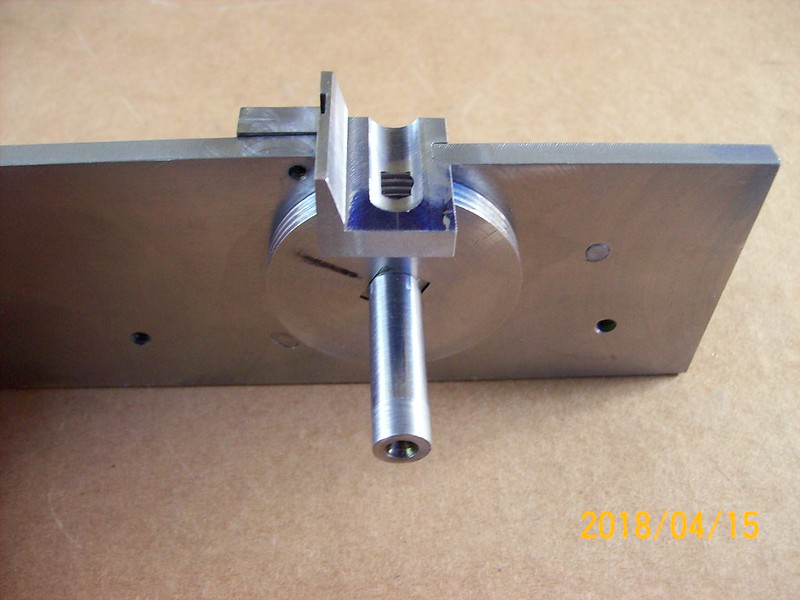

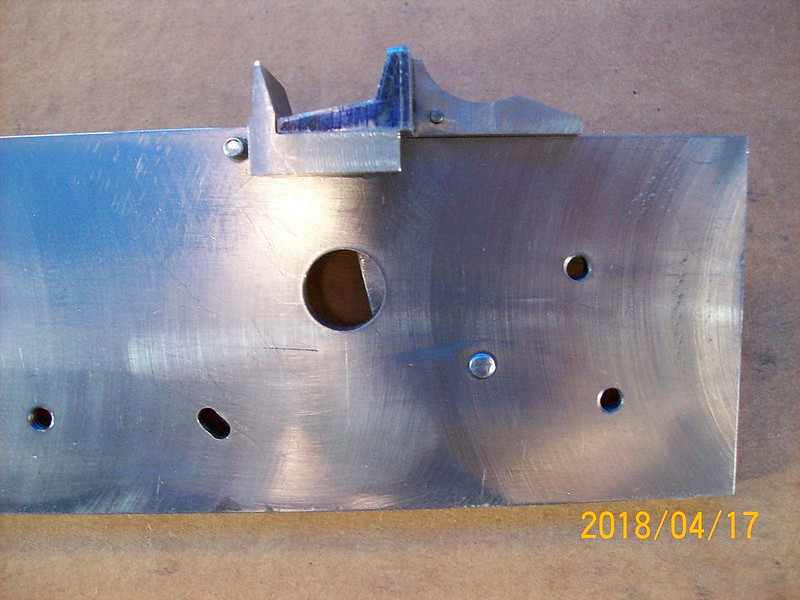

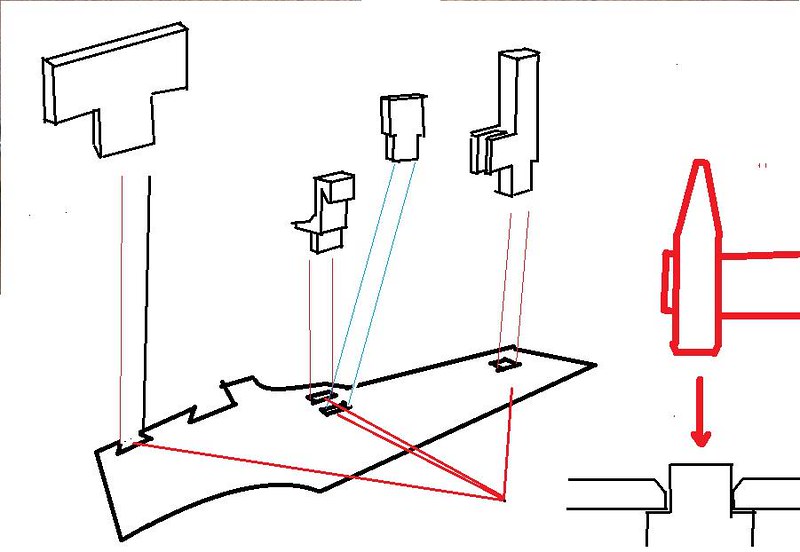

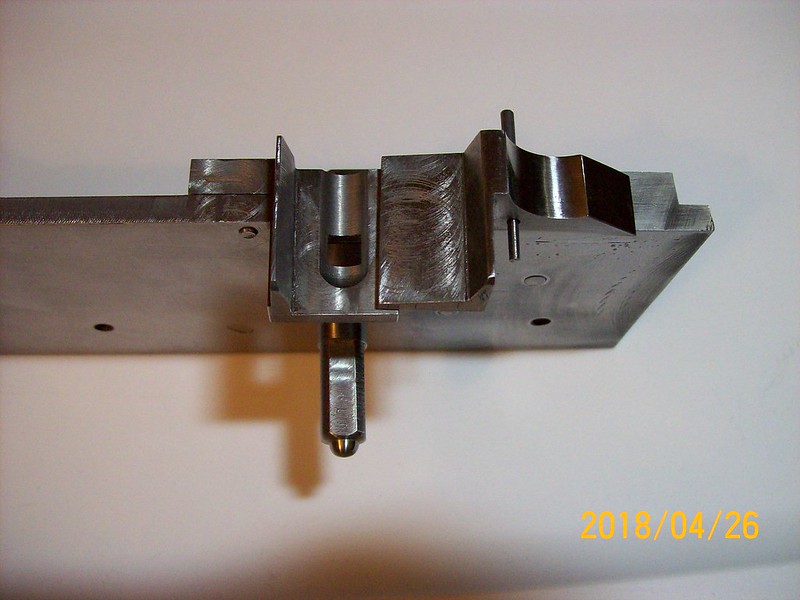

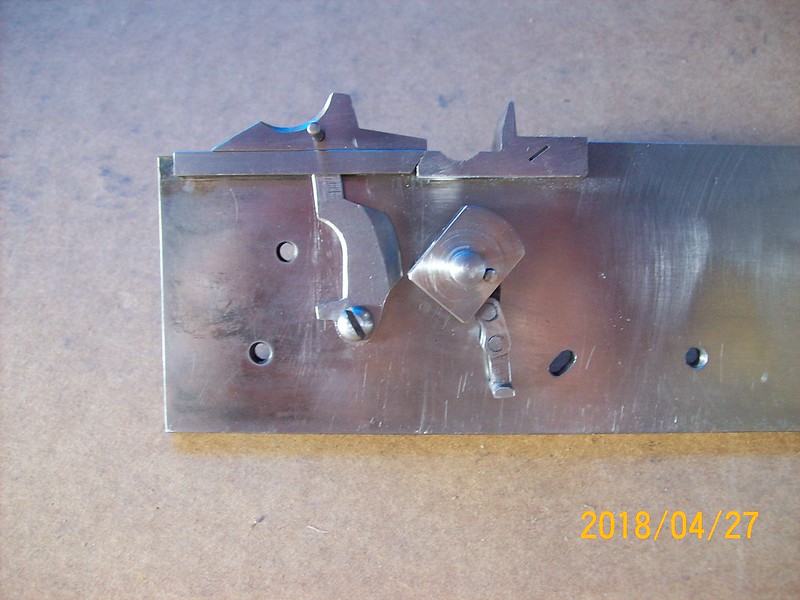

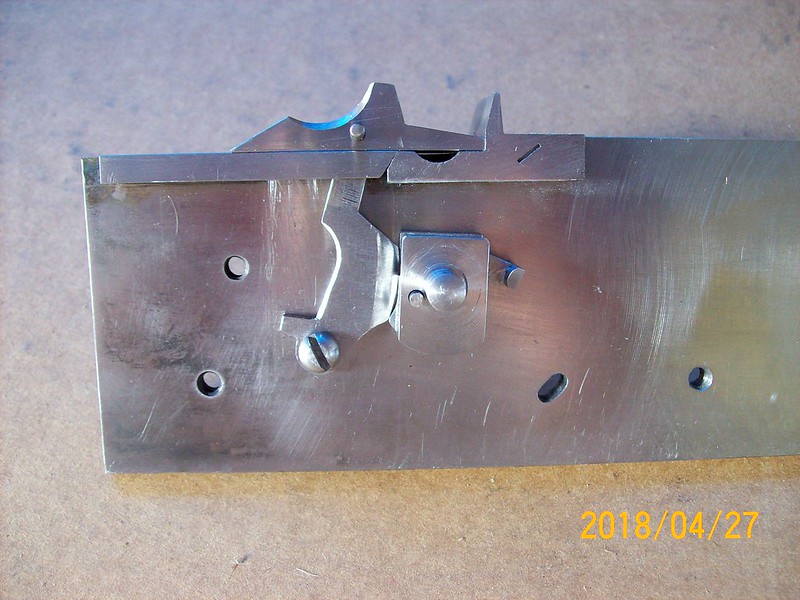

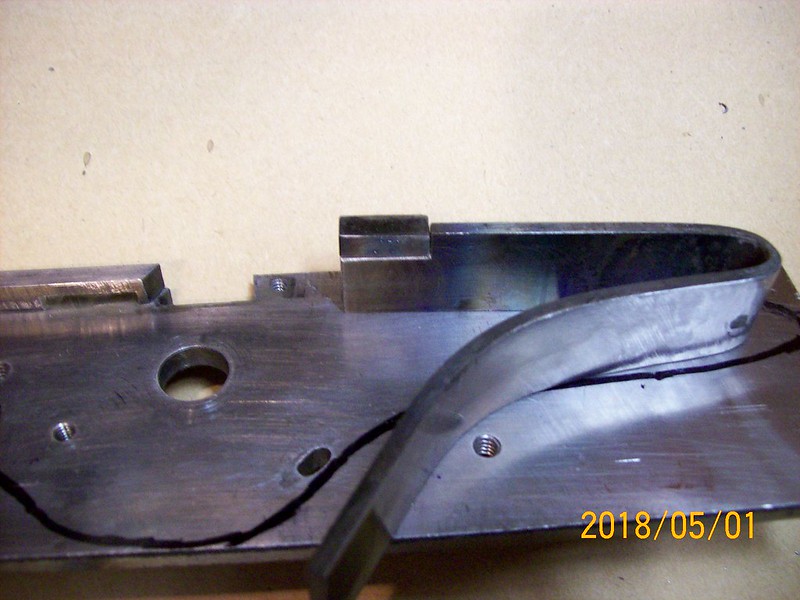

I finally thought I could machine a new tumbler shaft because the original cast piece was out of round (.407",.406", .405" & .404") & undersized and the hole in the plate was .417" diameter. Thought that was the problem. I made a new tumbler shaft to fit the existing hole and noticed the bridle always lifted also. The screw that held the bridle in place would cam the bridle up when tightened. I messed with the bridle and decided to make another and as I was still having problems with dragging and sticking. So I made another tumbler shaft with a larger diameter pivot in the lockplate. I made a replacement wheel to go with the new tumbler shaft and bridle but it was still dragging, so I finally put a steel rule on the lockplate and found that it was too screwed up to fix. So I was finished polishing that 'road apple' and will make a new plate that is flat and parallel.

The Mendi lock is much bigger than the Georg Lauber lock, in fact it has the same internal parts as The Rifle Shoppe's Dutch Musket wheellock (no. 629). The difference is the Dutch plate has a longer tail which makes it 8" long, whereas the Mendi plate is 7-1/8" long. The wheel on both is 1.75" diameter and I have laid out my parts on the photo of the Dutch lock and I can't find any difference. The wheel on the Lauber lock is 1-1/2" in diameter and the plate is 6.6" long. Since the lock is much larger than the Lauber lock, I'll probably put the rebuilt lock on a carbine.

Later, Mike

2018-03-23 15.36.09

2018-03-23 15.36.09