-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I need a new lock

- Thread starter sr500

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Its a little piece, that is hooked on the spring.I tried to MIG weld on a little material, but the piece got so soft that it bend when i tried the lock. Sad that i am so dumb with computers. I dont know how to put in a picture to the forum.

Dnepr, It sounds like you may have drawn the temper out of the spring by welding on it. You should be able to straighten it out and re-temper it. Good luck!

Robby

Robby

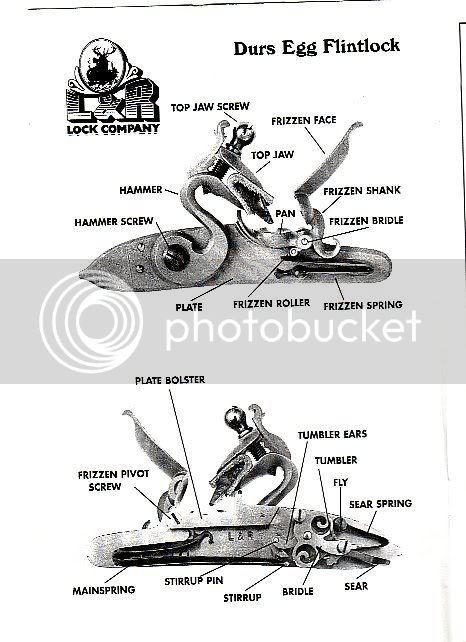

Much cheaper and easier just to replace a spring. Here's a component view

Hi guys. No it was not the spring i welded on. It was on the little piece that was hooked on the end of the spring.And that little piece was mounted on a wheel where the sear is conected when coocked. I have looked on some locks, but i have not seen any like my.

I believe you are describing the stirrup, a little piece which connects the wheel (tumbler) to the mainspring. There are pictures of it at this link:Dnepr 750 said:Hi guys. No it was not the spring i welded on. It was on the little piece that was hooked on the end of the spring.And that little piece was mounted on a wheel where the sear is conected when coocked. I have looked on some locks, but i have not seen any like my.

http://home.insightbb.com/~bspen/percterm.html

Spence

Last edited by a moderator:

Hi. Yes it sure is. Its look a little different on my lock. I was thinking if i could make one, but it have to be strong, cause the hammerspring is verry strong. I shall look in my workshop and see if i have a piece of steel that i can grind and drill to fit.Cause i dont think that i can find that piece as a sparepart. Thanks alot for your help. I realy like this forum. :v

Without a picture of the part I am doing some guessing here but the mainspring stirrup needs to be made out of a very high strength steel.

A spring steel like AISI 1090 would work if you could find any.

Another possibility that might work would be to make the part out of a Carbon Steel hack saw blade and a length of "music wire".

The hack saw blade is hardened so if you don't have access to small grinding wheels you will have to anneal it to soften it.

This can be done with a propane torch, heating the blade to a cherry red color and then allowing it to air cool. That will soften it so you can file and drill it.

The "music wire" needs to be the same diameter as the existing stirrups cross pins and it can be bought at most hobby shops or hardware stores.

You will also need a drill bit that is the same size as the music wire.

The hack saw blade may be thinner than the existing stirrup and if it is you will need to use multiple pieces of the blade to 'build' some stock that is the same thickness.

This can be done by filing off the teeth on the softened blade and then cutting the blade into 2 inch long pieces.

Use a "Super Glue" or epoxy to bond the pieces together.

Drill holes for the pins thru the blades making the distance between the holes the same as the original stirrup.

Use files to shape the exterior to match the original stirrup. Sometimes these stirrups are quite fancy in their shapes and they don't have to be but they do need to be the same size in the areas where the cross pins are located.

Once shaped you will need to harden the pieces.

To do this, you must heat them up to a bright cherry red color. When you do this, the Super glue or epoxy will evaporate but don't worry about it.

When the parts are bright cherry red, rapidly dump them into a glass of water. This will harden them. To check for hardness try filing one of them. The file should not be able to cut into the metal.

Remove any scale that may have formed on the now, hardened parts.

Cut the music wire to a length similar to the existing stirrups cross pins. A little longer is better than to short.

This music wire is quite hard and grinding it to length may be required. If you do grind it, cool it often because you do not want to the wire to get too hot.

Once the wire is cut to length you should be able to "stack" the new stirrups onto the two new pins. When doing this, coat the surfaces between the new stirrups with a paste soldering flux.

