Jaan said:

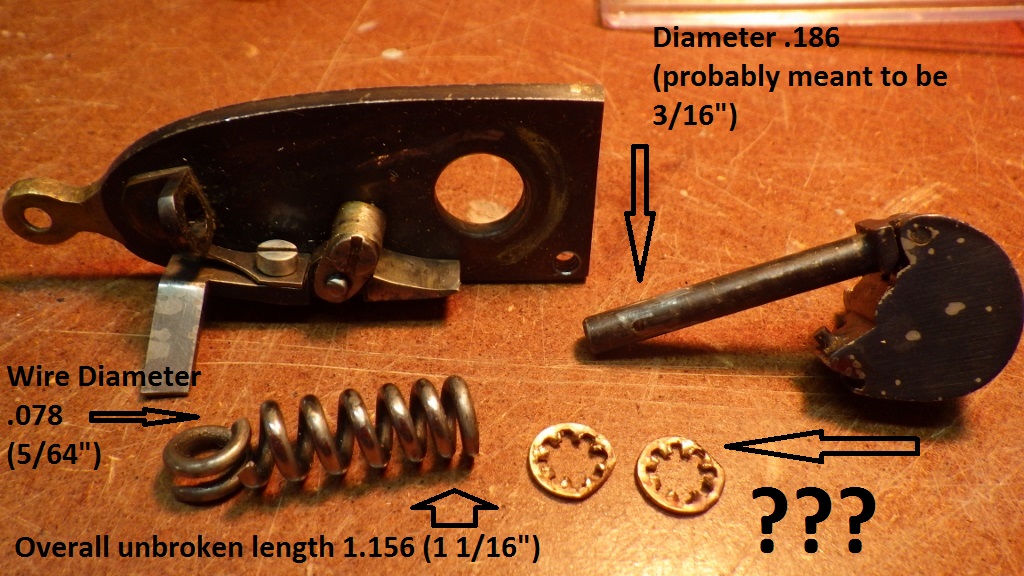

The thing about this spring is that I'm not sure if it's the "stock" spring or not. Are they supposed to fit lose, with a couple of washers on the end?

My experience with coil springs in guns is almost completely with modern guns. The springs are not only as long as the length of the space for them, BUT also a bit longer. IOW, you need to compress them to get them in the gun.

Jaan said:

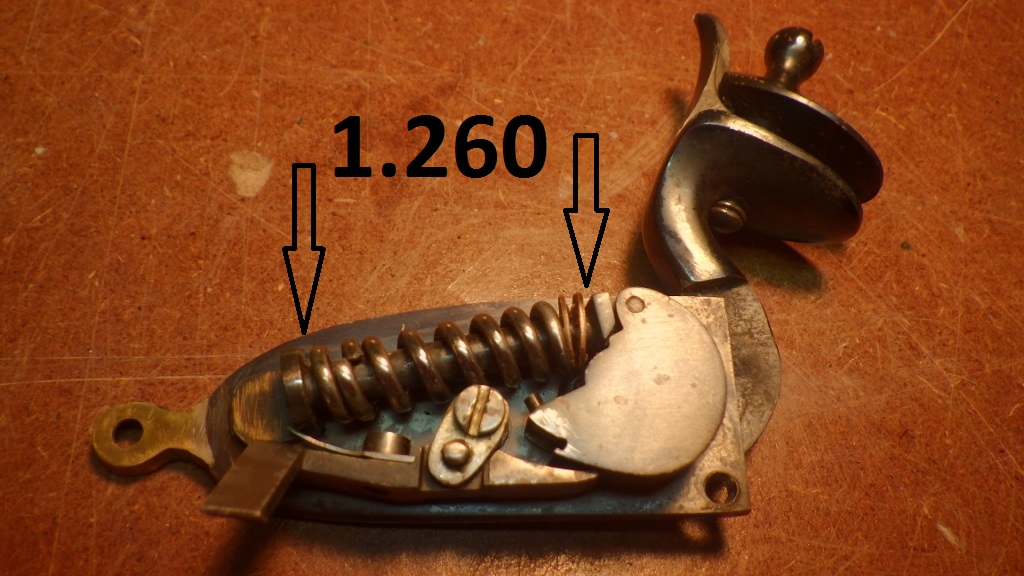

Here's what I actually have, notice that the full fired gap is more than the total spring length? Is that normal in a flintlock?

I don't believe that is normal in any gun. Actually and trying not to be unnecessarily unkind, but it looks like a Rube Goldberg attempt to fix the problem.

Coil Springs that are required to have the amount of pound/tension used like this are often, if not usually formed so there is a fairly flat coil on each end that is perpendicular to the length of the spring. The idea is that it puts fairly even pressure against the working surface/s. This spring is not only what powers the flint cock/hammer to go forward and cause the flint to make sparks; BUT it is also meant to keep the flint cock/hammer forward (under spring pressure) when the flint cock/hammer has gone all the way forward. That way the flint cock/hammer does not flop around when it is fully down.

I think this spring was cut from a longer length spring, so it does not have such flat coils on the end. I also THINK this is

part of the reason the washer/s were used - so the clipped coil might have put more even pressure against the parts. However, a solid washer or washers around the rod would have been better for that purpose. The other reason to put the washer/s in place was the spring was cut too short and that is how they closed up the distance in which the spring operated and/or give more tension to keep the flint cock/hammer down at the end of it's movement and not flop around.

The outer diameter of the coil spring may or even probably is important to ensure it has room to be compressed and then uncompress quickly and not rub against the lock plate.

I wonder if an M1 Garand Hammer Plunger Spring could be used as a replacement part, but I have to go measure the inside diameter and would also need the outside diameter of your spring.

Gus

There is a shop in Mcadam that boggles the mind with stock of 'seldom seens'

There is a shop in Mcadam that boggles the mind with stock of 'seldom seens'