John Taylor

45 Cal.

- Joined

- Oct 31, 2005

- Messages

- 776

- Reaction score

- 3

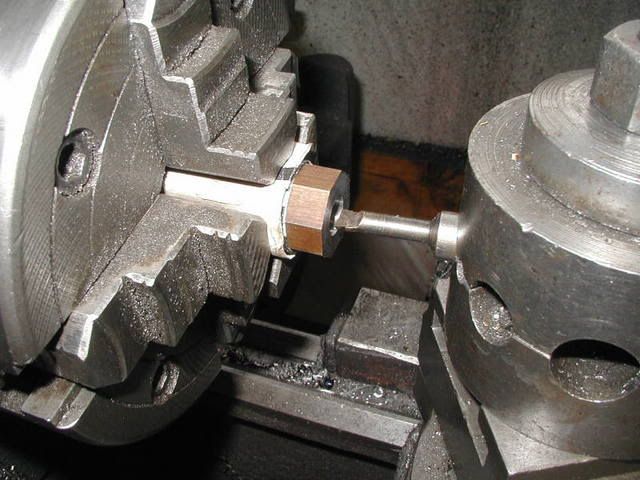

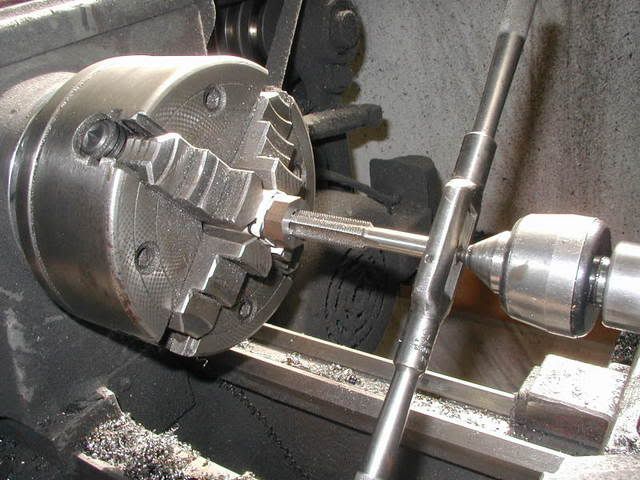

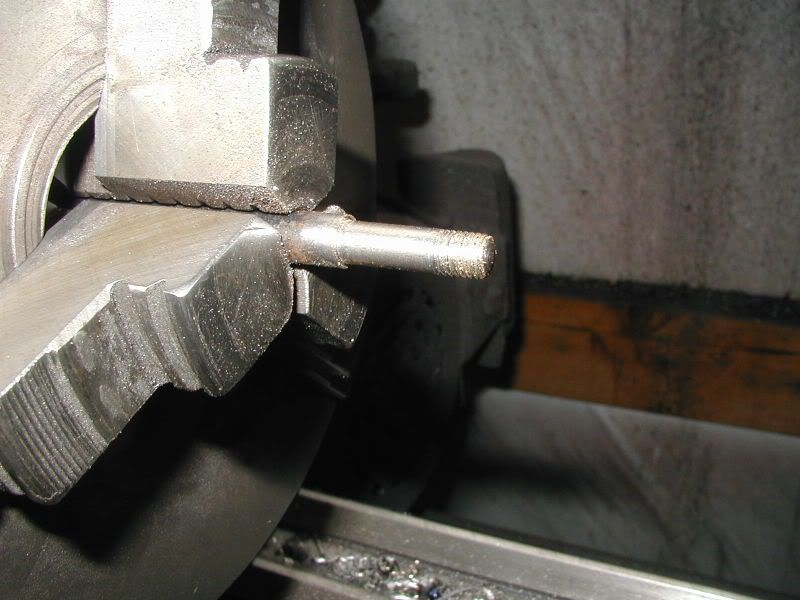

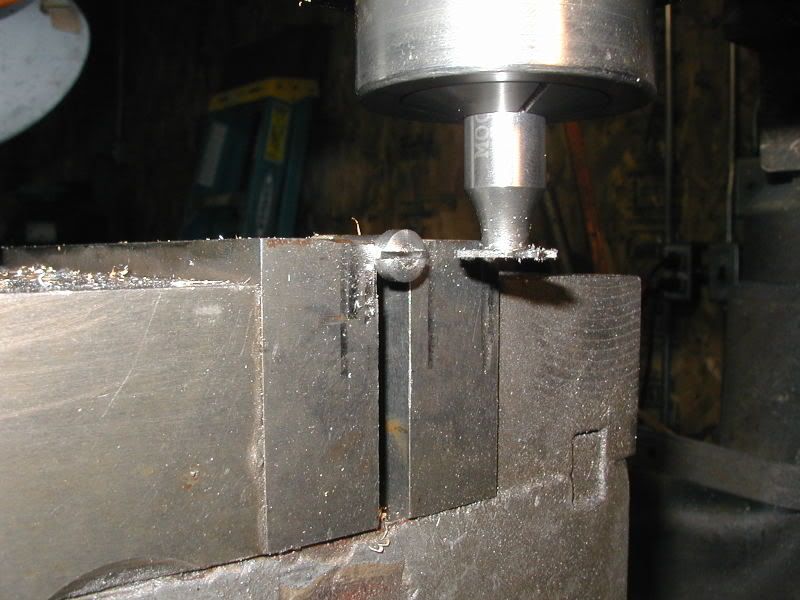

Have been thinking about this for a while. Had some 1" diameter pump shaft and thought it would make a nice little under hammer. Started by truing up both ends and reaming one end to 1/2" and threading the other end for 1/2". I put a bolt in the one end and a short piece of round stock in the other end so it would not squish when I was bending it. Then cut the groove for the hammer and trigger and drilled the holes for the screws. I'm using a hammer and trigger for an H&A just to save time.