I started rounding my fowler nose off this afternoon. Should the ramrod groove disappear near the place where the forend tapers or fade away on it's way to the nose?

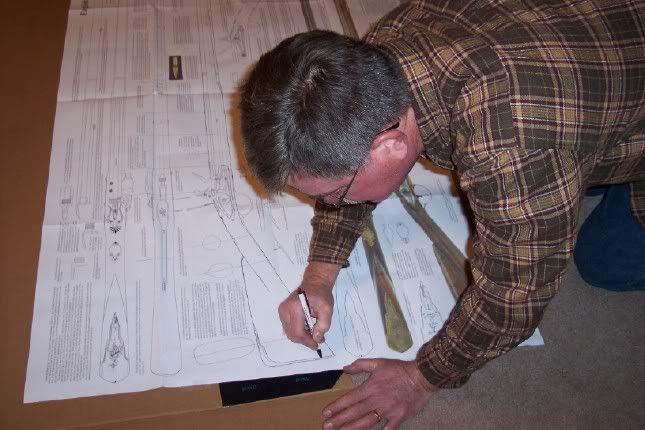

Here is where I stopped this afternoon.

Here is where I stopped this afternoon.