CaseHardened

32 Cal.

- Joined

- Feb 23, 2018

- Messages

- 33

- Reaction score

- 1

I purchased a used Pedersoli Navy Moll Flintlock recently, locally. I paid a bit over $400, and am pleased in both saving $$$ and in getting a Used Firearm.

Although everyone loves NEW, I am reluctant to fire a new gun. It devalues them so much ! (yeah, a bit silly, I suppose)

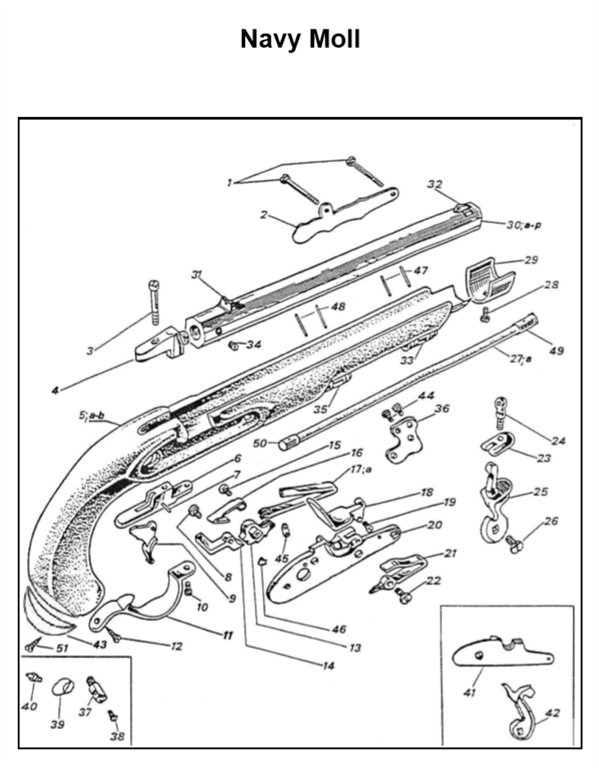

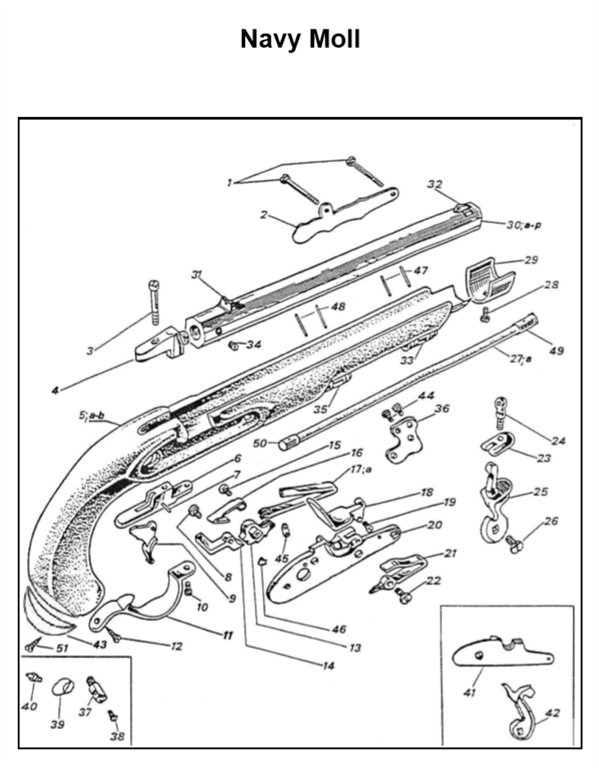

Other than considerable wear to the face of the Frizzen (18), it appears as new.

I've not fired it yet, myself, and wish to be fully informed before I do.

This is my first Flintlock, and I initially did not realize I needed to remove the Barrel (30) and Vent Insert (34) to clean this properly.

I acquired some GRACE Screwdrivers, identified the ones that fit perfectly (G3, H2, N2), and removed the Barrel and Vent Insert with no issue.

But I was surprised to see the full Bore does not extend thru to the Vent Insert, but stops just forward of it. Leaving a much smaller hole that does extend to the Vent Insert.

How can I clean this small internal area properly ?

Should I, can I remove the Breech Plug (04) ?

Is it necessary to do even further disassembly ?

I also noticed the Stock (5), in the normally hidden area that the Barrel fits into, is unfinished.

Should I Wax it ? Shellac it ? Leave it Raw ?

And as an observation, which others have made, the Fore End Cap Screw (28) is really tiny. I suppose Pedersoli knows more than me, but its diminutive size is not reassuring.

Although everyone loves NEW, I am reluctant to fire a new gun. It devalues them so much ! (yeah, a bit silly, I suppose)

Other than considerable wear to the face of the Frizzen (18), it appears as new.

I've not fired it yet, myself, and wish to be fully informed before I do.

This is my first Flintlock, and I initially did not realize I needed to remove the Barrel (30) and Vent Insert (34) to clean this properly.

I acquired some GRACE Screwdrivers, identified the ones that fit perfectly (G3, H2, N2), and removed the Barrel and Vent Insert with no issue.

But I was surprised to see the full Bore does not extend thru to the Vent Insert, but stops just forward of it. Leaving a much smaller hole that does extend to the Vent Insert.

How can I clean this small internal area properly ?

Should I, can I remove the Breech Plug (04) ?

Is it necessary to do even further disassembly ?

I also noticed the Stock (5), in the normally hidden area that the Barrel fits into, is unfinished.

Should I Wax it ? Shellac it ? Leave it Raw ?

And as an observation, which others have made, the Fore End Cap Screw (28) is really tiny. I suppose Pedersoli knows more than me, but its diminutive size is not reassuring.