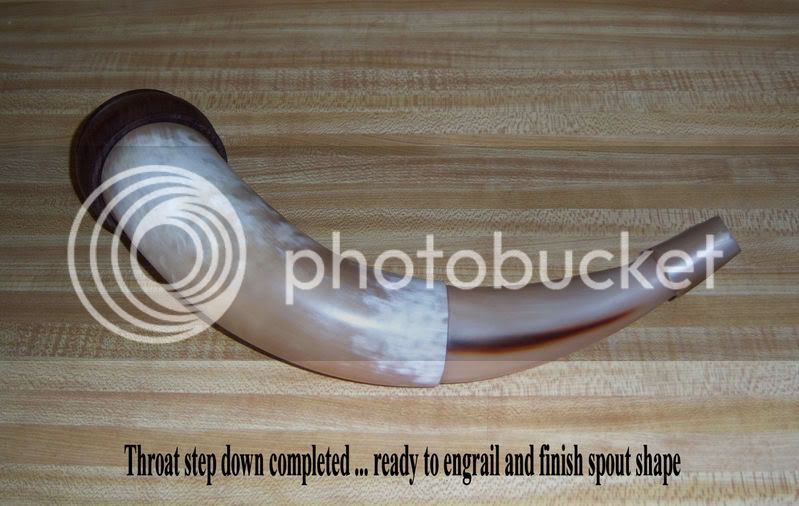

Here's a horn I got at the DayLilly Wine Festival this summer. There was a company there that uses horns as organic mulch after burying them in the ground and letting them decompose. He had this horn on his table and I asked what he wanted for it. He said they "usually sell them for $15.00" and I said that was too much for what I wanted to give to try to make a powder horn. He thought a minute and tossed it to me, telling me I could have it. He said they get barrels of horns every day to bury. I told him I'd like to visit and pick through their horns. He invited me down and said "anytime", but they would charge me. Now I have to find that brochure. If I could get a dozen good horns, it would be worth the visit. We'll see. Here is the horn in process so far. My wife gave me an old Asparagus cooker for the shop. Thanks for looking.

Ron

Ron