Doug Lykins

40 Cal.

- Joined

- Dec 28, 2008

- Messages

- 303

- Reaction score

- 1

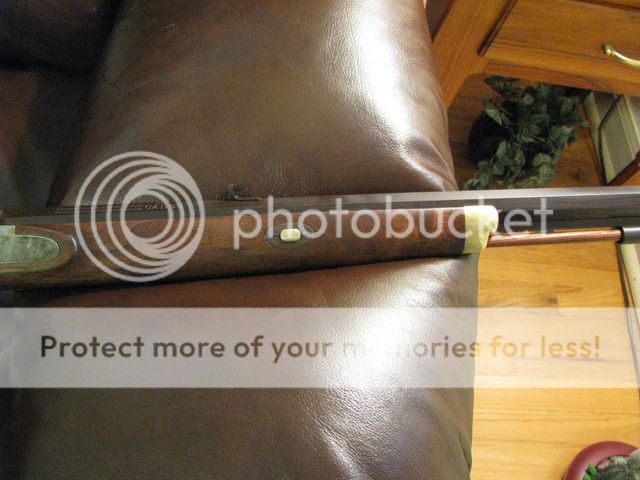

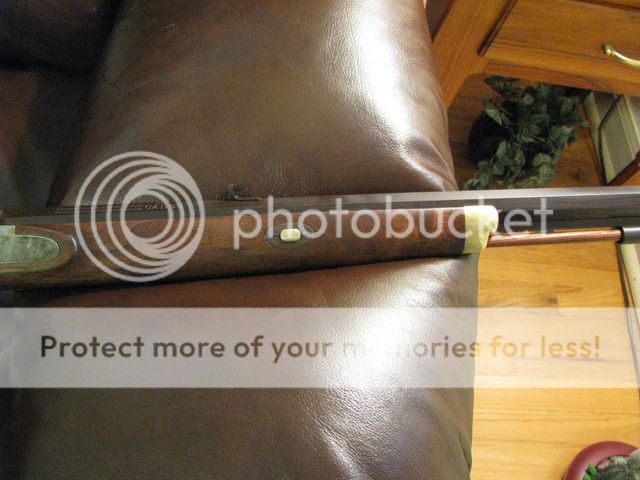

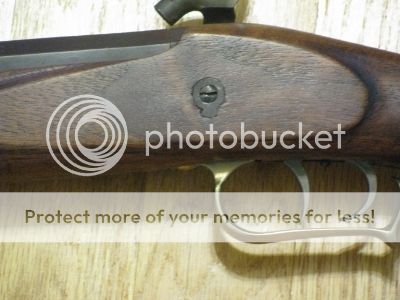

Last fall I was visiting family in Utah. Walked into a hock-shop in Provo and spotted one of the TC kits. Nothing special here, just another TC. I'm not sure when TC stopped selling the Hawken kit but the pawn shop owner had it in his shop for a long time and he was ready to negotiate. After making a deal I brought it back home to Wyoming and after a few months put her together. These are easy to do, inletting is just shy of 100% but I had to remove a bunch of wood shape the stock. To make it interesting I put a few of my own affects to the gun.

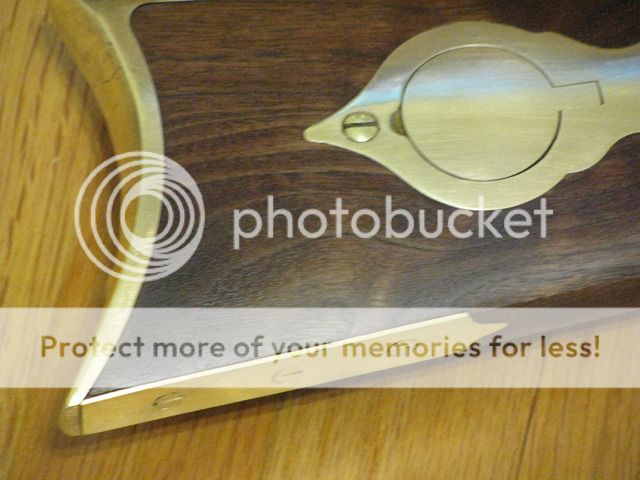

I scrapped the brass thimbles and silver soldered a couple of iron thimbles onto the under rib. I used the brass wedge key but filed a couple of iron plates to replace the brass units. I reshaped the front sight and scraped the adjustable rear sight. I plugged the screw holes, cut & filed a dovetail slot to accommodate a fixed rear sight. All rust browned obviously. I also filed about 30% of the brass nose piece away and reshaped.

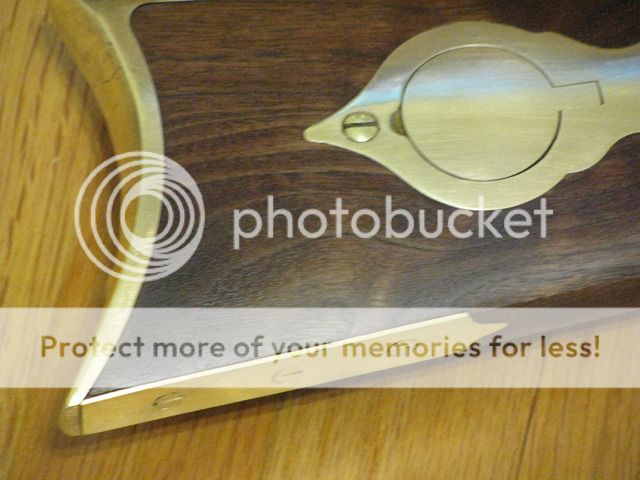

I also made a brass toe plate.

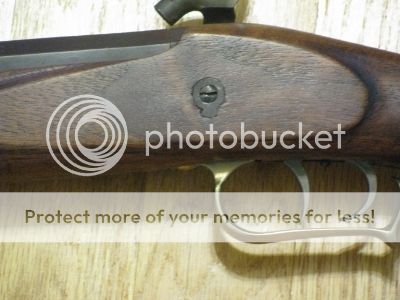

I buffed the case hardening from the lock and "antiqued" it.

I made an iron escutcheon to replace the brass unit.

What do ya think fellas?

I scrapped the brass thimbles and silver soldered a couple of iron thimbles onto the under rib. I used the brass wedge key but filed a couple of iron plates to replace the brass units. I reshaped the front sight and scraped the adjustable rear sight. I plugged the screw holes, cut & filed a dovetail slot to accommodate a fixed rear sight. All rust browned obviously. I also filed about 30% of the brass nose piece away and reshaped.

I also made a brass toe plate.

I buffed the case hardening from the lock and "antiqued" it.

I made an iron escutcheon to replace the brass unit.

What do ya think fellas?