123.DieselBenz

45 Cal.

- Joined

- Feb 5, 2010

- Messages

- 706

- Reaction score

- 0

Howdy!

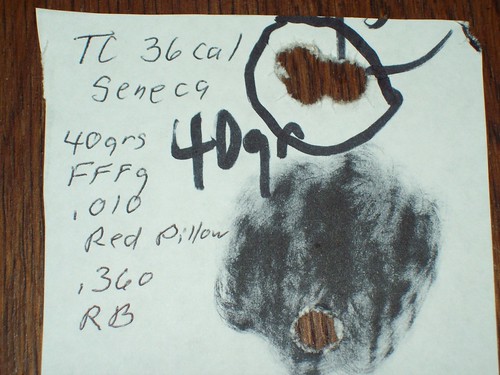

I finally got to take my new to me T/C Seneca out and make smoke with it this afternoon!

I'm not a very good shot, but I still had fun . . .

I tried a bunch of different loads and patches, so I don't have anything definite worked out yet, other that it's FUN!

I ended up shooting 25 rounds through it! This target I ended up using some old prelubed .01 patches around the ball, and a dry .02 patch to protect it from the load . . .

A few different loads of powder, but the same patch . . .

I do have a few questions about my patches . . . I ended up using these with spit they measure .0195" thick:

These are the few I found in the desert . . . Notice the one on the lower left . . .

Here is the other sides:

What causes the patches to fold in half? they seem to be stuck, or the edges woven together . . . this is what the one that was shown folded in half looks like:

I finally got to take my new to me T/C Seneca out and make smoke with it this afternoon!

I'm not a very good shot, but I still had fun . . .

I tried a bunch of different loads and patches, so I don't have anything definite worked out yet, other that it's FUN!

I ended up shooting 25 rounds through it! This target I ended up using some old prelubed .01 patches around the ball, and a dry .02 patch to protect it from the load . . .

A few different loads of powder, but the same patch . . .

I do have a few questions about my patches . . . I ended up using these with spit they measure .0195" thick:

These are the few I found in the desert . . . Notice the one on the lower left . . .

Here is the other sides:

What causes the patches to fold in half? they seem to be stuck, or the edges woven together . . . this is what the one that was shown folded in half looks like: