Using leather strips to wrap through the ramrod pipes will hold the ramrod in the stock, and also muffle any "rattle" against a barrel, or half-rib.

I once saw a re-enactor use latigo Boot laces to wrap around his forward ramrod pipe on his Bess, and it kept the steel rod from both rattling, and in the stock during maneuvers. I asked him why he didn't "wrap" the middle pipe on the stock, too, and he said it simply had not proven to be necessary.

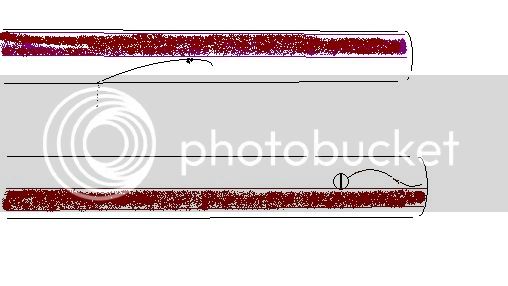

As to the Spring for these rods, I suspect its some kind of flat spring placed in the ramrod channel( probably near the entry pipe, where there is enough space to use either a rivet or small screw to secure the flat spring) to put pressure on the iron or steel ramrod and hold it in the stock.

I am surprised at this discovery, since I did not know that flat springs that are that THIN were available in the 18th century. We are used to thinking of this kind of thing being a product of rolled steel plates, not something that would have been forged by a blacksmith/gunsmith using an anvil and hammer. Obviously, when I think back the springs used in Wheellock actions, such thin spring stock was available long before the 18th century. How it was made is another matter.

These items may exist by the hundreds in original guns now in Museum collections. However, getting any museum Curator to actually let you take these guns apart to find out what might be in the gun that cannot be readily seen, is NEXT TO IMPOSSIBLE, no matter who you are.

:nono: :surrender: :hatsoff: