After a few years of playing around I finally got around to slugging the barrels and throats on my 1858s (Pietta). I was pretty surprised at the results. Granted, they're pretty hard to measure accurately due to the odd number of grooves, but I believe I did a reasonably accurate job.

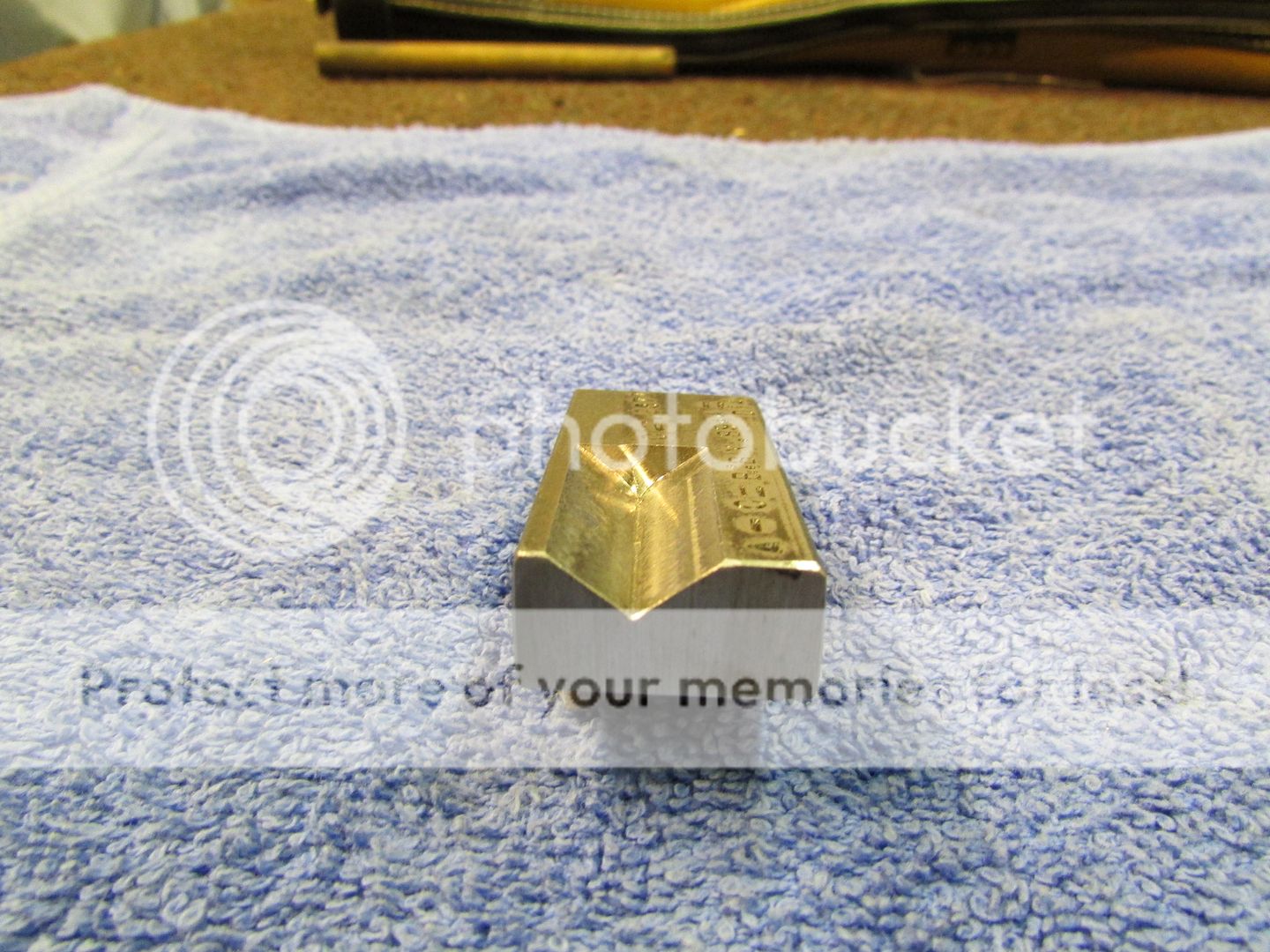

First I slugged the barrel with a .457 ball. I noticed right away it was pretty easy and the resulting ball didn't reach to the bottom of the grooves. I took another whack with a .490 ball. The resulting measurement was .460". Wowzers.

Next I did the cylinder with a .454 ball. The ball came out to a swaged/shaved .448". I checked a second cylinder and it was very close.

Third, I took the .458 cylinder slug and pushed it through the barrel. It pushed through by hand leaving barely noticeable rifling marks.

Finally, I pushed the barrel slug halfway into a cylinder. It all but removed the rifling.

My land diameter is a carefully calculated guess, but here's what I am getting:

Grooves: .460"

Lands: .446"

Throat: .448"

As final observation, both barrels are tight at the frame threads.

Well, that leaves me pretty well stuck as far as improvements. I'd hoped to ream the cylinder to .001 over groove diameter, but I'm not terribly excited about reaming it to .461.

At the same time I have only .001" rifling engagement! How sad is that?

Any thoughts on reaming cylinders to .4525? It would increase my rifling engagement by a couple thousandths, but still leave me several thousandths under groove diameter. Not sure if I'm solving anything with that approach.

First I slugged the barrel with a .457 ball. I noticed right away it was pretty easy and the resulting ball didn't reach to the bottom of the grooves. I took another whack with a .490 ball. The resulting measurement was .460". Wowzers.

Next I did the cylinder with a .454 ball. The ball came out to a swaged/shaved .448". I checked a second cylinder and it was very close.

Third, I took the .458 cylinder slug and pushed it through the barrel. It pushed through by hand leaving barely noticeable rifling marks.

Finally, I pushed the barrel slug halfway into a cylinder. It all but removed the rifling.

My land diameter is a carefully calculated guess, but here's what I am getting:

Grooves: .460"

Lands: .446"

Throat: .448"

As final observation, both barrels are tight at the frame threads.

Well, that leaves me pretty well stuck as far as improvements. I'd hoped to ream the cylinder to .001 over groove diameter, but I'm not terribly excited about reaming it to .461.

At the same time I have only .001" rifling engagement! How sad is that?

Any thoughts on reaming cylinders to .4525? It would increase my rifling engagement by a couple thousandths, but still leave me several thousandths under groove diameter. Not sure if I'm solving anything with that approach.