Now, making sure the blades are tightly fit together and holding them with a pair of needle nosed pliers SLOWLY heat them with a propane torch, keeping them at least 2 inches from the tip of the flame.

Apply some soft solder (lead/tin) to the parts repeatedly until the solder starts to melt.

Allow the solder to penetrate the areas between the blades and allow the assembly to air cool.

After filing off the excess solder you should have a new stirrup that will fix your lock.

A spring steel like AISI 1090 would work if you could find any.

Another possibility that might work would be to make the part out of a Carbon Steel hack saw blade and a length of "music wire".

The hack saw blade is hardened so if you don't have access to small grinding wheels you will have to anneal it to soften it.

This can be done with a propane torch, heating the blade to a cherry red color and then allowing it to air cool. That will soften it so you can file and drill it.

The "music wire" needs to be the same diameter as the existing stirrups cross pins and it can be bought at most hobby shops or hardware stores.

You will also need a drill bit that is the same size as the music wire.

The hack saw blade may be thinner than the existing stirrup and if it is you will need to use multiple pieces of the blade to 'build' some stock that is the same thickness.

This can be done by filing off the teeth on the softened blade and then cutting the blade into 2 inch long pieces.

Use a "Super Glue" or epoxy to bond the pieces together.

Drill holes for the pins thru the blades making the distance between the holes the same as the original stirrup.

Use files to shape the exterior to match the original stirrup. Sometimes these stirrups are quite fancy in their shapes and they don't have to be but they do need to be the same size in the areas where the cross pins are located.

Once shaped you will need to harden the pieces.

To do this, you must heat them up to a bright cherry red color. When you do this, the Super glue or epoxy will evaporate but don't worry about it.

When the parts are bright cherry red, rapidly dump them into a glass of water. This will harden them. To check for hardness try filing one of them. The file should not be able to cut into the metal.

Remove any scale that may have formed on the now, hardened parts.

Cut the music wire to a length similar to the existing stirrups cross pins. A little longer is better than to short.

This music wire is quite hard and grinding it to length may be required. If you do grind it, cool it often because you do not want to the wire to get too hot.

Once the wire is cut to length you should be able to "stack" the new stirrups onto the two new pins. When doing this, coat the surfaces between the new stirrups with a paste soldering flux.

Now, making sure the blades are tightly fit together and holding them with a pair of needle nosed pliers SLOWLY heat them with a propane torch, keeping them at least 2 inches from the tip of the flame.

Apply some soft solder (lead/tin) to the parts repeatedly until the solder starts to melt.

Allow the solder to penetrate the areas between the blades and allow the assembly to air cool.

After filing off the excess solder you should have a new stirrup that will fix your lock.

Tommy, here's a different picture of one, probably not like yours, either, but a little easier to see.Dnepr 750 said:Hi. Yes it sure is. Its look a little different on my lock.

Spence

Blackleys or Dyson might have that part.

http://www.peterdyson.co.uk/

http://www.blackleyandson.com/

God bless

http://www.peterdyson.co.uk/

http://www.blackleyandson.com/

God bless

Last edited by a moderator:

I believe that L&R has changed the design of that stirrup.

Notice the depression on the tumbler for the stirrup. http://www.trackofthewolf.com/Cate...14&subId=148&styleId=827&partNum=LOCK-LR-1100

The Davis lock, however, has the old style stirrup.

http://www.trackofthewolf.com/Cate...Id=14&subId=148&styleId=832&partNum=LOCK-LK-F

Click on "view two"in the top, left corner of the screen to see the internals of the locks.

God bless

Notice the depression on the tumbler for the stirrup. http://www.trackofthewolf.com/Cate...14&subId=148&styleId=827&partNum=LOCK-LR-1100

The Davis lock, however, has the old style stirrup.

http://www.trackofthewolf.com/Cate...Id=14&subId=148&styleId=832&partNum=LOCK-LK-F

Click on "view two"in the top, left corner of the screen to see the internals of the locks.

God bless

Last edited by a moderator:

Yes. Piano wire is the same thing.

The wire in the U.S. can be bought in straight 36 inch lengths for very little money.

This hardened wire is also used by builders of Model Airplanes (aeroplanes?) to use as landing gear and pushrods.

The wire in the U.S. can be bought in straight 36 inch lengths for very little money.

This hardened wire is also used by builders of Model Airplanes (aeroplanes?) to use as landing gear and pushrods.

Similar threads

- Replies

- 7

- Views

- 304