- Joined

- Nov 26, 2005

- Messages

- 5,010

- Reaction score

- 9,945

Hi,

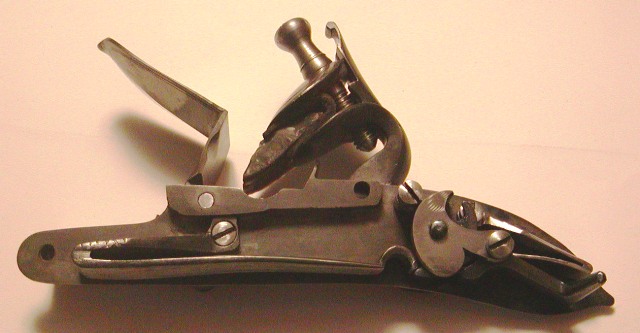

Been working on this for a while along with 3 other projects. It is a British pattern 1730 long land Brown Bess musket upgraded with double bridled lock, stronger trigger guard, and brass nose band. Those upgrades started being made very soon after the musket was first issued. I still have to finish shaping the stock including the butt and lock area as well as removing even more wood along the forearm. There are many details to attend. For example, note the lock and side panels dip down along with the shape of the lock at the tail. The bottom edge should actually be fairly straight so the dip will be removed and the edge of the lock at that point will come almost to the edge of the molding. The flat around the lock will virtually disappear. The lock still sits a little deep so the wood has to be filed flush with the edge. The swell at the rear ramrod pipe needs to be made more ball-like. I have to add the nose band and pin the trigger in place. Then the black walnut stock will be final filed and scraped, no sandpaper and the finished surface will still have a few tool marks. I'll stain the stock yellow to warm up the black walnut, then alkanet root stain to give it a bit more red. Finally, Sutherland-Welles polymerized tung oil wiping varnish. I included some photos showing a Miroku Bess stock along with this one. Note how straight the Miroku is and how short the butt plate. It is 4.75", which is 3/8" to 9/16" too short even for a short land pattern Bess and it makes a huge difference in the architecture of the gun. The Pedersoli Bess has the same problem. The early pattern Bess is the best shooter because it has the most drop in the stock and it is one of the lightest versions of the long land musket. Mine will weigh 9 lbs.

dave

Been working on this for a while along with 3 other projects. It is a British pattern 1730 long land Brown Bess musket upgraded with double bridled lock, stronger trigger guard, and brass nose band. Those upgrades started being made very soon after the musket was first issued. I still have to finish shaping the stock including the butt and lock area as well as removing even more wood along the forearm. There are many details to attend. For example, note the lock and side panels dip down along with the shape of the lock at the tail. The bottom edge should actually be fairly straight so the dip will be removed and the edge of the lock at that point will come almost to the edge of the molding. The flat around the lock will virtually disappear. The lock still sits a little deep so the wood has to be filed flush with the edge. The swell at the rear ramrod pipe needs to be made more ball-like. I have to add the nose band and pin the trigger in place. Then the black walnut stock will be final filed and scraped, no sandpaper and the finished surface will still have a few tool marks. I'll stain the stock yellow to warm up the black walnut, then alkanet root stain to give it a bit more red. Finally, Sutherland-Welles polymerized tung oil wiping varnish. I included some photos showing a Miroku Bess stock along with this one. Note how straight the Miroku is and how short the butt plate. It is 4.75", which is 3/8" to 9/16" too short even for a short land pattern Bess and it makes a huge difference in the architecture of the gun. The Pedersoli Bess has the same problem. The early pattern Bess is the best shooter because it has the most drop in the stock and it is one of the lightest versions of the long land musket. Mine will weigh 9 lbs.

dave