Hi there. I was just wondering if someone would be able to tell what thickness is best suited for a loading block, and what diameter holes are best drilled in a loading block for a 50 cal. PRB? And lastly, is there such a thing as a loading block for a conical bullet? Thank you.

-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Loading Block Question

- Thread starter NEW222

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Here's an Official Loading Block Drill Bit Chart.

http://www.muzzleloadingforum.com/fusionbb/showtopic.php?tid/192279/

Last edited by a moderator:

ApprenticeBuilder

58 Cal.

- Joined

- May 27, 2006

- Messages

- 2,528

- Reaction score

- 189

- Joined

- Aug 25, 2003

- Messages

- 6,387

- Reaction score

- 1,252

I like them about 3/8" thick. That allows the ball to protrude and self align in the muzzle, and since it is a ball, there is only so much contact surface in the hole anyway.

Thats swell! Cock up! ?? :idunno:

I have a planer and make blocks just a hair thicker than the diameter of the ball. There are no set standards that I know of. Blocks for elongated projectiles most likely have existed and may still be used by some.

Sorry to be vague, but this is a 'do yer own thang' game. No real standards.

Sorry to be vague, but this is a 'do yer own thang' game. No real standards.

Brokennock

Cannon

FWIW, I prefer to make my initial hole for the ball a hair undersize and file to fit my ball/patch combo. Also I use a board slightly thicker than the diameter of the ball and use a forstner bit slightly larger than the muzzle to create a shallow flat bottomed countersink that fits the muzzle for easy positioning.

Yes, I never let a loading block rattle around in the bottom of my shot bag to gather grit and grime. I either slip it into a pocket inside the bag or tie it to a strap so it's suspended in the bag. That's why mine have a lanyard. I don't think having a thicker board will completely prevent the ball collecting grit.

I rarely use loading block at all, these days, since most of my shooting is done with a smoothbore, and many times with historic wadding, no patch.

Spence

I rarely use loading block at all, these days, since most of my shooting is done with a smoothbore, and many times with historic wadding, no patch.

Spence

ApprenticeBuilder

58 Cal.

- Joined

- May 27, 2006

- Messages

- 2,528

- Reaction score

- 189

Alden said:Problem with a thin board is the "gooey" is out there to rub on everything and for everything to get all over it. SOMEtimes that won't matter...

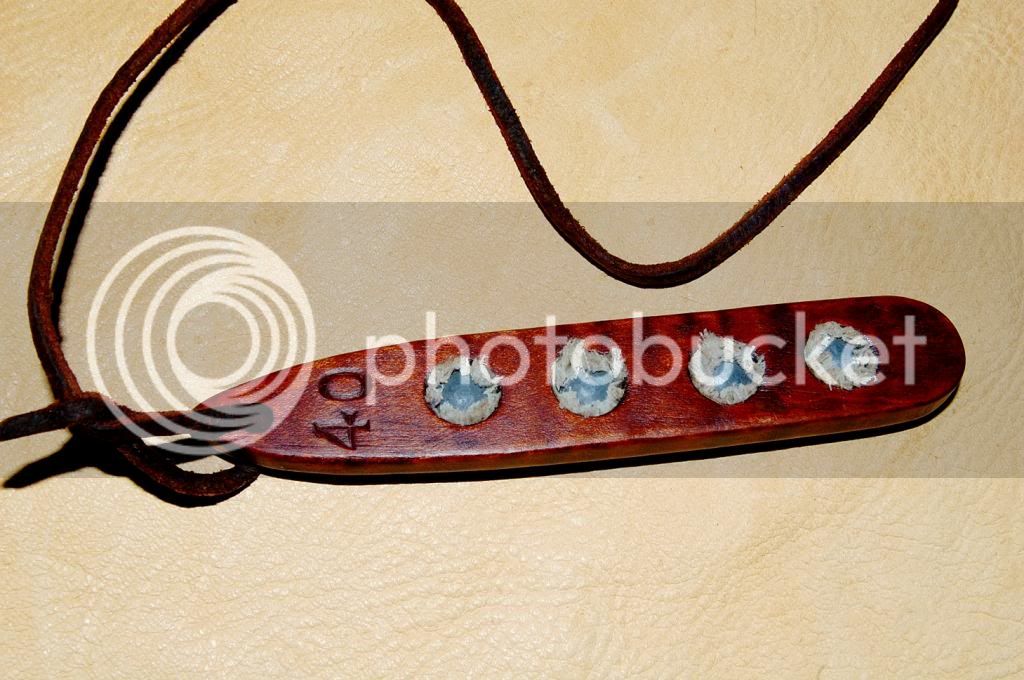

This is why I make mine on the thick side, this is 1/2" and is made for a .62

Really can be a problem with any thickness wood as long as dirt/debris can access lubed patch material.Alden said:Problem with a thin board is the "gooey" is out there to rub on everything and for everything to get all over it. SOMEtimes that won't matter...

I use little slip on suede sleeves like this:

- Joined

- Dec 25, 2011

- Messages

- 8,787

- Reaction score

- 3,778

I just used one of my regular ball and patch combinations that I shoot ,pulled some of my drill bits out close to that size and cut some holes in a block of wood and tried the fit.

Made a dandy one out of delrin for a friend for Christmas. I cut a counter bore on the underside that fit his guns muzzle so it made each block hole self aligning with his bore.

Don't have a picture to show but it would work with hard wood as well. Mike D.

Made a dandy one out of delrin for a friend for Christmas. I cut a counter bore on the underside that fit his guns muzzle so it made each block hole self aligning with his bore.

Don't have a picture to show but it would work with hard wood as well. Mike D.

ApprenticeBuilder

58 Cal.

- Joined

- May 27, 2006

- Messages

- 2,528

- Reaction score

- 189

New222 said:do I need a special drill bit for the holes, or would my metal cutting bit work ok? Sorry for all the questions.

Metal bits will work, you'll want to sneak up on final drill size to minimize the tear out associated with them, start several sizes smaller than finished size.

I used a forstner bit for the .62 as it just happens to correspond with 5/8"

skunkskinner

50 Cal.

- Joined

- Aug 10, 2005

- Messages

- 1,107

- Reaction score

- 2

Fits the hand betterAlden said:Y curved?

Similar threads

- Replies

- 2

- Views

- 401

- Replies

- 1

- Views

- 298

- Replies

- 1

- Views

- 319